NAST555

Stainless

- Joined

- May 23, 2008

- Location

- Gauteng, South Africa

I suppose not really antique but interesting to me.

This shaper has been with me for about 4 years. It used to sit in the main shop and I messed around with it a bit, made a few rough V-blocks, and then it was forgotten. I walked past it the other day and decided to move it into my new shop and get it up and running and for apprentices to use it a bit.

I tried to do some research on year of manufacture but nothing has come up. It came out of a training college and was probably hardly ever used. I think my playing around with it is pretty much the most use it has seen since it was bought.

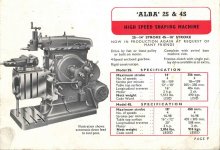

Any idea on how to date it? It seems you got two variants of them and this one is the sturdier Alba full cast body that apparently was done away with on some of the later Elliot models but mine was obviously bought after Elliot had bought Alba.

This shaper has been with me for about 4 years. It used to sit in the main shop and I messed around with it a bit, made a few rough V-blocks, and then it was forgotten. I walked past it the other day and decided to move it into my new shop and get it up and running and for apprentices to use it a bit.

I tried to do some research on year of manufacture but nothing has come up. It came out of a training college and was probably hardly ever used. I think my playing around with it is pretty much the most use it has seen since it was bought.

Any idea on how to date it? It seems you got two variants of them and this one is the sturdier Alba full cast body that apparently was done away with on some of the later Elliot models but mine was obviously bought after Elliot had bought Alba.