Nordberg survived into the nuclear era, and a few of their diesel engines were supplied as emergency/black start power to nuke powerplants. Nordberg began building diesel engines in the 'teens. I believe they used a Swedish design under license from a firm called "Carels". Marquette, MI, had a diesel power plant in their Board of Light & Power system. It had two 1920's Nordberg diesels, looking like open-frame marine steam engines. These were scrapped in the 1980's to make way for some gas turbine units. A buddy got me the nameplate off one of the engines, and the nickel-plated pressure gauges from the "blast air" compressor.

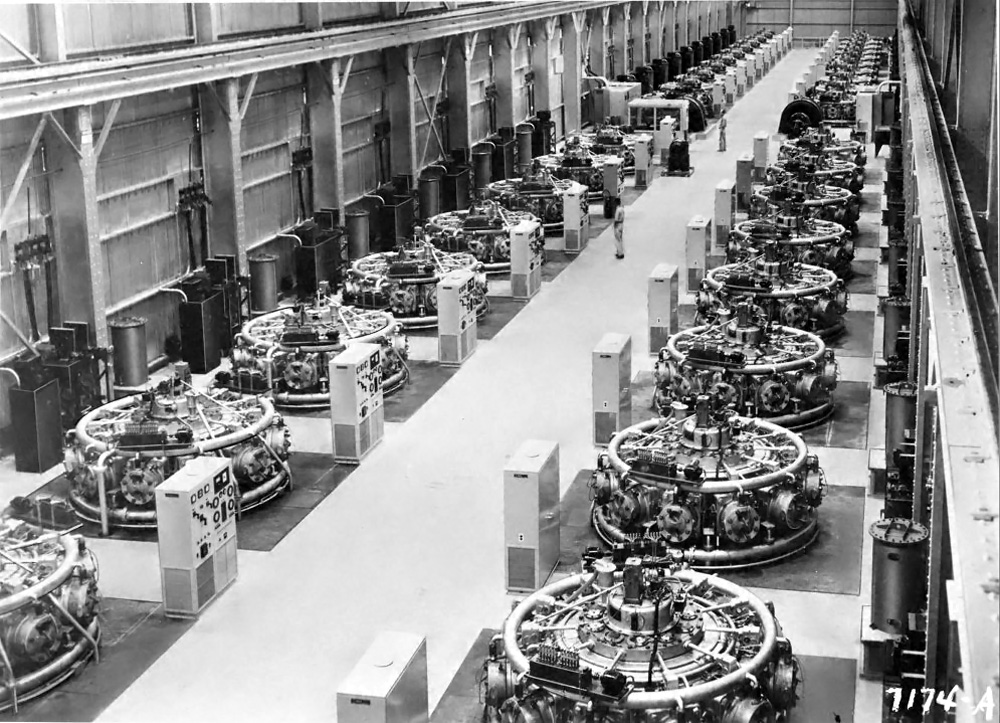

In that same plant there were some 1950's Nordbergs, which may still be there. Nordberg was quite a builder of diesel engines for powerplants and marine use. In Boston, MA, Nordberg furnished radial "dual fuel" engines (oil diesel and natural gas) to drive sewage lift pumps- replacing some radial Corliss steam engine drives. Other Nordberg radial diesel engines went into service driving generators in aluminum refining plants. Nordberg, in the 1960's was offering their diesels with what amounted to a variable valve timing system- known as their "Supair Thermal" engine control. This was used on stationary powerplant diesels and relied on a bunch of mechanical sensors and servomechanisms to accomplish the variable valve timing in response to load.

Bruno Nordberg was a prolific designer of engines, and while he did not live to see his firm get heavily into diesels, he left quite a legacy. Nordberg built what was one of the largest mine hoists in the world- the Quincy Mine Hoist. This is a four-cylinder Corliss driven hoist, preserved in situ at the old Quincy copper mine in the Upper Peninsula of Michigan. Nordberg did quite a bit of business in building mine hoists as well as Corliss engines.

