So does anyone have a shaper they can get some pics of the mounting for the vise of? I would love to have something to compare to if I need to fabricate something.

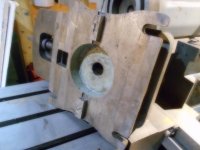

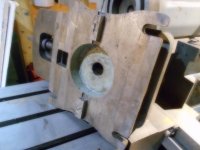

Here's the underside of a 12" Sheldon shaper's OEM vise.

Note the two rectangular keys position it ONE WAY ONLY and that they are secured by screws.

If one needs any

other angle, they are

removed.

There IS a "center hole", BUT even if you open the jaws and place a low-head fastener there, the vise is MEANT to have one or more of the four "ears" aligned with Tee slots on some diagonal angle to do the "real" holding job.

Simple. Good enough for basic shaper working.

Ingenuity, angle plates, dividing heads, yadda, yadda.. the limit, otherwise.

That's why shaper tables have tee slots on the SIDE as well as the top!

Some days? Yah just have to "get creative"!

CAVEAT: "Heavy" cuts not recommended, anything but the keys-in, all four corners soundly secured position.

Not really an issue if doing "detail work". Just take smaller bites, use more strokes. Not all that much stress need be involved.

A shaper's main resource comes from between the operator's ears.

PATIENCE!