I have a B&S Number 5 I bought at auction for my knifemaking shop. The hydraulic start stop lever will not actuate. More specifically, it seems that the pinion that lever should rotate to engage/disengage hydraulic pressure to the rest of the system is seized up solid.

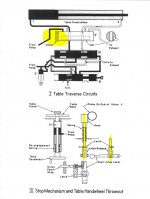

I've attached a diagram of the circuit. With the pump running or not, nothing I do seems to have any effect. Indexing the cross feed latch, changing any of the controls, indexing the table manually, the direction change lever manually, etc. That pinion gear just will not budge. It's stuck way up in there so I cannot really get after it with anything but I did try prying behind the rack while pulling the lever to put some extra force on it, in case it was glued in place by varnish/wax/oil but to no avail.

Any ideas what may cause this? I'm not really set up to remove the table and the saddle, then the valve. I can figure out a way to do it if I have to, and since the access to this valve is so limited that may be my next step, but was hoping someone would have some insight into whether that would be necessary or could be avoided. I'm having a hard time imagining what would seize that pinion up to this extent.

I've attached a diagram of the circuit. With the pump running or not, nothing I do seems to have any effect. Indexing the cross feed latch, changing any of the controls, indexing the table manually, the direction change lever manually, etc. That pinion gear just will not budge. It's stuck way up in there so I cannot really get after it with anything but I did try prying behind the rack while pulling the lever to put some extra force on it, in case it was glued in place by varnish/wax/oil but to no avail.

Any ideas what may cause this? I'm not really set up to remove the table and the saddle, then the valve. I can figure out a way to do it if I have to, and since the access to this valve is so limited that may be my next step, but was hoping someone would have some insight into whether that would be necessary or could be avoided. I'm having a hard time imagining what would seize that pinion up to this extent.