PumpkinGuy

Plastic

- Joined

- Dec 2, 2018

Hi everybody. I hope I'm posting this in the right place. The for sale section was pretty emphatic about antique tools being prohibited. This is as much an adoption as a sale anyway, in terms of my intention.

I work occasionally with a wonderful little machine shop in Pawcatuck CT that's been in business in the same building, with some of the same machinery, for over a century. They're hard working, nice, adaptive guys maintaining a family business whose customer base looks radically different than it did 100 years ago. They needed to add a couple new computer controlled machines, and without a postage stamp of extra real estate in their building, some of the old stuff needed to go. I pulled up one day to find two beautiful old belt driven machines out on the curb. The owners told me that they had tried numerous avenues to find homes for both, even contacting industrial themed bars etc, but had been unsuccessful. The larger one, a surface grinder, had been damaged badly during lifting, but the smaller cylindrical grinder was in good shape. They were headed to the trash, and although I don't know much about the belt drive world, they were too beautiful not to try to save, so I turned my day around, and made a deal with the owner to buy and move the cylindrical grinding machine for scrap value, $100.

I briefly dreamt about using it one day, but it's just not a reasonable thing for me to keep in my life right now. I have so many other projects, work, hobbies, relationships, and very limited resources, not the least of which is storage space. To continue storing this machine in my neighbors barn for the possibility that I might one day set up a belt driven shop and need a cylinder grinder is unreasonable. But I want to find it an owner that can use it, or at least display it properly, and knowledgeably.

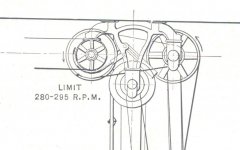

Its roughly 4 feet wide and tall, and two deep. It's set up somewhat like a lathe, a sliding deck on top of a tall cabinet, with two movable rotating pointed holders to hold the spinning work, but the tool that comes in to the side of the work is a grinding wheel. I was made by the Brown and Sharpe manufacturing company of Providence RI, and supposedly bought by the shop that sold it to me in 1916. Patent dates cast in range from 1897-1908. It was in good condition when I bought it, with evidence of recent use and respectful maintenance. Things are generally tight and smooth, and seem to all be present, though I really wouldn't know. Unfortunately, within about a week of moving into the barn, condensation that formed on the machine each morning caused alot of very light surface rust. It's just that very first stage of rust, orange powder on the surface that can be wiped or brushed away, but it impacts the look as it sits.

I'm interested in any info I can get about what type of parts a machine like this would've made or fixed, and I want to get it to a new owner. Is it really just scrap? Is there more value than that in it to the right person? All I need out of it is the $100 I put in, but if there's more than that in it, I could certainly use it. What can you all tell me?

Thanks, Alex

I work occasionally with a wonderful little machine shop in Pawcatuck CT that's been in business in the same building, with some of the same machinery, for over a century. They're hard working, nice, adaptive guys maintaining a family business whose customer base looks radically different than it did 100 years ago. They needed to add a couple new computer controlled machines, and without a postage stamp of extra real estate in their building, some of the old stuff needed to go. I pulled up one day to find two beautiful old belt driven machines out on the curb. The owners told me that they had tried numerous avenues to find homes for both, even contacting industrial themed bars etc, but had been unsuccessful. The larger one, a surface grinder, had been damaged badly during lifting, but the smaller cylindrical grinder was in good shape. They were headed to the trash, and although I don't know much about the belt drive world, they were too beautiful not to try to save, so I turned my day around, and made a deal with the owner to buy and move the cylindrical grinding machine for scrap value, $100.

I briefly dreamt about using it one day, but it's just not a reasonable thing for me to keep in my life right now. I have so many other projects, work, hobbies, relationships, and very limited resources, not the least of which is storage space. To continue storing this machine in my neighbors barn for the possibility that I might one day set up a belt driven shop and need a cylinder grinder is unreasonable. But I want to find it an owner that can use it, or at least display it properly, and knowledgeably.

Its roughly 4 feet wide and tall, and two deep. It's set up somewhat like a lathe, a sliding deck on top of a tall cabinet, with two movable rotating pointed holders to hold the spinning work, but the tool that comes in to the side of the work is a grinding wheel. I was made by the Brown and Sharpe manufacturing company of Providence RI, and supposedly bought by the shop that sold it to me in 1916. Patent dates cast in range from 1897-1908. It was in good condition when I bought it, with evidence of recent use and respectful maintenance. Things are generally tight and smooth, and seem to all be present, though I really wouldn't know. Unfortunately, within about a week of moving into the barn, condensation that formed on the machine each morning caused alot of very light surface rust. It's just that very first stage of rust, orange powder on the surface that can be wiped or brushed away, but it impacts the look as it sits.

I'm interested in any info I can get about what type of parts a machine like this would've made or fixed, and I want to get it to a new owner. Is it really just scrap? Is there more value than that in it to the right person? All I need out of it is the $100 I put in, but if there's more than that in it, I could certainly use it. What can you all tell me?

Thanks, Alex