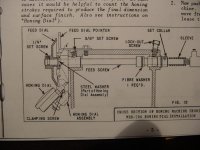

Hello gentlemen: I am new to this forum although I have been reading it for some time. I picked up an older Sunnen Hone (MBB-1290D) that is in good shape despite it's age. It did have a hand brushed paint job on it that would have embarrassed a garbage barge so I decided to strip her down and give it a good going over and a new coat of paint. I want to replace the spindle bearings while I have it apart but am having a little issue getting the spindle flanges off. I tried a little pressure with a jaw puller and bearing splitter but didn't want to get medival with it until I was sure how the flanges come off. Looking at the parts breakdown it looks as if they might screw on but it's not clear. Attached is a pic of the spindle in question. Thanks, Bill.