TySym1

Plastic

- Joined

- Jan 15, 2019

- Location

- Mighty Midwest

Hello All

So, I think I can go load up my very first lathe tomorrow if things go well!

Problem is just that though; I've never owned one. So far I've done Hours of reading, especially starting a few years back when I first got interested in the idea that I just couldn't shake. Also grew up around manufacturing in a small-medium business setting, so that helps(or might be the problem ha)

ha)

Anyhow,

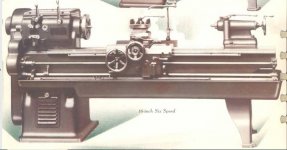

the Lathe is a LeBlond.

Claims simply "8x20" which I couldn't find anything matching so I am REALLY hoping someone here could help me gain some info on this machine.

It Looks like something I can actually grow Into, rather than be stuck on something from limitations and have to upgrade. Very comfortable with it being too big of a first bite if that's the case, also.

Real dead set on this working iron; it's been a long time commin'.

I will try to figure out how to post the VERY limited pictures I have.

Would Love to finally get into the hobby!

So, I think I can go load up my very first lathe tomorrow if things go well!

Problem is just that though; I've never owned one. So far I've done Hours of reading, especially starting a few years back when I first got interested in the idea that I just couldn't shake. Also grew up around manufacturing in a small-medium business setting, so that helps(or might be the problem

ha)

ha)Anyhow,

the Lathe is a LeBlond.

Claims simply "8x20" which I couldn't find anything matching so I am REALLY hoping someone here could help me gain some info on this machine.

It Looks like something I can actually grow Into, rather than be stuck on something from limitations and have to upgrade. Very comfortable with it being too big of a first bite if that's the case, also.

Real dead set on this working iron; it's been a long time commin'.

I will try to figure out how to post the VERY limited pictures I have.

Would Love to finally get into the hobby!