Adapters (back-plates) can be made.

Your lathe part/spindle/nose thread may or may not be a "standard" size. Many, perhaps most were not. You can use a micrometer (digital vernier will do nicely) to get a read on the OD of the threads, and a "thread pitch gauge" will allow you to determine the threads per inch. Or failing in this second, you can correlate the threads you see which may be less than an inch total to what it would be IF it were to continue for that inch. I.e. 4 threads in 1/2 inch correlates to 8 threads per inch. Looking at standard charts online you should be able to tell if something is close.

If you find the threads ARE a standard size, you potentially could do this work - drilling a hole and threading a round backing plate using a standard tap - in a drill press. A lathe would be better.

If you find the threads don't seem to match anything "standard" then you're forced into using the spindle from your head stock as a go-no go gauge and cutting the threads single point tool style in the traditional inside (female) nut threading practice which has been done on lathes for generations. Take a cut, try the spindle for fit, take another cut until it does.

Were you to have a complete lathe I would say you could use your lathe and a face plate to make another backing plate - the only challenge is in the testing for fit - you have to unscrew both face plate and backing plate TOGETHER without changing the two plates positions relative to each other - turn it end for end and try the female thread you just cut on the spindle you just used to make the cut.

Since you do not have this luxury you'll have to find another lathe and possibly an operator skilled in its use to do this using your spindle as a model. He will thank you for having the loose spindle as this makes the task easier. Likely he understands how this is done as it is not uncommon in trade education to do this as training exercise according to method of one paragraph up.

It IS a challenge. But nothing is quite so satisfying as making something using your own hands, mind and developed skill. Sometimes you have to develop what you don't have of these three to make it happen.

But there is the challenge AND the satisfaction.

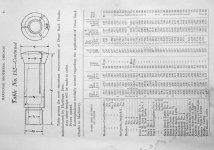

A good book online describing basic operations on the lathe and other machine tools is "Advanced Machine Work" by Robert H. Smith. Not necessarily so advanced, it describes by using good pictures and narrative most of what you need to know.

http://www.opensourcemachinetools.org/archive-manuals/advanced-machine-work.pdf

Joe in NH