Honor and Pleasure

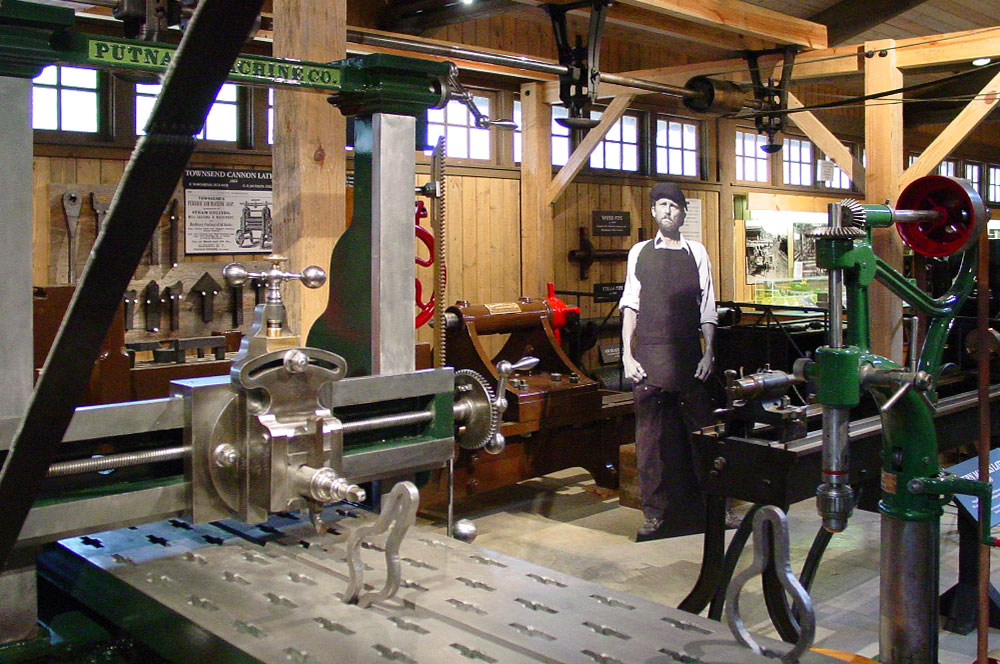

I'm planning to make a trip to Walter's Saturday exercising visitation rights to "our" P&W shaper. Besides he really has the shop cleaned up. In my opinion, it always looks great, much cleaner and better organized than my shop.

Walter is an outstanding person. Contributes greatly to preservation of old iron. Besides his shop, as he mentioned, a planer at Tannahill, in McCulla, AL.

And not just machine tools. He has restored many a steam engine, repairing and correcting weak designs in process. The Corliss steam engine at Soule' in Meridian, MS, which he cares for and exhibits during the November show.

Our meeting was due to the first showing of my FLASH exhibit, in 2011. He missed that tractor & engine show, only one he has missed at that venue. Some of his colleagues, informed him of the machines in my exhibit. It took him 2 weeks to locate me, and after a phone call, arrived in just over an hour for a visit and viewing of my exhibit.

My exhibit is a missed "link" in many peoples understanding of machine tool development.

He is knowledgeable, and shares this knowledge of old printing presses. Turned on TV to catch noon news in Huntsville, AL, and they were interviewing an author about a new book on printing. The author credited Walter, with information Walter had shared.

Walter served as a firefighter, which drives the firefighting items seen in his shop. He has restored some fire trucks also.

You should see his board drawn prints, he exhibits on wall of shop. Truly art to real machinist.

It has been an honor and pleasure to meet him and share our common interest in old iron.

Walter hangs out here and will likely read this unsolicited post. Monetary compensation may be accepted, especially large bills, however not over $100!!!

Ray