Serial number 20606

I've been looking for a lathe I could afford for a bit now. Kinda wanted an older atlas or craftsman cause it would do pretty much everything I would need but ran across a hendey on cl. 500 bucks later it's in my garage. Now, my knowledge on lathes, especially old ones is limited. I've run the cheap Chinese benchtop one at work to build some custom car parts, but I'm not a machinist. I do try and learn as much as I can though.

So the backstory on the lathe. A couple of brothers sold it to me. It was in there dads shop that looked like it hadn't been used in 20 years. The building was still standing, but that's about it. The roof was full of holes, windows were boarded up, etc. I guess there dad would never let them in there, but he had Alzheimer's and was going into a home so they were selling off all the stuff to pay for it.

There was about an inch of dirt on the Hendey sitting there in the middle of the shop, but underneath all that dirt I could see oil. All the handles had surface rust but when I spun them everything moved nice and free even with all that dirt the oil had collected over time. The chip tray, which stored the tooling, had collected water and was pretty rusty along with everything in it. The whole thing looked like it just needed a cleaning and fluid change.

Well fast forward, I get it home and in some light and I can start to see she is in a little rougher condition then I had thought. I still want to get it going again, but not a full tear down.

Soooooo

I have a few questions. Keep in mind I've only used small China lathes before.

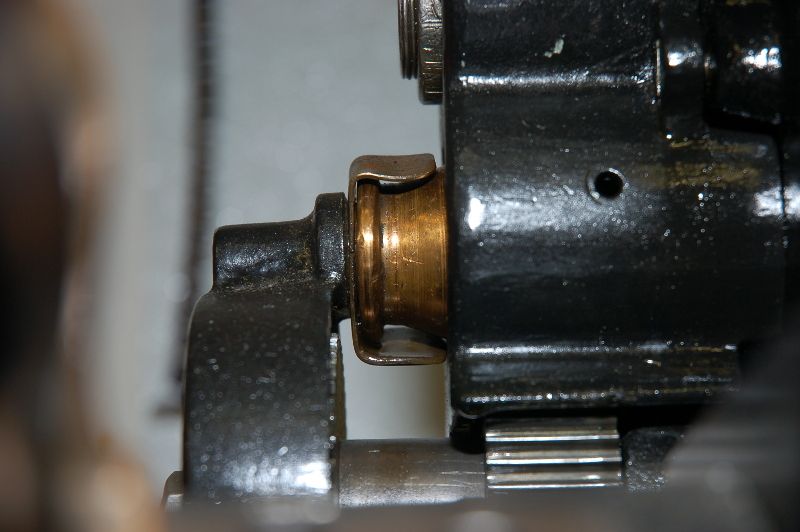

There is a lever behind the head stock on the operators left side. What does it do?

How much force is needed to turn the chuck by hand? I can rotate it around but takes some force and stops immediatly.

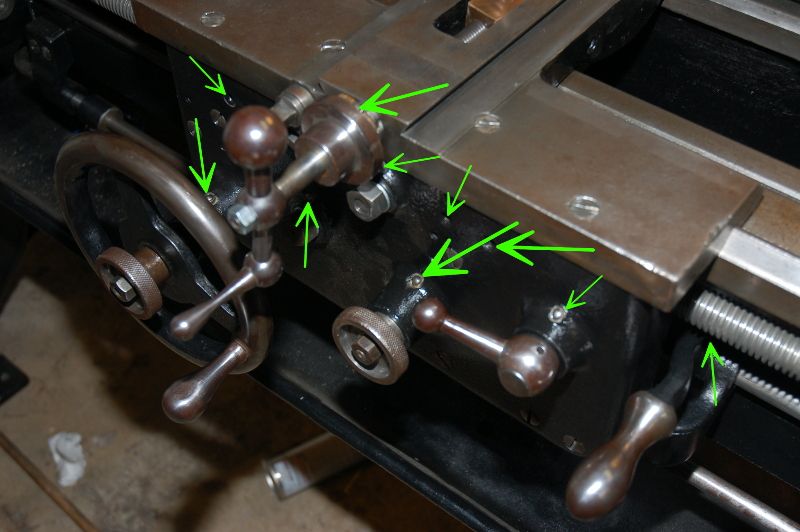

It looks like the carriage is the only place that might hold oil? There are a tone of little thumb screws that look like oil passages when you take them out. Do you have to hand oil all the bearings?