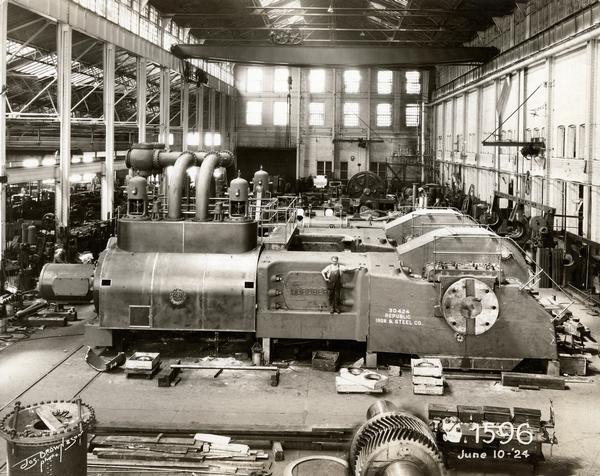

Nordberg built a variety of stationary steam engines, starting with Corliss engines. Later on, they built poppet valve engines with side-shaft drive for the valve gear. This looked like a Lenz design. Quite a few of the poppet valve stationary engines went into service in in-plant generating applications. A "pair" of Nordberg steam engines survive in service on the sternwheel steamboat "Natchez" running out of New Orleans. These engines (port and starboard) came off a US Army Engineer Corps dredge, I believe. They may have been the only engines Nordberg built for a sternwheel vessel. Nordberg stuck to stationary steam engine applications until WWII.

After WWII, Nordberg was experimenting (possibly with Doble, of the steam car fame) to develop a steam powered inner-city transit bus. One of the things they had was a separate auxiliary engine to run a generator, and that little engine was supposed to have been a nice piece of work in its own right. That project seems to have been erased from any books or records, just a few sentences about it.

I know Nordberg also built some smaller diesels for applications like running crushers or smaller sawmills, and after WWII, got into marine engines for pleasure boats. I imagine that when WWII ended, Nordberg suddenly had a lot of factory capacity and looked for something else to utilize it.

During WWII, Nordberg built Unaflow marine steam engines under license from Skinner for smaller aircraft carriers and other naval vessels. What Nordberg seemed to build the most of was rock crushers. These were all over the place, in quarry pit operations, cement mills, and anyplace a gyratory type of rock crusher could be used. Of all of Nordberg's products, I think the rock crushers were the only thing to survive, with the remnants of Nordberg going to form a company called "Rexnord".

I had always wondered what Nordberg's shops were like, and these photos answered some of my questions. Nordberg must have had square miles of shop space to build what they did. I do not know what killed Nordberg as a company. It seemed like the two giants in this sort of manufacturing were Allis-Chalmers and Nordberg, both in Milwaukee. Both are history as companies. Milwaukee, in its heydays, must have been quite a town. I was in Milwaukee to inspect a huge LeBlond lathe for sale off the floor of the old Louis-Allis motor plant in Cudahy. We bought that lathe, and at the time, the Louis-Allis plant was closed but intact- like the people would be able to come in and go right back to work. Across the street was the Filer and Stowell Company- still in business. They built quite a few very fine 4-valve non releasing steam engines, Corliss engines, sawmill machinery, and more. Also in Milwaukee was the Vilter company- builders of Corliss engines to drive their Ammonia refrigeration pumps, a big name in the brewing industry. Kearny & Trecker was in Milwaukee, and I am sure there were other machine tool builders. Most people thing of Milwaukee in terms of either the home of Harley Davidson, or for breweries. Most of the old-line breweries in Milwaukee have closed, and H-D has shifted most of its manufacturing to other locations, maintaining a headquarters and engineering center in Milwaukee. P & H was known the world over, and they are now part of some bigger conglomerate. Whether they are still in Milwaukee is something I do not know. It's hard to imagine the effect that the closure of firms like Nordberg and A-C must have had on Milwaukee. I am sure there must be at least a score of big shops that pulled out of Milwaukee aside from these two. Now, it's a matter of looking at photos to see what was there. Aside from seeing a few Nordberg diesels, and having a nameplate and gauges from them on the wall, I can't help but wonder what the plant was like when I glance at the nameplate and gauges. Thanks for posting the photos.

Maybe someday I'm going to get me 1 of those lathes. Not sure what I'd do with it

Maybe someday I'm going to get me 1 of those lathes. Not sure what I'd do with it ,... but it'd sure look impressive sitting in my shop. Well,... part way in my shop & part way sticking out the hole in the wall.

,... but it'd sure look impressive sitting in my shop. Well,... part way in my shop & part way sticking out the hole in the wall.