rivett608

Diamond

- Joined

- Oct 25, 2002

- Location

- Kansas City, Mo.

Here is the tall case clock from that miniature house built in the 1950's, the house was mentioned in this thread. The clock case was made by Frank L. Matter and the Jager-LeCoultre movement supplied

http://www.practicalmachinist.com/vb/showthread.php/need-help-tracking-down-192275.html

This clock is only 1 5/8" tall as can be seen next to a #11 x-acto knife blade....

Here it is in the room in the little house for which it was made.... this photo was taken in 1958 or 59.....

Now this guy needs some work.... it is missing some molding and the finials... and the clock does not run...... so I get to take it apart!!!!!

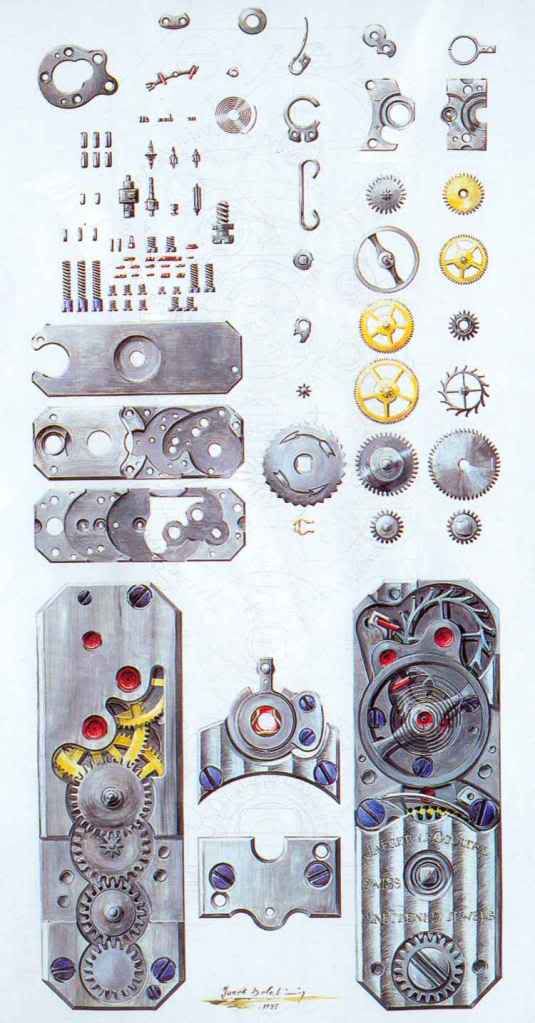

The amazing thing about this is the clock keeps time with a mechanical movement that just happens to be the smallest type in the world!!!!!! It was designed in 1929 and they are still being made after 80 years......... read all about them..... they are amazing!

http://www.luxist.com/2009/08/11/jaeger-lecoultre-calibre-101-smallest-mechanical-watch-movement/