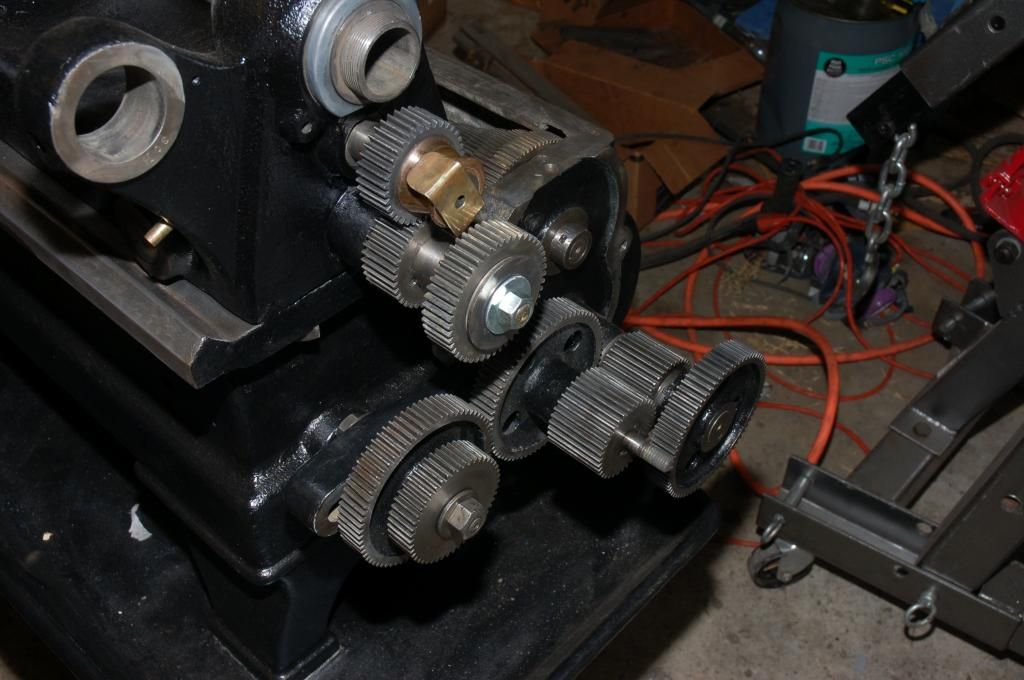

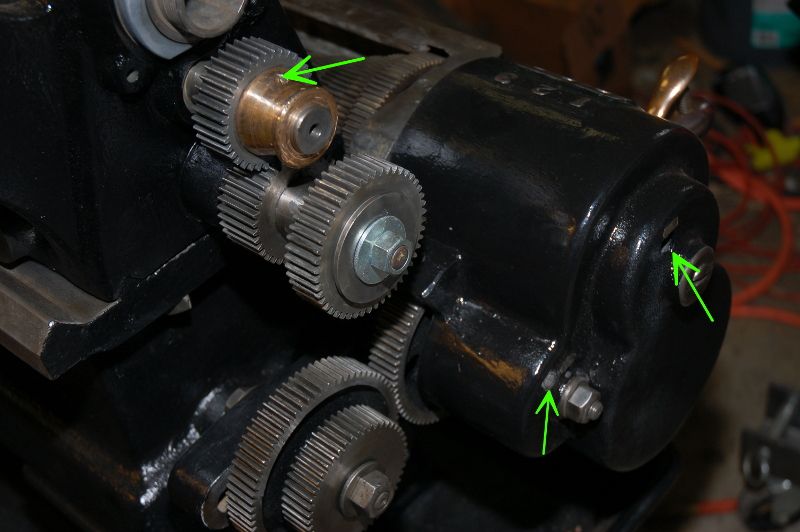

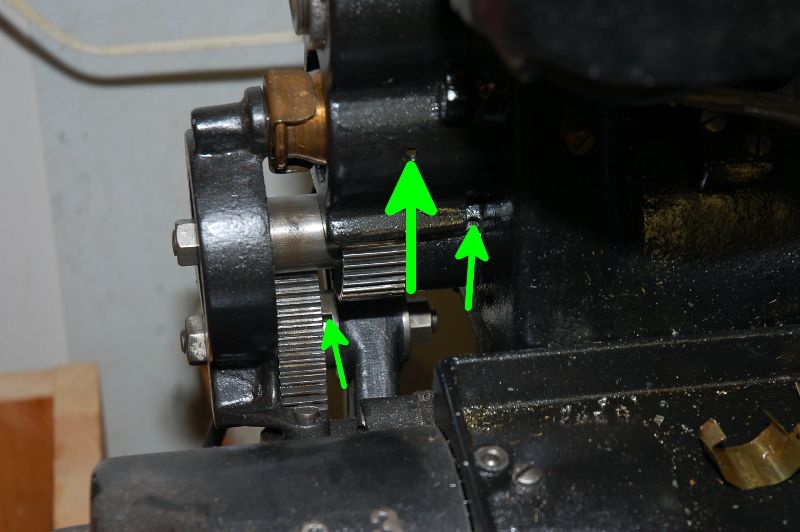

The gear in the middle of this 3 gear set moves back and forth. Is it suppose to?

free screen capture software

