Lester:

You do have a knack for finding (and showing us) some of the most interesting and well made model and small-sized steam plants. My guess is Mr. Baugh built the steam engine as a working model. It was a common thing many years ago for machinists and stationary engineers as well as marine engineers to build model steam engines. An old friend had a model of a steam launch in the window of his auto parts shop in Marquette, Michigan in the 1970's. The launch was about 3 feet long with a working steam plant. It had a single cylinder vertical engine, all made of bronze castings, with a mainframe in keeping with what was in use on the Great Lakes many years ago. It also had a vertical boiler, fully jacketed. I used to enjoy looking at that model, and I was told it had been made by a stationary engineer in the waterworks in Duluth, MN many years earlier. The founder of the auto parts store had come from Duluth, and apparently, the stationary engineer at the waterworks was a friend who passed his model along to him. Same sort of construction, one-off bronze castings, one-off fittings apparently made by the same man who made the rest of the model.

Mr. Baugh may well have been any of several professions, as many years ago stationary and marine engineers were usually fairly accomplished machinists. Mr. Baugh likely made patterns and had them poured in bronze in some local foundry. Making the pattern for the cylinder with cored steam passages was quite an accomplishment in its own right, given the small size of things. Mr. Baugh was following stationary engine practice of the 1860's -1890's, I think. The engine is too nicely made and too well finished to have been used as a "working engine" for something like driving sewing machines (a common use for small "working" steam engines and boilers).

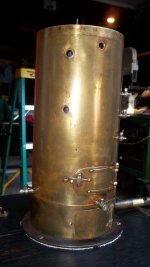

The boiler is a fine piece of work in its own right, and has a "wet" or "submerged" firebox. From the looks of the top ends of the boiler tubes, they were expanded into the sheet. My guess is Mr. Baugh riveted the tubesheets into the boiler barrel, then silver brazed the end of the flanged seam to seal the joint. When that was done, he was comfortable with filing off the rivet heads to flush them with the barrel. We will never know why Mr. Baugh decided to flush off the rivet heads- maybe not to scale, maybe not neat enough to suit his eye. Either way, the boiler is a very fine piece of work. I find myself thinking Mr. Baugh, at the time he build the boiler, may well have done the silver brazing in a charcoal fire. A gasoline blow torch (blow lamp to our UK brethren) might have been used as well. Certainly, whatever Mr. Baugh had available at the time was not the easy propositions we have in the form of oxy-fuel torches with various sizes of tips, or TIG torches. He likely had to get some "spelter" (brazing alloy), maybe filed it to make fine particles of it, and mixed his own flux from borax. Painted this mixture on the seams, then put that part of the boiler into the fire or played the blowtorch on it. Maybe had the balance of the boiler buried in a pail of damp sand to limit heat travel.

He may have made a tapered drift to expand the tubes into the sheets, and flared the ends slightly. Nothing was so easily done as we have it today.

The gauge is interesting, to say the least. I believe I saw one very old steam pressure gauge which used a corrugated diaphragm to work the mechanism. As pressure increased, the diaphragm deflected and worked the movement of the gauge. The gauge on this engine and boiler is quite a fine piece of work, and I have to wonder if it were a one-off job. Making a Bourdon tube which would function properly over the range of pressure to be measured, and fit into a small gauge case may have been something Mr. Baugh was unable to do, so he resorted to a different means of sensing steam pressure. Usually, there is a hairspring in mechanical pressure gauge movements, and I wonder if there is a hairspring that is missing from this gauge. I can imagine at the time Mr. Baugh built this steam plant, he may well have gone to a local watchmaker or horologist and asked him to make and fit a hairspring to his gauge movement. He may also have handed the gauge face off to a local engraver for engraving/etching. Different times when a person could go to local craftsmen for one-off out-of-the-ordinary type jobs, and when local foundries would pour one-off jobs like castings for a steam engine model.

As per your style, you have done another exemplary job of bringing the engine and boiler back to first class condition. Mr. Holly, New Jersey is down in Southern NJ, close to Philadelphia, PA. It is a busy area, suburbia, with people living life at a hyperkinetic pace. Crazy traffic, the usual "homogenized" kind of community that is proliferating our country and taking away the individuality and local flavor. It is hard to imagine Mr. Baugh living in Mt Holly at a time when life was slower and machinists, horologists, foundries and places with steam engines (where Mr. Baugh may well have worked) existed.

When Lester takes on one of these steam plants, he shows a respect for the person who made it, and does not take "the easy way" to get things running again. The result is what I call "museum quality" restorations and repairs. At the rate Lester Bowman is going, he could open a small museum of the collection of small steam plants he has taken on and restored and repaired.