Asquith

Diamond

- Joined

- Mar 3, 2005

- Location

- Somerset, UK

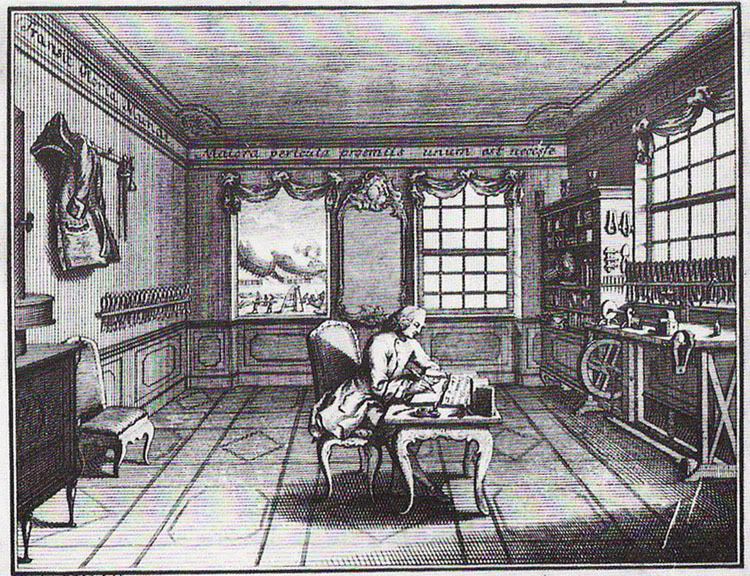

In this thread I would like to focus on lathes used for industrial metal turning in the late 18th to early 19th century.

Georgian metal-turning lathes, for want of a better term.

Another description might be prehistoric, as little seems to have been recorded about the ordinary industrial lathes of that period.

Gentlemen's lathe, such as those made by Holtzapffel, are well documented. We also know quite a lot about early precision lathes, such as those produced by Maudslay and Vaucanson, and about the great leap forward in lathe design brought about by the likes of Richard Roberts, Joseph Clements, and James Fox c.1820.

I’ll be posting pictures of early lathes of unknown date, and an energetic discussion will ensue, bringing all sorts of vital information out of the closet. Hmmm.

For some of these lathes I'll claim that they may date from the late 1700s or very early 1800s, with no supporting evidence, and little more than a feeling that the detail design and crudeness of the castings is consistent with that era.

Some will look at the photos and say 'No way that those lathes are from that era'. My response will be to accept that I don’t know, and to ask the question: What, then, did ordinary industrial lathes look like at that time?

For there must have been many, and they certainly weren't made of wood, so where have they all gone? The period of interest is the Industrial Revolution, when there was an explosion in demand for turned metal components. Large quantities of small-medium sized components were needed (for cotton spinning machinery, for example) from the 1770s onward. Large turned iron components were needed for waterwheels, lineshafts, steam engines, etc. Where are the lathes used to turn these items, if not some of those to appear in the following photos?

The lathes to be featured will have headstocks and tailstocks and tool rests made from iron and steel, and will often have wooden beds. They would serve either for wood or metal turning.

I will not be focusing on triangular bed lathes, as they have been well-covered elsewhere (e.g. thread link below) and they mostly appear to have a narrow field of application (Maudslay and gentlemen turners).

http://www.practicalmachinist.com/vb/antique-machinery-history/triangular-bed-lathe-ebay-204315/

Georgian metal-turning lathes, for want of a better term.

Another description might be prehistoric, as little seems to have been recorded about the ordinary industrial lathes of that period.

Gentlemen's lathe, such as those made by Holtzapffel, are well documented. We also know quite a lot about early precision lathes, such as those produced by Maudslay and Vaucanson, and about the great leap forward in lathe design brought about by the likes of Richard Roberts, Joseph Clements, and James Fox c.1820.

I’ll be posting pictures of early lathes of unknown date, and an energetic discussion will ensue, bringing all sorts of vital information out of the closet. Hmmm.

For some of these lathes I'll claim that they may date from the late 1700s or very early 1800s, with no supporting evidence, and little more than a feeling that the detail design and crudeness of the castings is consistent with that era.

Some will look at the photos and say 'No way that those lathes are from that era'. My response will be to accept that I don’t know, and to ask the question: What, then, did ordinary industrial lathes look like at that time?

For there must have been many, and they certainly weren't made of wood, so where have they all gone? The period of interest is the Industrial Revolution, when there was an explosion in demand for turned metal components. Large quantities of small-medium sized components were needed (for cotton spinning machinery, for example) from the 1770s onward. Large turned iron components were needed for waterwheels, lineshafts, steam engines, etc. Where are the lathes used to turn these items, if not some of those to appear in the following photos?

The lathes to be featured will have headstocks and tailstocks and tool rests made from iron and steel, and will often have wooden beds. They would serve either for wood or metal turning.

I will not be focusing on triangular bed lathes, as they have been well-covered elsewhere (e.g. thread link below) and they mostly appear to have a narrow field of application (Maudslay and gentlemen turners).

http://www.practicalmachinist.com/vb/antique-machinery-history/triangular-bed-lathe-ebay-204315/