99Panhard

Stainless

- Joined

- Feb 22, 2006

- Location

- Smithfield, Rhode Island

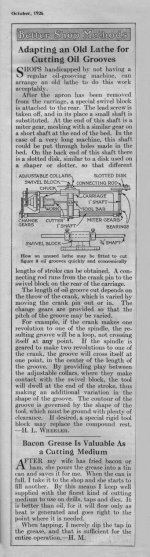

I'm thinking of making a machine to put grooves in bearings from this short piece in the October 1926 edition of Popular Science. It's within my capeabilities and it would be quite useful to me. But, I need something to make it out of. It can't be too large - a bench lathe of some sort would be perfect or a a small lathe like one of those "trade school" Reed & Prentice machines that someone has pilfered the legs from. I do not want to make it from an otherwise useful machine. I'm in Rhode Island so something in New England would be appropritae and, of couse, I don't want to pay much. That said, it's a chance to make someting that is otherwise scrap into something useful.

https://www.practicalmachinist.com/vb/images/attach/jpg.gif

https://www.practicalmachinist.com/vb/images/attach/jpg.gif