Joe Michaels

Diamond

- Joined

- Apr 3, 2004

- Location

- Shandaken, NY, USA

Last week, my buddy & I drove up to Oswego, NY and picked up the K.O. Lee tool and cutter grinder I had bought from member Marka. Marka has an amazing shop with a lineup of classic US machine tools, all 'heavy hitters'. The building itself is a classic with 'monitor' or 'clerestory' roof line. Between Covid-19 and miles yet to be turned, we did not have a lengthy visit, but were happy to meet Marka and see his shop. He loaded the K.O. Lee tool and cutter grinder with a brand-spanking-new Kubota tractor/loader and we soon were on our way home again.

The total day's events amounted to 12 1/2 hours. I offloaded the grinder and its base with my own tractor. I have to hand it to K.O. Lee: they did not skimp on the cabinet base for the grinder. It is a massive iron casting. The only part of it which is sheet metal is the cabinet door.

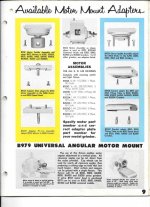

The K.O. Lee grinder is an older model (possibly a 360) from what I can tell, the smallest T & C grinder in K.O. Lee's lineup. The grinder came with a load of flat belt pulleys to drive the grinder spindle. From what I got from an online K.O. Lee manual, the spindle is a B 6055 B. This has a fairly small female grinder taper at one end, and a plain 5/8" threaded arbor at the other.

There is a fairly small diameter steel flat belt pulley on the 5/8" arbor end of the spindle, with enough of the 5/8" spindle/threads projecting to mount grinding wheels. The other end of the spindle has a flange that is approximately flush with the outer circumference of the quill. There is a very small vee groove in this flange, which seems like it would be a vee belt sheave integral with the spindle.

The grinder came with quite a number of flat belt pulleys, and two belt guards. No vee belt pulley for the motor was with the grinder.

My question is: what profile of vee belt is used on these grinders & where can I purchase them ? For whatever reaso n, this grinder came with quite a number of different sized flat belt pulleys. The combinations of flat belt pulleys should give me spindle speeds sufficient for most sizes of wheels and mounted grinding points. Nevertheless, the K.O. Lee manual I found online makes no mention of flat belt spindle drives, only the vee belts. Could the flat belt drives mean this is a fairly old grinder ? Sopko has the replacement flat belts, so no problem in that department.

As for the vee belt drive: I can machine an aluminum vee belt sheave for the motor & static balance it. Along these same lines: Sopko does not appear to offer small arbors with the male 'standard grinder taper' (3 inches/foot). If anyone has any of these small arbors to sell, please let me know. If not, I will make those arbors as the need arises. Having the motorized work head, I can finish grind the taper and straight portions of the arbors, a nice little exercise.

The grinder came with an arbor having a 1/4" collet on a tapered male shank. That was it for arbors. I did check with Wm Sopko, and they offer adapters for the 5/8" plain arbors to mount various grinding wheels. No sense re-inventing the wheel (sorry about the pun), so I will contact Sopko for the wheel adapters.

I got a motorized workhead, along with a dead center/drive pulley for it, and a 4 jaw chuck. The workhead spindle came with a 5C collet closer, so I am all set and quite pleased with what I got. There is also a tailstock along with an assortment of wheel guards with the grinder, and a variety of odds-and-ends.

The female taper end of the spindle is evidently meant to run much smaller diameter wheels or mounted grinding 'points', so the vee belt drive seems the likely means to get up to higher spindle speeds.

Tooling needed for the grinder:

- 'universal' workhead (not sure if this is the correct name for it), preferably taking the 5C collets, for holding end mills and similar. If anyone has one of these workheads, preferably a smaller one to sell, I'd appreciate hearing about it.

-'finger' to run in flutes of cutters and reamers (plenty of micrometer adjustable fingers on ebay as used items, no problem to make a mounting for them).

Another buddy gave me a birthday present of a Weldon end mill sharpening fixture (for grinding the cutting edges and relief angles on the sides of the end mills). This needs the 'finger' as well.

