I’ve acquired a Hendey lathe for the irresistible price of free. The caveat is that I need to move it out of a basement through a bulkhead. It’s going to be an interesting journey! First step is stripping a few things off to make it slightly more compact and a few pounds lighter. Then I think I have someone with a backhoe to actually pick it out of the bulkhead and place it on a trailer... Question for the experts though. I would like to remove the apron and I’ve seen a few videos were the lead screw bracket on the right hand side is unbolted and then the bracket is slid off the screw and the apron can then be run right off the end of the lathe bed. I’m looking at the end of the lead screw and there appears to be a cap threaded onto the lead screw that will not allow the bracket to just slid off. In addition to being threaded on it has what I thought was a set screw in the side of it but upon digging the crud out of the hole it looks more like a pressed in pin... Does that sound right? If that’s the case I see no way to remove without drilling the pin... Looking for advice. As this doesn’t seem like very “service friendly” construction. Maybe I’m missing something.

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

14x30 Hendey Lathe lead screw bracket and end cap

- Thread starter Matl59

- Start date

- Replies 11

- Views 2,029

johnoder

Diamond

- Joined

- Jul 16, 2004

- Location

- Houston, TX USA

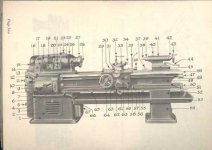

48 is screw, 47 is bracket - no cap

Older is similar, just dual purpose bracket

I'd suggest taking out two screws coming in from top and see what you have then

The idea is fine as long as you don't bend the screw. Bracket needs to be back on as soon as apron passes, and you need to hold screw up before its ever unsupported

Before you ever start, assure yourself the key way in the screw actually goes all the way to the right end

Be aware on the cone head (like your photo) the lead screw passes thru the entire QC box and its cone of gears and has a nut far left end. This can be a REAL BEAR to remove if that was contemplated

Older is similar, just dual purpose bracket

I'd suggest taking out two screws coming in from top and see what you have then

The idea is fine as long as you don't bend the screw. Bracket needs to be back on as soon as apron passes, and you need to hold screw up before its ever unsupported

Before you ever start, assure yourself the key way in the screw actually goes all the way to the right end

Be aware on the cone head (like your photo) the lead screw passes thru the entire QC box and its cone of gears and has a nut far left end. This can be a REAL BEAR to remove if that was contemplated

Attachments

Last edited:

Froneck

Titanium

- Joined

- Dec 4, 2010

- Location

- McClure, PA 17059

I have a 14X301950 vintage, gear drive not flat belt. My lead screw fits in a coupler with tapered pins, I assume it's keyed. If you have the same as mine I can look to see if carriage will come off the end. I know on some lathes the rack has no teeth on the very end. Not sure how my 14X30 is but I can check if requested.

Froneck

Titanium

- Joined

- Dec 4, 2010

- Location

- McClure, PA 17059

I have the same gear drive lathe as in the photo. I never had the carriage off but I can check tomorrow to see if it can be removed. It's not light! I did have the carriage off my P&W 16" I used a forklift. The 14" Hendey is smaller but not by much! Actually I took the Apron off then the carriage, I could not lift either one.

johnoder

Diamond

- Joined

- Jul 16, 2004

- Location

- Houston, TX USA

reggie_obe

Diamond

- Joined

- Jul 11, 2004

- Location

- Reddington, N.J., U.S.A.

The 14X30 tie-bar Hendey that SouthBendMod34, myself and others disassembled and moved from a basement to the Ag. Museum had a threaded end on the leedscrew as well.

RCPDesigns

Hot Rolled

- Joined

- Sep 3, 2014

- Location

- Atlanta GA.

Mine definitely has a threaded lead screw. You need to make a spanner to remove it or, like the previous owner did, maul the heck out of it with vise grips. When you put this back together note that you tighten it such that the bearing on the other side removes the end play. Make sure the oil passage ways are clear as well and don't forget to lubricate as you run it. The lathe has a total loss oil system so be aware of that.

Attachments

Last edited:

Ok, I finally got back over to the lathe. The cap unscrewed without much fight. I was able to remove the two screws on top of the bed holding the bracket and removed that along with a spacer as well. On the lead screw side of that bracket there is what I thought was another spacer that would just slip off but it appears that maybe its press fit? Any insight would be helpful. I didnt have a gear puller with me so I didnt mess with it too much. Is this the way to go? I dont want to mangle anything. So close. Just need to get that peice off and I can remove the apron. Also realized I may have miss-identified it. Think its actually a 16inch model.

hendeyman

Stainless

- Joined

- Nov 18, 2005

- Location

- elfrida arizona usa

Mat159:

You don't need a gear puller to remove the Thrust Washer. Soak the area in penetrating oil and clean the area from the washer to the end of the shaft with steel wool. Take a piece of hardwood and tap the washer off the shaft. If you measure the Leadscrew at the threaded portion you will get 1-1/4 inches and the portion that the Washers fits on is 15/16 inches. the right hand end of the Leadscrew is threaded 15/16" x 14. Originally, the left hand end was not threaded after passing through the Gear Box, but a later date, it had a filler piece and a Thrust Washer. The thrust washer is held in place by a set screw and is unscrewed with a Pin Spanner. The right hand nut is also removed using a pin spanner.