There were a couple of gears stuck to the shafts I had to free up but everything in the back is now at least moving.

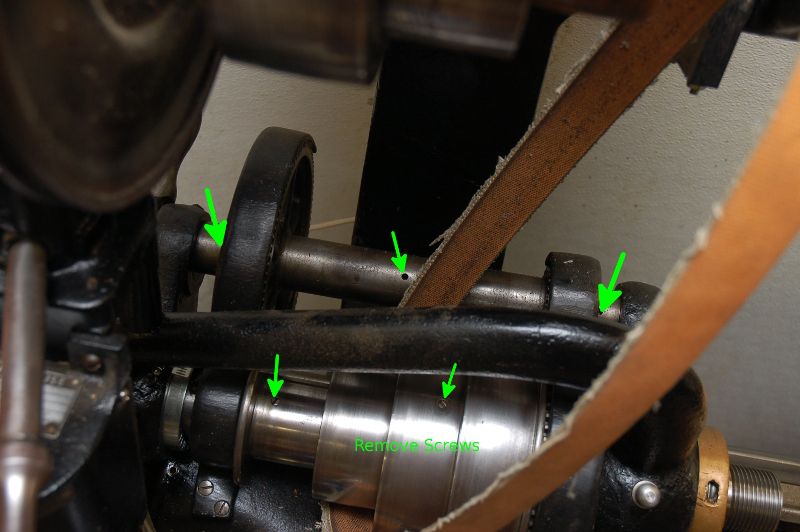

What are some things I should check and do before I run it under power?

