jchealey

Plastic

- Joined

- Jan 9, 2012

- Location

- Sacramento (Loomis)

I have a LeBlond Regal lathe that has a serial number of C8714. trying to figure out about what year that is.

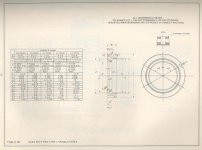

I am going to need a new 3 chuck and an adaptor to a faceplate. It has a 00 taper . I read on here that people are still making adaptors for this lathe but I have not connected yet. Any hints on who?

thanks

Jerry

I am going to need a new 3 chuck and an adaptor to a faceplate. It has a 00 taper . I read on here that people are still making adaptors for this lathe but I have not connected yet. Any hints on who?

thanks

Jerry