Asquith

Diamond

- Joined

- Mar 3, 2005

- Location

- Somerset, UK

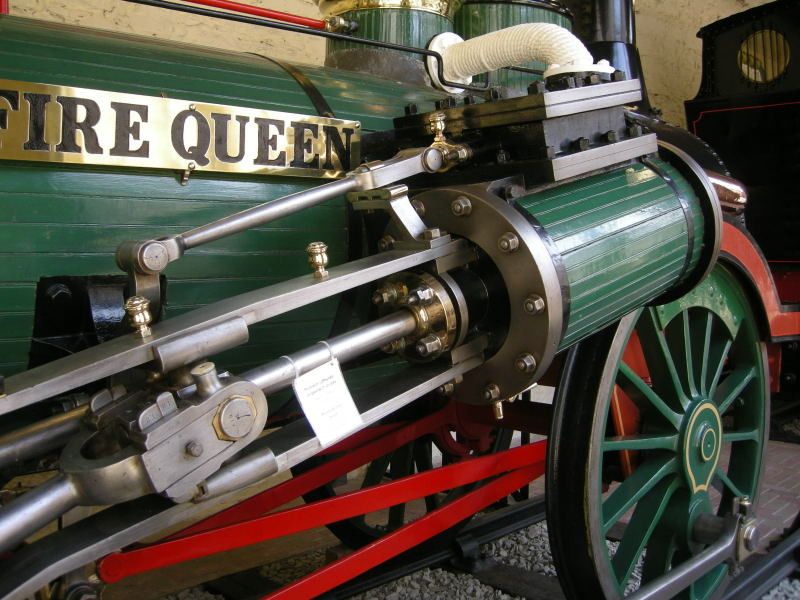

Fire Queen, built in 1848 by A Horlock & Co of Northfleet, Kent (near London), for the Padarn Railway in North Wales. It was used on a 4 ft gauge line at Dinorwic slate quarry.

Apparently it was one of only two locomotives built by the company. Remarkably, after it was replaced by more modern locos in the 1880s, it was preserved by its owners, but seen by few people. In 1969 it was moved to its current location, the railway museum at Penrhyn Castle.

http://www.nationaltrust.org.uk/penrhyn-castle/things-to-see-and-do/

More of this castle, and of the local slate industry later. Meanwhile, some details:-

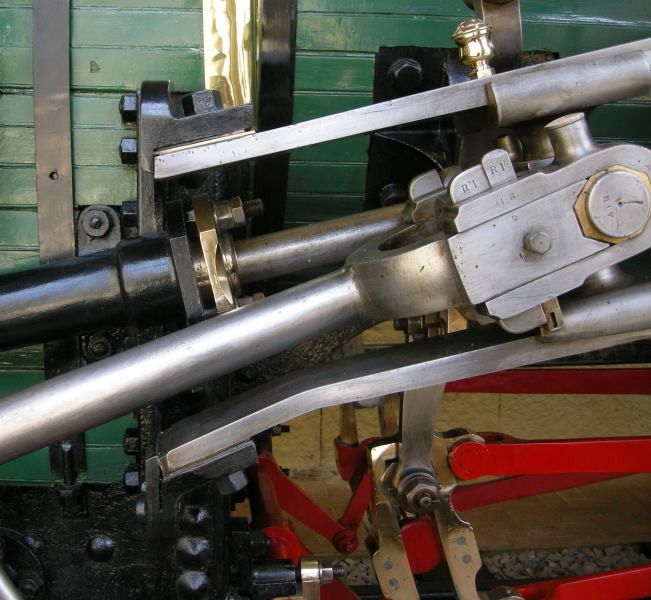

Note the way the regulator rod circumnavigates the safety valve cover!

An unusual feature is the lack of a frame. Everything was bolted to the boiler (as on traction engines). Another oddity is the long wheelbase (for an 0-4-0 loco). Obviously the boiler was going to expand a lot more than the coupling rods!

I suspect that these wheels were fire-welded from numerous pieces. If so, very fine examples of the blacksmith’s art.

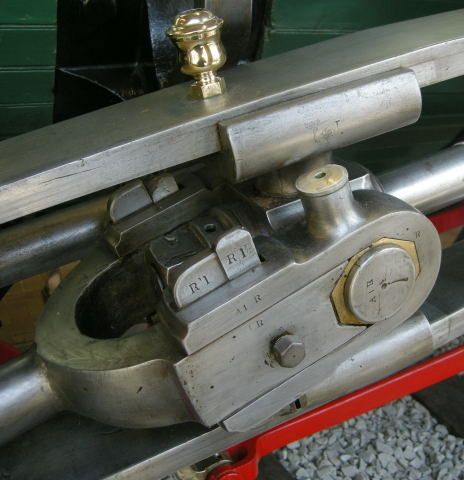

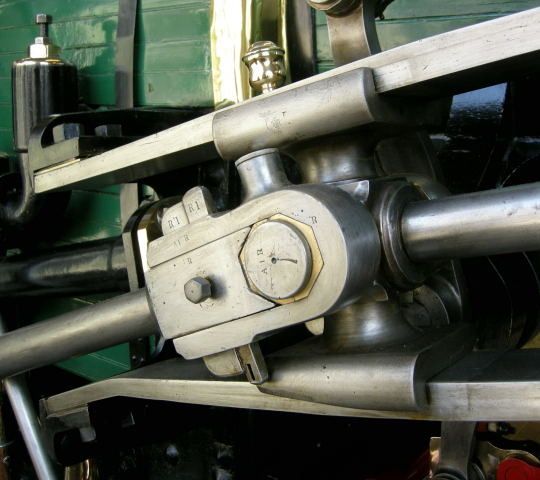

Stephensons’ link motion: unusually, the expansion links are made of brass or bronze, with steel liners at the ends.

Typical of the sort of slag inclusions that the blacksmith was faced with.

More to follow.