Asquith

Diamond

- Joined

- Mar 3, 2005

- Location

- Somerset, UK

Some photos from Laurence, Scott & Electromotors archives. Laurence Scott are still in business in Norwich, England. They used to have a factory in Manchester as well, originally Electromotors, but this closed in 1980s.

http://www.norfolkancestors.org/lsepics/manchester/txn/4.jpg

http://www.lselink.co.uk/images/lsepics/78.jpg

Two photos showing a pair of Ormerod shapers with a radial arm drill between them, for machining the feet of electric motors.

http://www.norfolkancestors.org/lsepics/manchester/txn/2.jpg

Churchill grinder, arranged like a horizontal borer. Note ‘War Finish’ stencilled on the machine.

http://www.lselink.co.uk/images/lsepics/5.jpg

SIP Jig borer

http://www.lselink.co.uk/images/lsepics/23.jpg

Wooden pattern

http://www.lselink.co.uk/images/lsepics/30.jpg

horiz borer

http://www.lselink.co.uk/images/lsepics/168.jpg

Special lathe

http://www.lselink.co.uk/images/lsepics/188.jpg

Dies

http://www.lselink.co.uk/images/lsepics/206.jpg

Asquith radial arm drill

http://www.lselink.co.uk/images/lsepics/212.jpg

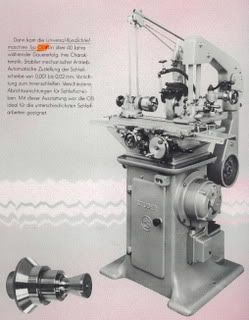

Small grinder

http://www.lselink.co.uk/images/lsepics/219.jpg

Plano miller

http://www.lselink.co.uk/images/lsepics/226.jpg

Churchill cylindrical grinder

http://www.lselink.co.uk/images/lsepics/579.jpg

Grinder

http://www.lselink.co.uk/images/lsepics/232.jpg

http://www.lselink.co.uk/images/lsepics/261.jpg

Noble & Lund lathe

http://www.lselink.co.uk/images/lsepics/243.jpg

http://www.lselink.co.uk/images/lsepics/777.jpg

Craven VBM

http://www.lselink.co.uk/images/lsepics/427.jpg

Modeller

http://www.lselink.co.uk/images/lsepics/550.jpg

Sykes gear hobber

http://www.lselink.co.uk/images/lsepics/560.jpg

Webster & Bennett VBMs

http://www.lselink.co.uk/images/lsepics/581.jpg

Kendall & Gent miller

http://www.lselink.co.uk/images/lsepics/582.jpg

Parkson miller

http://www.lselink.co.uk/images/lsepics/583.jpg

http://www.lselink.co.uk/images/lsepics/584.jpg

Butler slotter

http://www.lselink.co.uk/images/lsepics/596.jpg

http://www.lselink.co.uk/images/lsepics/754.jpg

Butler planer

http://www.lselink.co.uk/images/lsepics/620.jpg

Craven planer

http://www.lselink.co.uk/images/lsepics/613.jpg

Long ago

http://www.lselink.co.uk/images/lsepics/636.jpg

Munition girls

http://www.lselink.co.uk/images/lsepics/789.jpg

Ship’s shaft(?) on Kearns horizontal borer. Jig fitted to coupling for boring bolt holes.

The photos above are from:-

http://www.norfolkancestors.org/lse/lsegallery.php

…and so far I’ve only scratched the surface!

Some more here, which I’ve only had a quick glance at ……

http://www.norfolkancestors.org/lse/laurenceintro.htm

An example…..

Small gear inspection

I’m very grateful to the people who take the trouble to put these archives on the internet.

[ 01-05-2007, 07:17 AM: Message edited by: Asquith ]

http://www.norfolkancestors.org/lsepics/manchester/txn/4.jpg

http://www.lselink.co.uk/images/lsepics/78.jpg

Two photos showing a pair of Ormerod shapers with a radial arm drill between them, for machining the feet of electric motors.

http://www.norfolkancestors.org/lsepics/manchester/txn/2.jpg

Churchill grinder, arranged like a horizontal borer. Note ‘War Finish’ stencilled on the machine.

http://www.lselink.co.uk/images/lsepics/5.jpg

SIP Jig borer

http://www.lselink.co.uk/images/lsepics/23.jpg

Wooden pattern

http://www.lselink.co.uk/images/lsepics/30.jpg

horiz borer

http://www.lselink.co.uk/images/lsepics/168.jpg

Special lathe

http://www.lselink.co.uk/images/lsepics/188.jpg

Dies

http://www.lselink.co.uk/images/lsepics/206.jpg

Asquith radial arm drill

http://www.lselink.co.uk/images/lsepics/212.jpg

Small grinder

http://www.lselink.co.uk/images/lsepics/219.jpg

Plano miller

http://www.lselink.co.uk/images/lsepics/226.jpg

Churchill cylindrical grinder

http://www.lselink.co.uk/images/lsepics/579.jpg

Grinder

http://www.lselink.co.uk/images/lsepics/232.jpg

http://www.lselink.co.uk/images/lsepics/261.jpg

Noble & Lund lathe

http://www.lselink.co.uk/images/lsepics/243.jpg

http://www.lselink.co.uk/images/lsepics/777.jpg

Craven VBM

http://www.lselink.co.uk/images/lsepics/427.jpg

Modeller

http://www.lselink.co.uk/images/lsepics/550.jpg

Sykes gear hobber

http://www.lselink.co.uk/images/lsepics/560.jpg

Webster & Bennett VBMs

http://www.lselink.co.uk/images/lsepics/581.jpg

Kendall & Gent miller

http://www.lselink.co.uk/images/lsepics/582.jpg

Parkson miller

http://www.lselink.co.uk/images/lsepics/583.jpg

http://www.lselink.co.uk/images/lsepics/584.jpg

Butler slotter

http://www.lselink.co.uk/images/lsepics/596.jpg

http://www.lselink.co.uk/images/lsepics/754.jpg

Butler planer

http://www.lselink.co.uk/images/lsepics/620.jpg

Craven planer

http://www.lselink.co.uk/images/lsepics/613.jpg

Long ago

http://www.lselink.co.uk/images/lsepics/636.jpg

Munition girls

http://www.lselink.co.uk/images/lsepics/789.jpg

Ship’s shaft(?) on Kearns horizontal borer. Jig fitted to coupling for boring bolt holes.

The photos above are from:-

http://www.norfolkancestors.org/lse/lsegallery.php

…and so far I’ve only scratched the surface!

Some more here, which I’ve only had a quick glance at ……

http://www.norfolkancestors.org/lse/laurenceintro.htm

An example…..

Small gear inspection

I’m very grateful to the people who take the trouble to put these archives on the internet.

[ 01-05-2007, 07:17 AM: Message edited by: Asquith ]