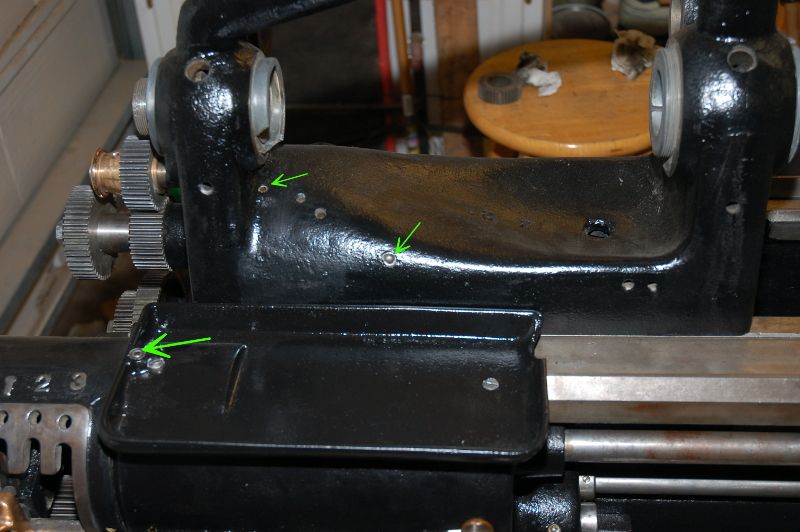

Here are a few more pics of the lathe

As I found her

image url

Loading it up

image sharing

I've been looking for a lathe I could afford for a bit now. Kinda wanted an older atlas or craftsman cause it would do pretty much everything I would need but ran across a hendey on cl. 500 bucks later it's in my garage. Now, my knowledge on lathes, especially old ones is limited. I've run the cheap Chinese benchtop one at work to build some custom car parts, but I'm not a machinist. I do try and learn as much as I can though.

So the backstory on the lathe. A couple of brothers sold it to me. It was in there dads shop that looked like it hadn't been used in 20 years. The building was still standing, but that's about it. The roof was full of holes, windows were boarded up, etc. I guess there dad would never let them in there, but he had Alzheimer's and was going into a home so they were selling off all the stuff to pay for it.

There was about an inch of dirt on the Hendey sitting there in the middle of the shop, but underneath all that dirt I could see oil. All the handles had surface rust but when I spun them everything moved nice and free even with all that dirt the oil had collected over time. The chip tray, which stored the tooling, had collected water and was pretty rusty along with everything in it. The whole thing looked like it just needed a cleaning and fluid change.

Well fast forward, I get it home and in some light and I can start to see she is in a little rougher condition then I had thought. I still want to get it going again, but not a full tear down.

Soooooo

I have a few questions. Keep in mind I've only used small China lathes before.

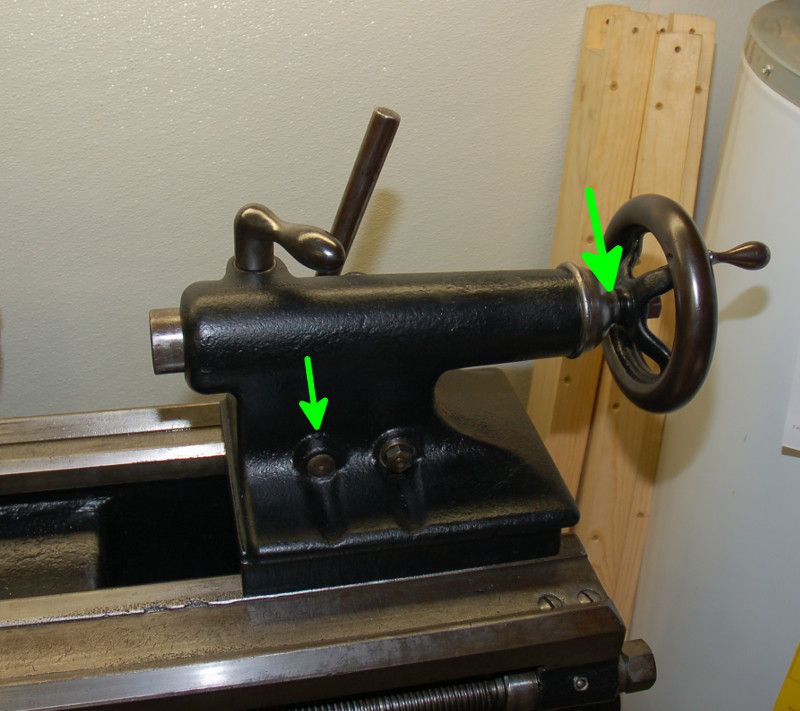

There is a lever behind the head stock on the operators left side. What does it do?

How much force is needed to turn the chuck by hand? I can rotate it around but takes some force and stops immediatly.

It looks like the carriage is the only place that might hold oil? There are a tone of little thumb screws that look like oil passages when you take them out. Do you have to hand oil all the bearings?

The gear in the middle of this 3 gear set moves back and forth. Is it suppose to?

free screen capture software

There were a couple of gears stuck to the shafts I had to free up but everything in the back is now at least moving.

What are some things I should check and do before I run it under power?

Here are a few more pics of the lathe

As I found her

image url

Loading it up

image sharing