elieberman

Plastic

- Joined

- Aug 6, 2019

Hello,

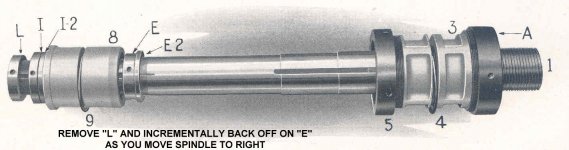

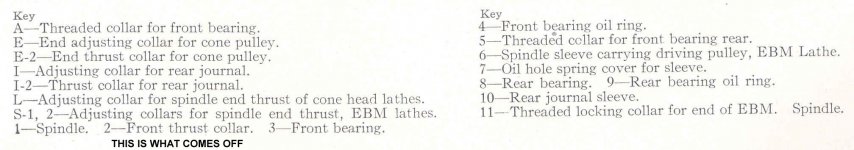

After a 2 year process of acquiring and moving I now have in my shop a 12X4 Hendey. For something this old it is in good condition and still has most of the parts. Everything is working well except for the main spindle gets stuck. I have removed it and am making a shim for behind the oil seal.

The serial number on the bed is 15308. The son of the last owner said the gentleman worked for Winchester Firearms in New Haven and may have gotten it from them. It does have a tag saying it was sold by the Botwink Bros. ( Used machinery dealer ? )

I grew up in Litchfield CT and know the area in Torrington where this lathe was made. Part of it is now where the Stop & Shop is. After reading the Hendey history I recognized some of the last names as people who still lived in the area.

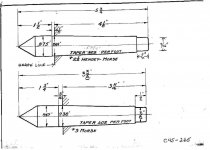

I would appreciate any additional information. One item I am concerned about is the tailstock taper. I think it might be a Jarno taper. Has anyone reamed this to a Morris #3 ?

Thanks in advance,

Eric

After a 2 year process of acquiring and moving I now have in my shop a 12X4 Hendey. For something this old it is in good condition and still has most of the parts. Everything is working well except for the main spindle gets stuck. I have removed it and am making a shim for behind the oil seal.

The serial number on the bed is 15308. The son of the last owner said the gentleman worked for Winchester Firearms in New Haven and may have gotten it from them. It does have a tag saying it was sold by the Botwink Bros. ( Used machinery dealer ? )

I grew up in Litchfield CT and know the area in Torrington where this lathe was made. Part of it is now where the Stop & Shop is. After reading the Hendey history I recognized some of the last names as people who still lived in the area.

I would appreciate any additional information. One item I am concerned about is the tailstock taper. I think it might be a Jarno taper. Has anyone reamed this to a Morris #3 ?

Thanks in advance,

Eric