This K.O. Lee grinder is not much bigger than an automotive valve grinding machine (or so it seems to me). It is just the right size for my shop. Some cleaning-up and checking of table way lubrication (have not had the table off as yet), and a 3-phase power converter and I should be ready to start playing with it. I am quite pleased with the grinder, as it is a basic tool and cutter grinder, with the bonus of the motorized work head.

Thanks again to member Marka for holding the grinder until I could get up to Oswego and to my buddy Robert who made the run with me.

The total day's events amounted to 12 1/2 hours. I offloaded the grinder and its base with my own tractor. I have to hand it to K.O. Lee: they did not skimp on the cabinet base for the grinder. It is a massive iron casting. The only part of it which is sheet metal is the cabinet door.

The K.O. Lee grinder is an older model (possibly a 360) from what I can tell, the smallest T & C grinder in K.O. Lee's lineup. The grinder came with a load of flat belt pulleys to drive the grinder spindle. From what I got from an online K.O. Lee manual, the spindle is a B 6055 B. This has a fairly small female grinder taper at one end, and a plain 5/8" threaded arbor at the other.

There is a fairly small diameter steel flat belt pulley on the 5/8" arbor end of the spindle, with enough of the 5/8" spindle/threads projecting to mount grinding wheels. The other end of the spindle has a flange that is approximately flush with the outer circumference of the quill. There is a very small vee groove in this flange, which seems like it would be a vee belt sheave integral with the spindle.

The grinder came with quite a number of flat belt pulleys, and two belt guards. No vee belt pulley for the motor was with the grinder.

My question is: what profile of vee belt is used on these grinders & where can I purchase them ? For whatever reaso n, this grinder came with quite a number of different sized flat belt pulleys. The combinations of flat belt pulleys should give me spindle speeds sufficient for most sizes of wheels and mounted grinding points. Nevertheless, the K.O. Lee manual I found online makes no mention of flat belt spindle drives, only the vee belts. Could the flat belt drives mean this is a fairly old grinder ? Sopko has the replacement flat belts, so no problem in that department.

As for the vee belt drive: I can machine an aluminum vee belt sheave for the motor & static balance it. Along these same lines: Sopko does not appear to offer small arbors with the male 'standard grinder taper' (3 inches/foot). If anyone has any of these small arbors to sell, please let me know. If not, I will make those arbors as the need arises. Having the motorized work head, I can finish grind the taper and straight portions of the arbors, a nice little exercise.

The grinder came with an arbor having a 1/4" collet on a tapered male shank. That was it for arbors. I did check with Wm Sopko, and they offer adapters for the 5/8" plain arbors to mount various grinding wheels. No sense re-inventing the wheel (sorry about the pun), so I will contact Sopko for the wheel adapters.

I got a motorized workhead, along with a dead center/drive pulley for it, and a 4 jaw chuck. The workhead spindle came with a 5C collet closer, so I am all set and quite pleased with what I got. There is also a tailstock along with an assortment of wheel guards with the grinder, and a variety of odds-and-ends.

The female taper end of the spindle is evidently meant to run much smaller diameter wheels or mounted grinding 'points', so the vee belt drive seems the likely means to get up to higher spindle speeds.

Tooling needed for the grinder:

- 'universal' workhead (not sure if this is the correct name for it), preferably taking the 5C collets, for holding end mills and similar. If anyone has one of these workheads, preferably a smaller one to sell, I'd appreciate hearing about it.

-'finger' to run in flutes of cutters and reamers (plenty of micrometer adjustable fingers on ebay as used items, no problem to make a mounting for them).

Another buddy gave me a birthday present of a Weldon end mill sharpening fixture (for grinding the cutting edges and relief angles on the sides of the end mills). This needs the 'finger' as well.

This K.O. Lee grinder is not much bigger than an automotive valve grinding machine (or so it seems to me). It is just the right size for my shop. Some cleaning-up and checking of table way lubrication (have not had the table off as yet), and a 3-phase power converter and I should be ready to start playing with it. I am quite pleased with the grinder, as it is a basic tool and cutter grinder, with the bonus of the motorized work head.

Thanks again to member Marka for holding the grinder until I could get up to Oswego and to my buddy Robert who made the run with me.