http://www.gregoryswatches.com/watches/lecoultre_cal101.html

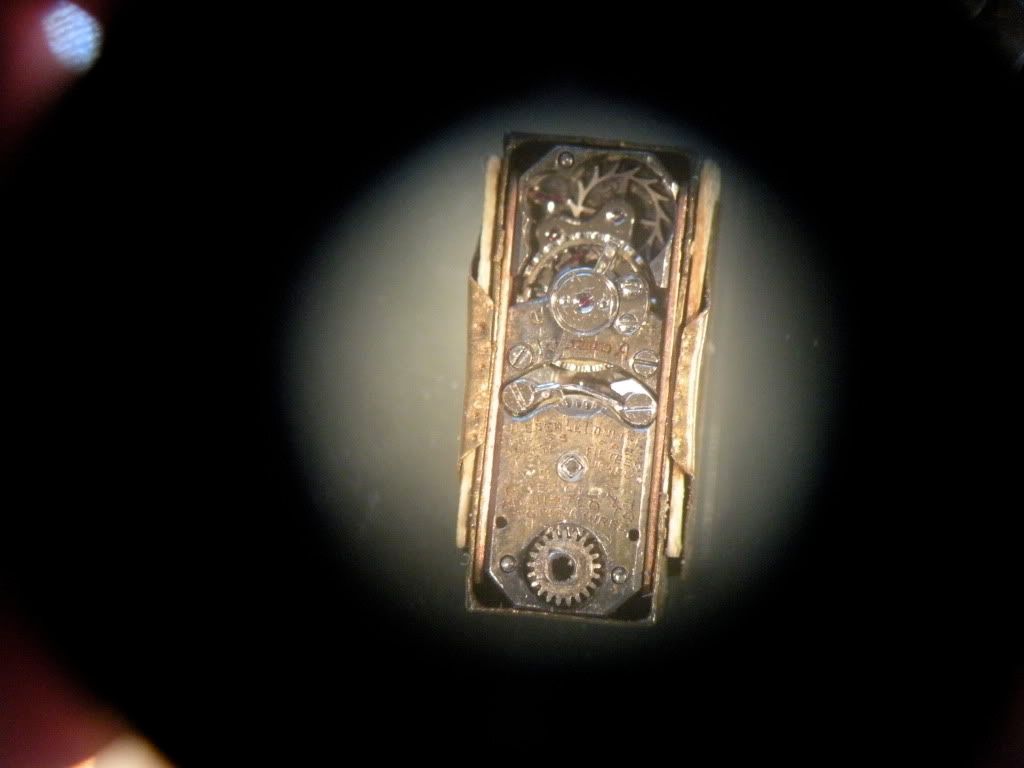

and here it is under the microscope.....

Now one of the reasons it did not work is someone lost the Winding Crown Screw p/n# 5912....... believe it or not of the one part listed on Borel's material site this was the part the computer showed they had.... but of course the drawer was empty when I ordered it!!!! So I need a screw....... this screw is a 0.8 mm LEFT hand thread about 2 mm long..... and that is a die I do not have...... anyone have one? Larry?

On a side note I was at a friends yesterday (I am back east for the holiday) and we looked through his collection of dozens of watchmakers screw plates..... most marked "B" or "L"...... I always thought the "L" was left hand..... it was not.... so what does "B" & "L" on screw plates mean?.....

By the way someone later had tried to epoxy a right hand screw into the hole.... that was a mess to clean up....... the movement now runs but on of the hands is dragging a little..... and I just have to come up the right screw...... and the molding and finials are also fixed........ the wood of the case is Bulletwood or Beefwood or Bloodwood..... very hard, interesting grain but also very brittle.... not the easiest stuff to work in.....

Enjoy!

http://www.practicalmachinist.com/vb/showthread.php/need-help-tracking-down-192275.html

This clock is only 1 5/8" tall as can be seen next to a #11 x-acto knife blade....

Here it is in the room in the little house for which it was made.... this photo was taken in 1958 or 59.....

Now this guy needs some work.... it is missing some molding and the finials... and the clock does not run...... so I get to take it apart!!!!!

The amazing thing about this is the clock keeps time with a mechanical movement that just happens to be the smallest type in the world!!!!!! It was designed in 1929 and they are still being made after 80 years......... read all about them..... they are amazing!

http://www.luxist.com/2009/08/11/jaeger-lecoultre-calibre-101-smallest-mechanical-watch-movement/

http://www.gregoryswatches.com/watches/lecoultre_cal101.html

and here it is under the microscope.....

Now one of the reasons it did not work is someone lost the Winding Crown Screw p/n# 5912....... believe it or not of the one part listed on Borel's material site this was the part the computer showed they had.... but of course the drawer was empty when I ordered it!!!! So I need a screw....... this screw is a 0.8 mm LEFT hand thread about 2 mm long..... and that is a die I do not have...... anyone have one? Larry?

On a side note I was at a friends yesterday (I am back east for the holiday) and we looked through his collection of dozens of watchmakers screw plates..... most marked "B" or "L"...... I always thought the "L" was left hand..... it was not.... so what does "B" & "L" on screw plates mean?.....

By the way someone later had tried to epoxy a right hand screw into the hole.... that was a mess to clean up....... the movement now runs but on of the hands is dragging a little..... and I just have to come up the right screw...... and the molding and finials are also fixed........ the wood of the case is Bulletwood or Beefwood or Bloodwood..... very hard, interesting grain but also very brittle.... not the easiest stuff to work in.....

Enjoy!