How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hendey 14x5

- Thread starter KentStuff

- Start date

- Replies 13

- Views 1,855

johnoder

Diamond

- Joined

- Jul 16, 2004

- Location

- Houston, TX USA

M.B. Naegle

Diamond

- Joined

- Feb 7, 2011

- Location

- Conroe, TX USA

Did some cleaning last night. Everything is fairly free now. The head is still stiff. It will turn with back gear engaged but very stiff straight run. Here are a few close ups of the bed.

View attachment 267381View attachment 267382

Interesting piece behind the cross-slide. I'm guessing it's part of a follow rest since it's not attached to the cross-slide? I've seen some like that home-made, not an original cast iron one.

johnoder

Diamond

- Joined

- Jul 16, 2004

- Location

- Houston, TX USA

Has the usual Hendey issue of front bearing of spindle dragging /binding in its tapered bore

Lots of threads on this forum addressing same

Not an adjustment issue - its a take apart and fix situation. In the process you get to learn about and appreciate Hendey's magnificent oiling system for the spindle bearings

Lots of threads on this forum addressing same

Not an adjustment issue - its a take apart and fix situation. In the process you get to learn about and appreciate Hendey's magnificent oiling system for the spindle bearings

Did some cleaning last night. Everything is fairly free now. The head is still stiff. It will turn with back gear engaged but very stiff straight run. Here are a few close ups of the bed.

Interesting piece behind the cross-slide. I'm guessing it's part of a follow rest since it's not attached to the cross-slide? I've seen some like that home-made, not an original cast iron one.

When I bought the lathe 20 years ago, it came with 4 or 5 boxes of stuff. I bought a milling machine and this in a package deal. The old man wanted to get rid of it so his family would not fight over it. He just started boxing everything up that looked like it went with it. This was in one of the boxes. I had no idea what most of the things were when I brought it home. It was all in good working order at that time. Life, kids, and job found themselves in front of the lathe, (which it should be.) But not good for the lathe. Anyway, going through the boxes last night, I found it and determined that it was a follower and that it mounted here. Both holes line up and it is dead center as it sits. It needs some cleaning and another bolt. But yes, it is a factory cast, almost with that same blue-green paint. Not sure if it is original.

Has the usual Hendey issue of front bearing of spindle dragging /binding in its tapered bore

Lots of threads on this forum addressing same

Not an adjustment issue - its a take apart and fix situation. In the process you get to learn about and appreciate Hendey's magnificent oiling system for the spindle bearings

After reading some of the other post, I was afraid of that. Thanks for the other information as well.

johnoder

Diamond

- Joined

- Jul 16, 2004

- Location

- Houston, TX USA

After reading some of the other post, I was afraid of that. Thanks for the other information as well.

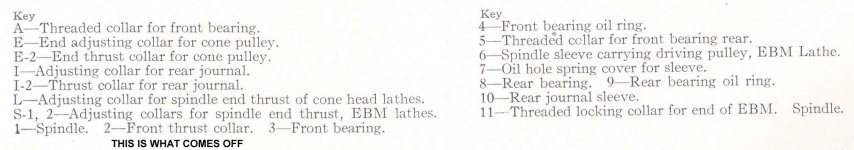

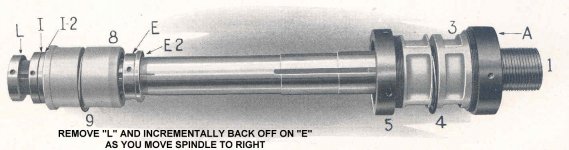

Here is the usual handy related info, though it is probably on most of the other related threads

Attachments

johnoder

Diamond

- Joined

- Jul 16, 2004

- Location

- Houston, TX USA

Thanks for the info. Handy right here. Do you know if anything has reverse threads? I hate to start trying to take something off and it is threaded backwards.

Pretty ordinary - all right hand if I recall correctly. The "gotchas" are the unnoticed set screws locking the threaded ring nuts in place.

.

.You have to have those LOOSE.

Hendey originally had brass or bronze (or even Babbitt) "pads" under the set screws to avoid ruining threads - but you never know after 100 years. Bubba may have lost such things

I oiled all the tapered bearings and let them soak for a week. I went by about every other day and added more PB Blaster. The spindle began to free up a little at a time. I would engage the back gear and turn it by hand several rounds. It got a little better and each day was easier to turn. Yesterday, after studying all the inter-workings of the spindle, I figured that a few taps with a block of wood on the rear of the spindle would not hurt anything. Sure enough, it got free enough that I though that I could turn it on in the lowest belt drive. It ran fairly smooth. I checked it for heat or any type of weird grinding and found none. After running for 20 minutes or so, it is fairly free again in the back gear. I'm able to run all of the apron and change into each of the gears. After sitting all night, started it again this morning and decided it was free enough to try the straight gear. Sure enough it will turn and getting better. Washing out the taper bearings with new oil, it is getting much better. At this point, I don't think that I'm going to attempt to pull the head apart. After all, 16 years ago it was shut off running smooth. Maybe, just the old oil/grease just needs to be washed out or warmed up by running it.

Looking into the oil holes, the bearing and oil rings look very good. No signs of rust at all. I'm curious how stiff it should be by hand in straight run without any of the apron engaged? I would not call it free, but it is no problem to turn by hand. Any thoughts??

Looking into the oil holes, the bearing and oil rings look very good. No signs of rust at all. I'm curious how stiff it should be by hand in straight run without any of the apron engaged? I would not call it free, but it is no problem to turn by hand. Any thoughts??

johnoder

Diamond

- Joined

- Jul 16, 2004

- Location

- Houston, TX USA

The acid test will be loading it up from the tail stock end - like drilling a fair size hole in steel. If it suddenly gets worse its an indication that you are shoving the tapered journal into the tapered bearing and it is starting to bind/drag.

Bopping the back end will free it up - but only until you want the lathe to do some work again

Bopping the back end will free it up - but only until you want the lathe to do some work again

M.B. Naegle

Diamond

- Joined

- Feb 7, 2011

- Location

- Conroe, TX USA

Cleaning out the old lubricant will be a big help. Shimming the spindle is done to correct wear in the bearings, but figuring that out can be thrown off by whatever crud is in there. Once you have the machine functional, keep an eye on the bearing temperatures, but also see if cutting towards or away from the spindle changes things (bogging down or bearings getting hot).

Similar threads

- Replies

- 9

- Views

- 487

- Replies

- 20

- Views

- 1K

- Replies

- 12

- Views

- 726