tommy1010

Stainless

- Joined

- Apr 21, 2010

- Location

- northeastern Pa, USA

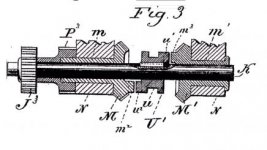

Putting a 16" conehead headstock back together. The question I have is: Are the reversing gears timed to one another? As you can see in the pics I installed them with the single cogs lined up. I am pretty sure that is the way I removed them. But I could be wrong. The sliding reverser has the cogs 180 degrees out as shown in the pics. There are no timing marks on any of the gears. Maybe too early for such a thing. Does it matter? If I got them wrong I can easily change the arrangement now before I move along. Don't fret over the red paint. No one will see it. Just for rust prevention. Maybe Hendyman can shed some light here!!!