HurleyByrd

Aluminum

- Joined

- Jan 21, 2011

- Location

- WV United States

As John Oder, Mike C. and a few others know, I recently purchased a 1916/17 L&S 18" Selective Head lathe. I actually bought the whole shop and am in the process of cleaning it out. I thought the L&S DID NOT contain any other chuck than the 3 jaw scroll which was already attached.

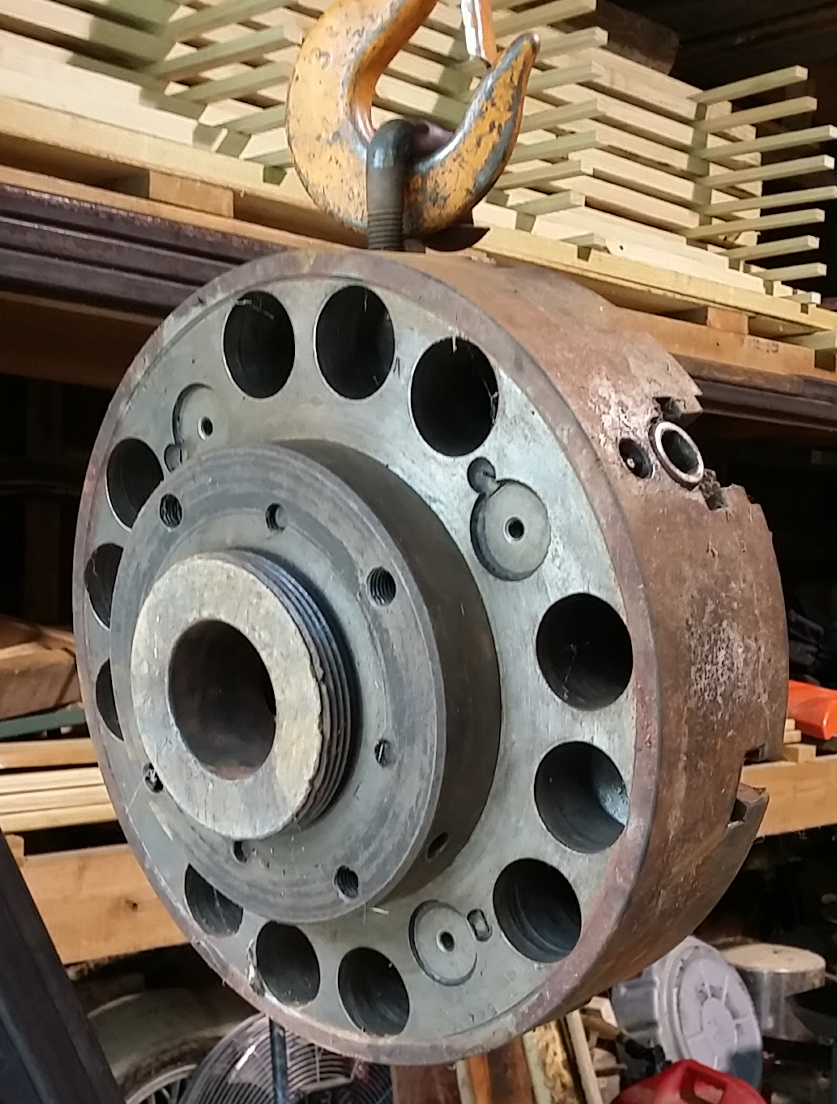

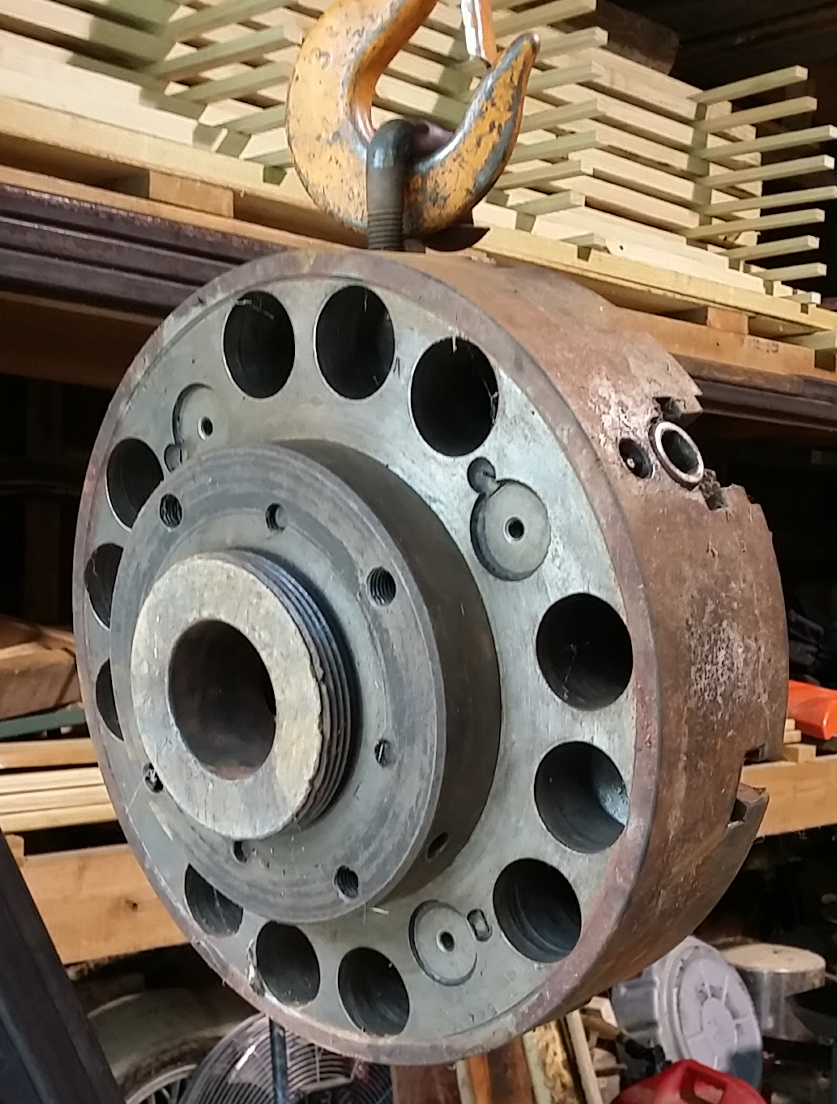

As I was rooting around, I found this 16" 4 jaw under a shelf, on the floor, thread side down hidden behind an anvil and am obviously pretty stoked about the find. Yet, before I even clean it.... I want some guidance so I do not cause any further harm.

How should I proceed in bringing this chuck back to life??????

By the way, I measured the mounting threads and come up with 6 TPI and a major diameter of 5.457". It appears there is an L&S Mount Plate with the chuck bolted to it and it was made by the Union Manufacturing Co.. Oh yeah..... it weighs 220 pounds plus 4.5 more for the wrench.

Thank you

Peter

As I was rooting around, I found this 16" 4 jaw under a shelf, on the floor, thread side down hidden behind an anvil and am obviously pretty stoked about the find. Yet, before I even clean it.... I want some guidance so I do not cause any further harm.

How should I proceed in bringing this chuck back to life??????

By the way, I measured the mounting threads and come up with 6 TPI and a major diameter of 5.457". It appears there is an L&S Mount Plate with the chuck bolted to it and it was made by the Union Manufacturing Co.. Oh yeah..... it weighs 220 pounds plus 4.5 more for the wrench.

Thank you

Peter

Do I NOT have to worry about further damaging the internals of jaws by working them out? Just lube the crap outta them and begin working them back and forth?

Do I NOT have to worry about further damaging the internals of jaws by working them out? Just lube the crap outta them and begin working them back and forth?