Bob Farr

Cast Iron

- Joined

- Sep 9, 2008

- Location

- Detroit 'burbs

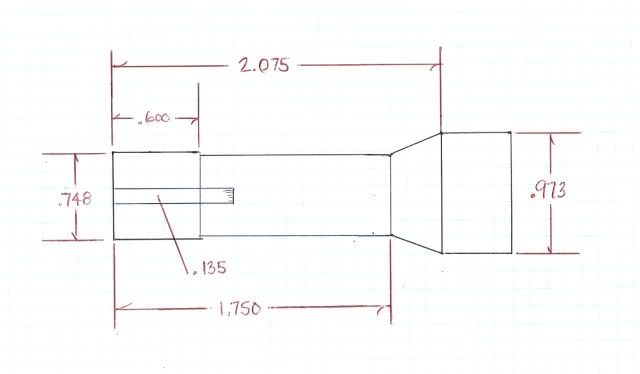

I was very fortunate to acquire this nice little Carter & Hakes horizontal mill yesterday. The table X and knee Z axes are lever fed. The Y axis has a mic dial and a provision for a ball handle (missing). The single T-slot table is 12" long, the X travel is 3", Y travel 3", and Z travel 2". The spindle bore is round with a set screw like an endmill holder, though this may not be the stock configuration.

It's an interesting little machine and a great match for my Sloan & Chace 5-1/2 lathe and Drummond bench shaper. Unfortunately I haven't found much info on the 'Net about it so I'd like to hear from any other owners who can share their experiences and setups.

Thanks,

Bob

It's an interesting little machine and a great match for my Sloan & Chace 5-1/2 lathe and Drummond bench shaper. Unfortunately I haven't found much info on the 'Net about it so I'd like to hear from any other owners who can share their experiences and setups.

Thanks,

Bob

Last edited: