Asquith

Diamond

- Joined

- Mar 3, 2005

- Location

- Somerset, UK

A handful of machines have survived in the UK which represent great leaps forward in machine tool technology.

One is the 200-year old Richard Roberts lathe in the London Science Museum.

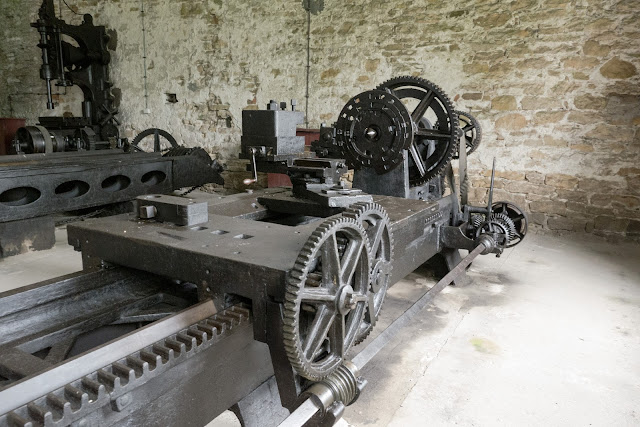

Here’s another, in more representative surroundings, made by James Fox of Derby. Date: Believed to be c.1820, give or take a few years.

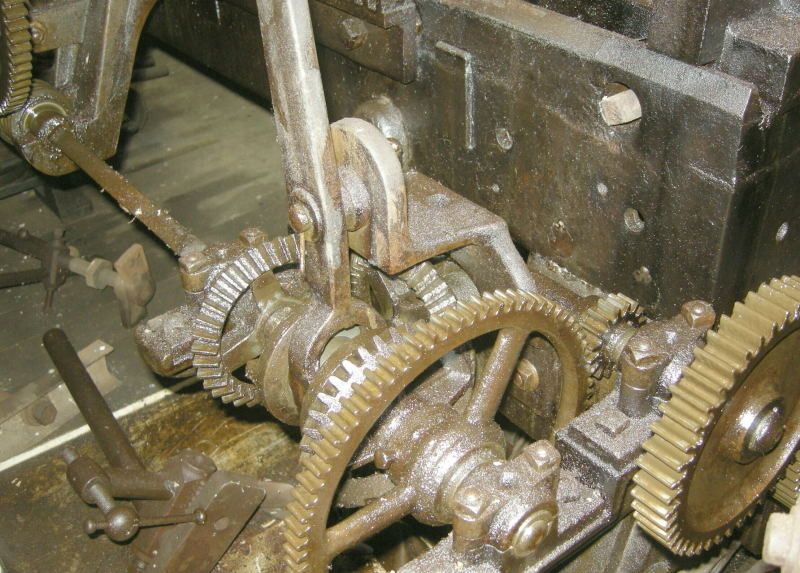

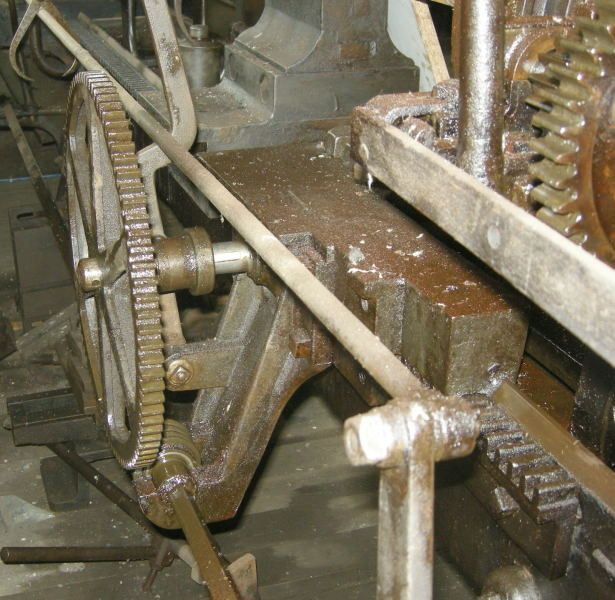

All-metal construction, box bed with V and flat ways, back-geared, screw cutting, clasp nut, powered carriage traverse with automatic feed cut-off. Tailstock can be set over. Tapered spindle bearings. Compound swivelling slide. Rack and pinion travel for carriage and tailstock. All the things we now take for granted, but very advanced compared with the typical lathes of this period.

I’ll say more about the history of this lathe later, when I’m hoping that 'Millwright' will help me out.

The lathe is on display - and workable via a lineshaft - at an outstanding industrial museum in South Yorkshire - Wortley Top Forge. I’ll aim to say much more about this site in other threads. Link to website:-

http://www.topforge.co.uk/

For my visit I had the great pleasure of Millwright’s company, and as an added bonus he’d arranged for us to get together with Ken Hawley, a remarkable man who’s made a vital contribution to saving historical industrial artefacts in the region, and to the establishment of Wortley Top Forge Museum.

One is the 200-year old Richard Roberts lathe in the London Science Museum.

Here’s another, in more representative surroundings, made by James Fox of Derby. Date: Believed to be c.1820, give or take a few years.

All-metal construction, box bed with V and flat ways, back-geared, screw cutting, clasp nut, powered carriage traverse with automatic feed cut-off. Tailstock can be set over. Tapered spindle bearings. Compound swivelling slide. Rack and pinion travel for carriage and tailstock. All the things we now take for granted, but very advanced compared with the typical lathes of this period.

I’ll say more about the history of this lathe later, when I’m hoping that 'Millwright' will help me out.

The lathe is on display - and workable via a lineshaft - at an outstanding industrial museum in South Yorkshire - Wortley Top Forge. I’ll aim to say much more about this site in other threads. Link to website:-

http://www.topforge.co.uk/

For my visit I had the great pleasure of Millwright’s company, and as an added bonus he’d arranged for us to get together with Ken Hawley, a remarkable man who’s made a vital contribution to saving historical industrial artefacts in the region, and to the establishment of Wortley Top Forge Museum.

Last edited: