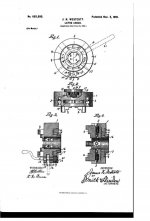

I believe the OP has what is known as a "Combination Chuck". These were built by Oneida or Westcott and were fairly common ages ago. My guess is that the combination chucks were supposed to allow a lathe operator to have one chuck that could serve as both a 'universal' or 'scroll' chuck and, could also serve as an 'independent' chuck'. The 'scroll chuck' is, at least in theory, self-centering. In actuality, a scroll type chuck will rarely run true, and at best within a couple of thousandths. This was addressed in later years by the 'Set True' type of chuck back plate, which lets a scroll chuck be adjusted so a job runs true. The 'independent' chuck has the ability to chuck odd shapes of work as well as to be adjusted so the work runs dead true (concentric with the centerline of the spindle).

Oneida, or Westcott, was trying to capture the best of both types of chuck in one single chuck. The combination chuck went one better on the 'Set Tru' types, as it allows the individual jaws to be adjusted to hold a particular size/shape of work and the job can then be centered. Once this is done, if multiple jobs of the same shape need to be run, they will (at least in theory) run true as well.

The idea of the combination chuck is a good one in theory. How well these chucks actually perform in terms of chucking multiple jobs with repeat accuracy is something I wonder about. I have a 4-jaw Oneida chuck on my LeBlond lathe. The body casting could have been used to make a 'combination' chuck, but was built as a basic 'independent' 4 jaw chuck. On the face of the chuck body, the word "special" is stamped. My guess is Oneida was probably making more of the combination chucks on that size body casting, so a plain 4 jaw chuck was 'special'. I also have a "Westcott" S-shaped heavy adjustable wrench hanging in my shop. I bought it as new-old-stock when I was a kid of about 12 (58 years ago). The name "Westcott" is forged into the handle of the wrench, but the maker's name is "Oneida Chuck Company".