hlr270

Plastic

- Joined

- Dec 25, 2008

- Location

- Northeast Georgia

Hello, I'm new to this forum and did a quick search and did not find anything related to my questions regarding my lathe.

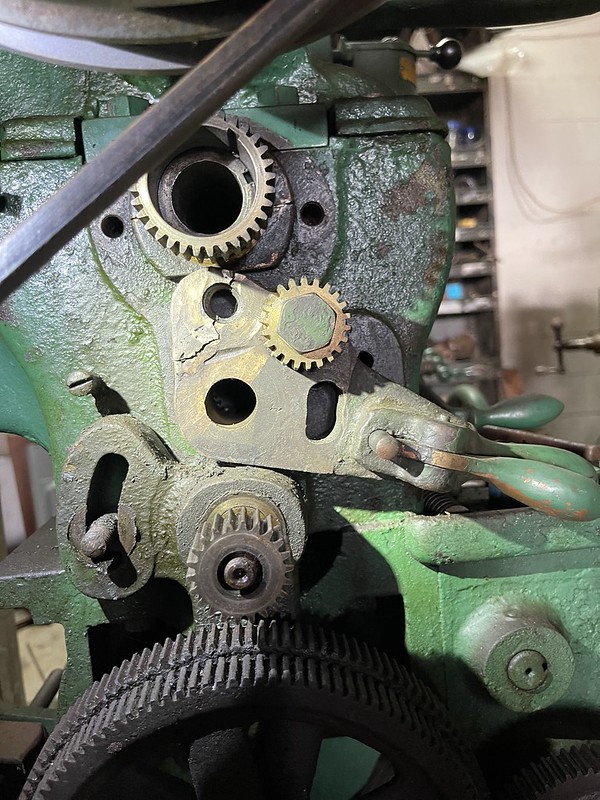

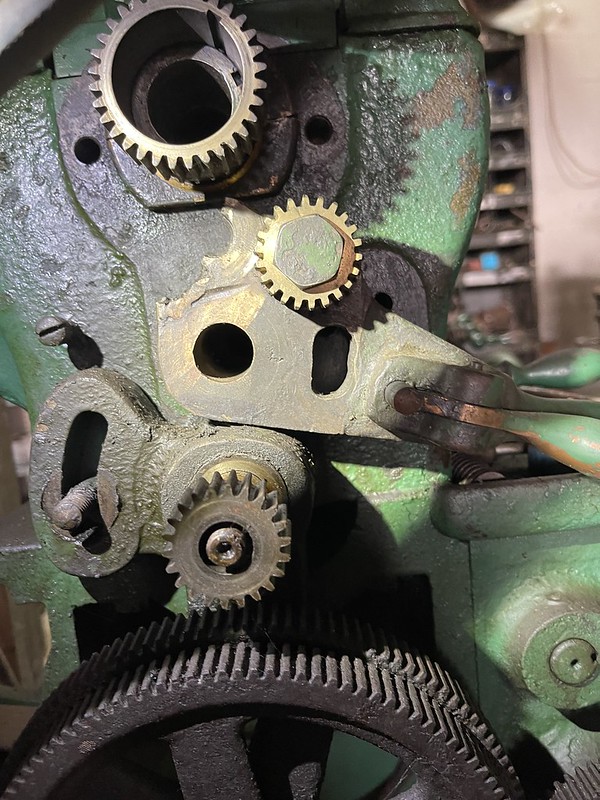

What Iknow about this lathe is simply that it is a Davis Machine Tool Co. 12" X 36" metel lathe. It has a plaque that says "Liberty Lathe Designed for U.S.A." on the front of the gear box. The original motor has been gutted and a second motor has been added. It drives the the lathe through a shaft via V-belt which in turn drives a chain drive up to the gearbox. Everything functions though I have not turned anything on it yet so I do not know how accurate it is. The bed show wear near the chuck end but are in good or better condition further along them. If anyone here has any information about this type of lathe or the Davis Tool Co. I would be very happy to learn more about both. Sorry about the big pictures I'll figure out how to do thumbnails ASAP.

What Iknow about this lathe is simply that it is a Davis Machine Tool Co. 12" X 36" metel lathe. It has a plaque that says "Liberty Lathe Designed for U.S.A." on the front of the gear box. The original motor has been gutted and a second motor has been added. It drives the the lathe through a shaft via V-belt which in turn drives a chain drive up to the gearbox. Everything functions though I have not turned anything on it yet so I do not know how accurate it is. The bed show wear near the chuck end but are in good or better condition further along them. If anyone here has any information about this type of lathe or the Davis Tool Co. I would be very happy to learn more about both. Sorry about the big pictures I'll figure out how to do thumbnails ASAP.