All of the posters have giving excellent advice about removing the Apron, but I would like to add a bit more. Even through this is a

Single Walled Apron and not a Double Walled Apron, it is still heavy and may cause problems getting it off the Leadscrew. To make the

job a bit easier, I arrange a "creeper" under Apron with a small scissor jack mounted on the creeper. Before the Apron can be removed,

it will be necessary to remove all of the shaft brackets. Don't forget the Automatic Stop rod bracket located under Apron as well as

the one located at the end of the Bed. With both Auto Sop Rod brackets removed, crank the Apron to the end of the Bed. Adjust the creeper jack to where it just supports the bottom of the Apron. Within a foot of the left hand side of the Apron, tie up all three

shafts with cord or whatever is handy. This will support the shafts, but it will also allow you to move them about as you remove the

Apron. Next remove the four bolt that secure the Apron to the Carriage. It will be necessary, in most cases, to move the Cross Slide

in a bit to find the "hidden" Screw Head. With the bolts loose but not remove, lower the Apron with the jack. Using a flashlight to

see the Cross Feed Gear, keep lowering until the Gear clears the bottom of the Carriage. At this point, you can remove the bolts and start sliding the Apron past the end of the bed, clearing the Half-Nuts by moving the end of the Leadscrew up or down. Make any vertical adjustments necessary using the jack. Two more things you need to keep in mind, make sure that you clean the Featherway and apply penetrating oil. This will help to prevent jamming of the Worm Keys in the Featherway. Don't forget to remove the Reverse Shaft Bracket and Handel from the Apron before removing the Apron. When you have the Apron off the lathe, this would be a good time to check for worn parts, particularly the Worm Keys.

Hendeyman

You don't need a gear puller to remove the Thrust Washer. Soak the area in penetrating oil and clean the area from the washer to the end of the shaft with steel wool. Take a piece of hardwood and tap the washer off the shaft. If you measure the Leadscrew at the threaded portion you will get 1-1/4 inches and the portion that the Washers fits on is 15/16 inches. the right hand end of the Leadscrew is threaded 15/16" x 14. Originally, the left hand end was not threaded after passing through the Gear Box, but a later date, it had a filler piece and a Thrust Washer. The thrust washer is held in place by a set screw and is unscrewed with a Pin Spanner. The right hand nut is also removed using a pin spanner.

All of the posters have giving excellent advice about removing the Apron, but I would like to add a bit more. Even through this is a

Single Walled Apron and not a Double Walled Apron, it is still heavy and may cause problems getting it off the Leadscrew. To make the

job a bit easier, I arrange a "creeper" under Apron with a small scissor jack mounted on the creeper. Before the Apron can be removed,

it will be necessary to remove all of the shaft brackets. Don't forget the Automatic Stop rod bracket located under Apron as well as

the one located at the end of the Bed. With both Auto Sop Rod brackets removed, crank the Apron to the end of the Bed. Adjust the creeper jack to where it just supports the bottom of the Apron. Within a foot of the left hand side of the Apron, tie up all three

shafts with cord or whatever is handy. This will support the shafts, but it will also allow you to move them about as you remove the

Apron. Next remove the four bolt that secure the Apron to the Carriage. It will be necessary, in most cases, to move the Cross Slide

in a bit to find the "hidden" Screw Head. With the bolts loose but not remove, lower the Apron with the jack. Using a flashlight to

see the Cross Feed Gear, keep lowering until the Gear clears the bottom of the Carriage. At this point, you can remove the bolts and start sliding the Apron past the end of the bed, clearing the Half-Nuts by moving the end of the Leadscrew up or down. Make any vertical adjustments necessary using the jack. Two more things you need to keep in mind, make sure that you clean the Featherway and apply penetrating oil. This will help to prevent jamming of the Worm Keys in the Featherway. Don't forget to remove the Reverse Shaft Bracket and Handel from the Apron before removing the Apron. When you have the Apron off the lathe, this would be a good time to check for worn parts, particularly the Worm Keys.

Hendeyman

Thanks for the pointers. I actually have the apron bolted to an engine leveler and held up by an engine hoist so I’m prepared for the weight  The thrust washer was sprayed down with penetrating oil before I left. I’ll clean up the shaft as suggested and hopefully I can tap it free on my next visit.

The thrust washer was sprayed down with penetrating oil before I left. I’ll clean up the shaft as suggested and hopefully I can tap it free on my next visit.

The thrust washer was sprayed down with penetrating oil before I left. I’ll clean up the shaft as suggested and hopefully I can tap it free on my next visit.

The thrust washer was sprayed down with penetrating oil before I left. I’ll clean up the shaft as suggested and hopefully I can tap it free on my next visit.Similar threads

- Replies

- 23

- Views

- 1K

- Replies

- 20

- Views

- 1K

- Replies

- 13

- Views

- 583

- Replies

- 17

- Views

- 1K

- Replies

- 12

- Views

- 719