Hemifish69

Plastic

- Joined

- May 25, 2016

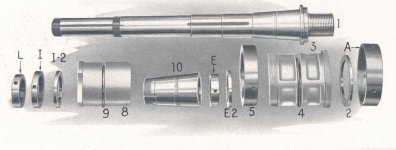

I'm stumped. 3 years ago I pulled apart my locked up hendy to fix the broken oil ring on the big end, and shim the spindle. It took a porta power to get the spindle out, and going back together, I'm getting stuck at 4" out. I wasn't going to force it, so I walked away in 2017 and got caught in nother projects.

Took a fresh look at it and I'm still stumped on reassembly. I took pictures, wrote notes, lost no pieces. But still the spindle won't slide home. And yes, all the keys are lined up.

The bed of the lathe is in fine shape. I'm considering building a new drive end with tapered roller bearings in a welded support carrying the original spindle. People make lathes from scratch on YouTube. Why not bring this lathe back with a modern twist? Thoughts?

Took a fresh look at it and I'm still stumped on reassembly. I took pictures, wrote notes, lost no pieces. But still the spindle won't slide home. And yes, all the keys are lined up.

The bed of the lathe is in fine shape. I'm considering building a new drive end with tapered roller bearings in a welded support carrying the original spindle. People make lathes from scratch on YouTube. Why not bring this lathe back with a modern twist? Thoughts?