sanderson231

Plastic

- Joined

- Jan 25, 2017

I bought this machine about 10 years ago and finally have enough time to restore it. Retirement is great.

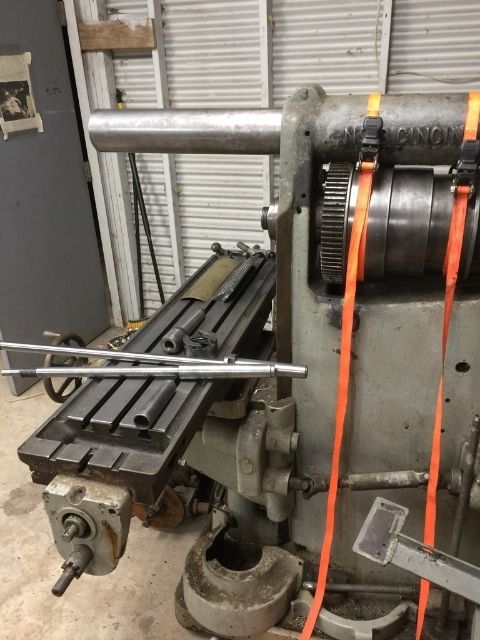

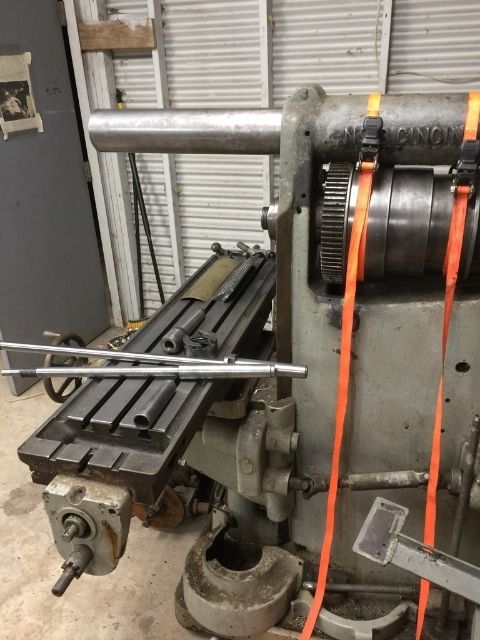

From what I know this machine is from the early 1900's. The spindle is #11 B&S. The nose of the spindle is threaded. There is a slotted collar that screws on spindle that can drive an appropriate arbor. The machine has a two speed back gear. With counter shaft speeds of 145 rpm or 260 rpm and the three step cone pulley, there are 18 spindle speeds ranging from 13 rpm to 350 rpm. The table feed is from a transmission in the bowels of the machine. The transmission is operated by two levers; A or B and C and D as well as a pin with four positions. This gives 16 feed rates ranging from 0.007" to 0.310" per spindle revolution.

Hear are a couple of pictures of the machine:

The problem I am having in disassembling the machine is getting the spindle out. I removed a large set screw from the cone pulley which locked the cone pulley and the two rear back gears to the spindle. The cone and gears now turn freely on the spindle with the spindle held stationary. The spindle turn easily in its bearings. But when I try to pull the spindle out something is preventing it. I suspect it is some type of thrust bearing mechanism that is getting in the way. There are two lock rings on the spindle just ahead of the gear that drive the transmission. I built a hook wrench and was able to get these lock rings free. They are both threaded. Pics of these lock rings below:

The left ring appears to hold the front spindle radial bearing (flanged on front) in place. I suspect the right one is for thrust adjustment. When I try to pull the spindle as shown below then I can no longer rotate this lock ring even though it was hand free before putting an axial force on the spindle.

I believe that the front radial spindle bearing needs to come out so I can get to the thrust mechanism. I tried pushing it out by rotating its lock ring counterclockwise as much as I dared. It wouldn't budge. Soaked it with Kroil and will try again tomorrow.

Anybody have any other thoughts on how to get the spindle out?

From what I know this machine is from the early 1900's. The spindle is #11 B&S. The nose of the spindle is threaded. There is a slotted collar that screws on spindle that can drive an appropriate arbor. The machine has a two speed back gear. With counter shaft speeds of 145 rpm or 260 rpm and the three step cone pulley, there are 18 spindle speeds ranging from 13 rpm to 350 rpm. The table feed is from a transmission in the bowels of the machine. The transmission is operated by two levers; A or B and C and D as well as a pin with four positions. This gives 16 feed rates ranging from 0.007" to 0.310" per spindle revolution.

Hear are a couple of pictures of the machine:

The problem I am having in disassembling the machine is getting the spindle out. I removed a large set screw from the cone pulley which locked the cone pulley and the two rear back gears to the spindle. The cone and gears now turn freely on the spindle with the spindle held stationary. The spindle turn easily in its bearings. But when I try to pull the spindle out something is preventing it. I suspect it is some type of thrust bearing mechanism that is getting in the way. There are two lock rings on the spindle just ahead of the gear that drive the transmission. I built a hook wrench and was able to get these lock rings free. They are both threaded. Pics of these lock rings below:

The left ring appears to hold the front spindle radial bearing (flanged on front) in place. I suspect the right one is for thrust adjustment. When I try to pull the spindle as shown below then I can no longer rotate this lock ring even though it was hand free before putting an axial force on the spindle.

I believe that the front radial spindle bearing needs to come out so I can get to the thrust mechanism. I tried pushing it out by rotating its lock ring counterclockwise as much as I dared. It wouldn't budge. Soaked it with Kroil and will try again tomorrow.

Anybody have any other thoughts on how to get the spindle out?