Hi there,

First time posting to the site, but have been lurking for some time.

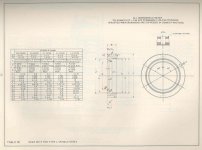

My question is, i have an old LeBlond lathe, i believe 1940's, See attached pic.

I want to replace the 4 jaw chuck with a 3 jaw chuck, however i do not know what to ask for, specifically the thread connections etc.

What additional information do i need to provide to find the answer, Or who I could talk to that maybe able to help.

Does anyone know where i could find a 3 jaw chuck for this beast. I am in the Houston area if that makes a difference.

Thanks in advance.

First time posting to the site, but have been lurking for some time.

My question is, i have an old LeBlond lathe, i believe 1940's, See attached pic.

I want to replace the 4 jaw chuck with a 3 jaw chuck, however i do not know what to ask for, specifically the thread connections etc.

What additional information do i need to provide to find the answer, Or who I could talk to that maybe able to help.

Does anyone know where i could find a 3 jaw chuck for this beast. I am in the Houston area if that makes a difference.

Thanks in advance.