I purchased this mill last year to restore, I'm finally going to pick it up this weekend, there is little information on these mills and I can't find anything specific to this particular model, I'm guessing it's 1920s possibly older.

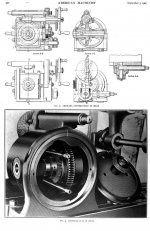

The thing that throws me off is the gears on the back vs the belts used on most of these machines built around in the early 1900s, maybe an upgraded version of the No.25? Then again it has both Becker and Brainard on the side vs Becker Machining Co. I believe I read these two companies teamed up then became Becker Machining Co. Around 1906, so with both names on it has me questioning the date as well.

Anyways I'm just excited to go get this beast of a machine home and start restoration, any thoughts, opinions, or information is more than welcome.

This is my first mill and probably the largest machine I have attempted to restore to date.

Thanks

Eric

The thing that throws me off is the gears on the back vs the belts used on most of these machines built around in the early 1900s, maybe an upgraded version of the No.25? Then again it has both Becker and Brainard on the side vs Becker Machining Co. I believe I read these two companies teamed up then became Becker Machining Co. Around 1906, so with both names on it has me questioning the date as well.

Anyways I'm just excited to go get this beast of a machine home and start restoration, any thoughts, opinions, or information is more than welcome.

This is my first mill and probably the largest machine I have attempted to restore to date.

Thanks

Eric

Last edited: