The Hamilton is a very unique lathe. I used one once, and always remembered that "revolver" type of quick change gearing. You have preserved a unique old machine tool, for sure. It looks like it is "plug and play", not outside long enough to wind up heavily rusted, not dropped or damaged with nothing busted, missing, or brazed back together. Good luck with that lathe !

Joe in NH:

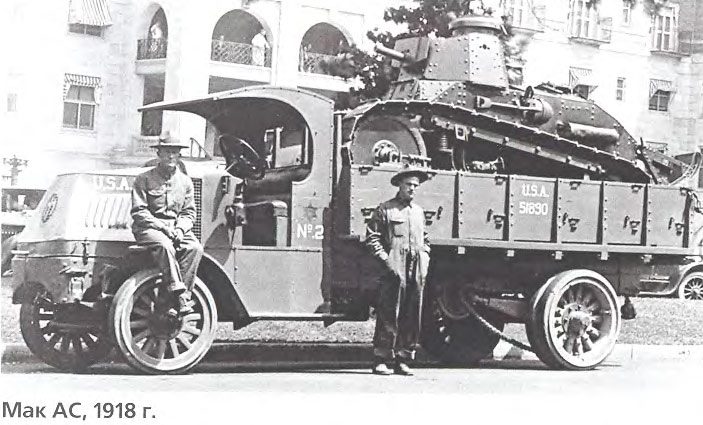

No disrespect: the Mack you have pictured is one of the lighter models, and post WWI if I am not mistaken. It has been retrofitted with pneumatic tires, so probably was in use way longer than most trucks these days. The "bell shaped" grayish area on the side of the half cab has the original Mack builder's plate. It included a picture of a fierce British Bulldog chewing up a book. Somewhere on that engraving were the words "competitor's specifications".

The truck that first earned the name "Bulldog" and made Mack's name in WWI was the old AC model. This truck had a sloped hood, and had the radiator set in the cowling, between the driver and the engine. The AC series were much heavier duty trucks, and came out of the factory with solid rubber tires. They were used in large numbers by the Allied forces in WWI. Supposedly, the fact that the hood sloped down and the truck had a kind of "heavy stance" to it and kept slogging along in mud and all else led the British soldiers to refer to them as "bulldogs".

A machinery mover would use an AC series Mack, but he'd have a "beavertail" or down-slope on the tail of the bed. Mounted just abaft of the cab would be a PTO driven capstan type of winch. Using hemp rope snubbed around the capstan, along with rollers, hardwood planks, wood blocking and hardwood low horses, the oldtime machinery movers would pull machine tools up onto the truck bed. Using "track jacks" (ratchet type mechanical jacks) if a machine was too heavy to raise with pinch bars, the oldtime machinery movers would first get the machine tool onto skid timbers. The old master riggers and machinery movers would accomplish some amazing feats with very simple means and an old Bulldog Mack with a capstan winch. As a kid and young man, I saw the oldtime machinery movers in NYC using trucks that were then at least 25 years old. Those guys could waltz a machine tool, safe, printing press or baby grand piano in or out of the tightest of places.

I think we are a bit spoiled nowadays, having the wonderful inventions of hydraulics, torque converters, automatic transmissions, and similar to make moving a machine tool a lot easier. The oldtimers who drove those Bulldog Macks with the "half cabs" could not imagine loading a machine tool on a modern tilt bed truck, using easily operated hydraulics. They'd be thinking they went to heaven, sitting in a quiet modern truck cab with cushy seat, power assisted braking (or airbrakes), heat or air conditioning, and at least a synchromesh transmission if not an automatic. Add power steering and a "self starter", and those guys would think they were on a joyride of rest cure. The old Hamilton lathe probably was shipped via rail from the Hamilton plant, on trains drawn by steam locomotives. Maybe it arrived at the original owner's plant on the owner's rail siding. Maybe the owner got the word the lathe was taken off a boxcar at the railhead and was sitting awaiting pickup. That is when the lathe might have taken its ride on the Bulldog Mack, or maybe even a horse-drawn dray.

The men who designed and built that lathe and the company they worked for have long passed from this life. The trains and that way of life are gone as well as the old Bulldog Macks. The Hamilton Lathe is the survivor. It has survived quite well, and will likely give another hundred or so years of good service with anything like reasonable care.