IrbyJones

Stainless

- Joined

- Jun 9, 2005

- Location

- Poquoson, Va

I know several folks here own an old Garvin universal dividing head like I have -

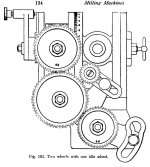

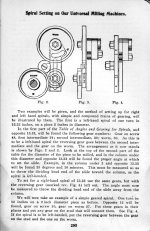

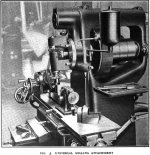

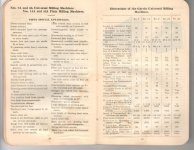

I need to use it to cut a spiral groove in a part, so I need to make a banjo and some gear adapters to drive the dividing head from the table feed screw. I've seen examples of how this is done, but never a closeup of a Garvin dividing head like mine in use. Since I'm going to make up these "accessories", I might as well have them look similar to the originals if possible.

Sooo, does anyone happen to have an original banjo (or whatever they were called) and the adapters that went between the gears and the banjo for this Garvin dividing head - that I can get pictures and dimensions from? Or even a good detailed picture of them from an old ad or book? All I can find in the old catalogs are pictures like these, which don't show details.

Thanks!

Irby

I need to use it to cut a spiral groove in a part, so I need to make a banjo and some gear adapters to drive the dividing head from the table feed screw. I've seen examples of how this is done, but never a closeup of a Garvin dividing head like mine in use. Since I'm going to make up these "accessories", I might as well have them look similar to the originals if possible.

Sooo, does anyone happen to have an original banjo (or whatever they were called) and the adapters that went between the gears and the banjo for this Garvin dividing head - that I can get pictures and dimensions from? Or even a good detailed picture of them from an old ad or book? All I can find in the old catalogs are pictures like these, which don't show details.

Thanks!

Irby