Dr. Hillbilly

Aluminum

- Joined

- Dec 6, 2019

- Location

- Oregonia, Ohio

I drug my Hendey home from MN. Now the works starts...

I call this "phase 1" because it will be the longest lasting phase so I need to start working on it first. I can do the easy stuff in parallel.

My Universal is missing its indexing table. Does anyone know of a Hendey index table available? I fear not, so I assume this phase comprises the modification of some other table for use.

I want to be able to cut worm and helical gears, so I need the following attachments:

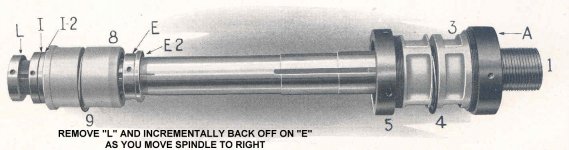

Images are courtesy of the Torrington Historical Society (they gave me permission to post them)

I have been following the recent posts for the Cincinnati No. 2 addressing a parallel subject. So I need to source a table and build a gear plate with an adjustable link, and angle plates to orient the centerline of the table in the Y-Z plane, the X-Y plane, or the X-Z plane.

Any templates, drawings, suggestions, or warnings are welcome.

I call this "phase 1" because it will be the longest lasting phase so I need to start working on it first. I can do the easy stuff in parallel.

My Universal is missing its indexing table. Does anyone know of a Hendey index table available? I fear not, so I assume this phase comprises the modification of some other table for use.

I want to be able to cut worm and helical gears, so I need the following attachments:

Images are courtesy of the Torrington Historical Society (they gave me permission to post them)

I have been following the recent posts for the Cincinnati No. 2 addressing a parallel subject. So I need to source a table and build a gear plate with an adjustable link, and angle plates to orient the centerline of the table in the Y-Z plane, the X-Y plane, or the X-Z plane.

Any templates, drawings, suggestions, or warnings are welcome.