rivett608

Diamond

- Joined

- Oct 25, 2002

- Location

- Kansas City, Mo.

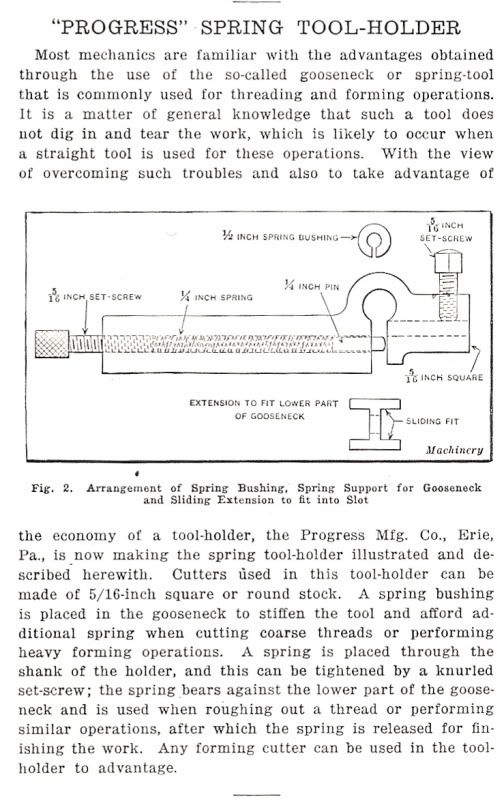

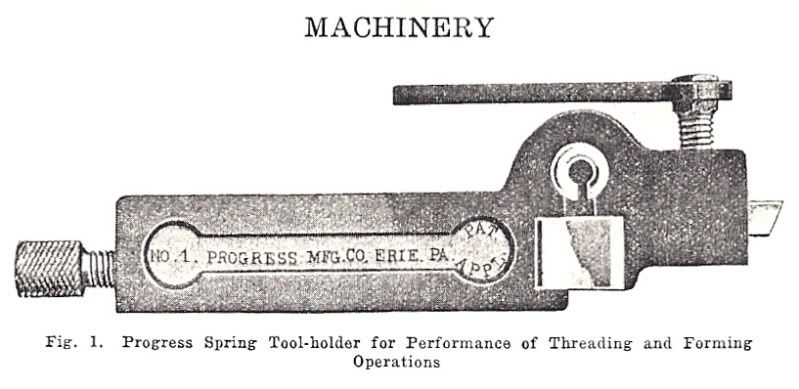

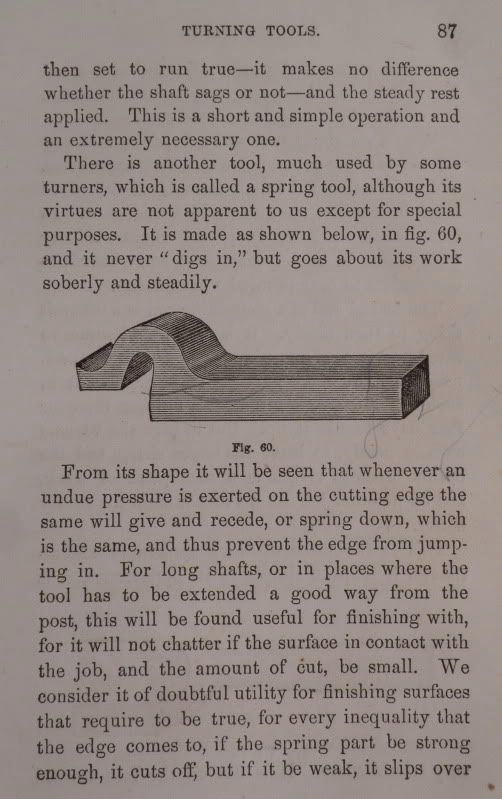

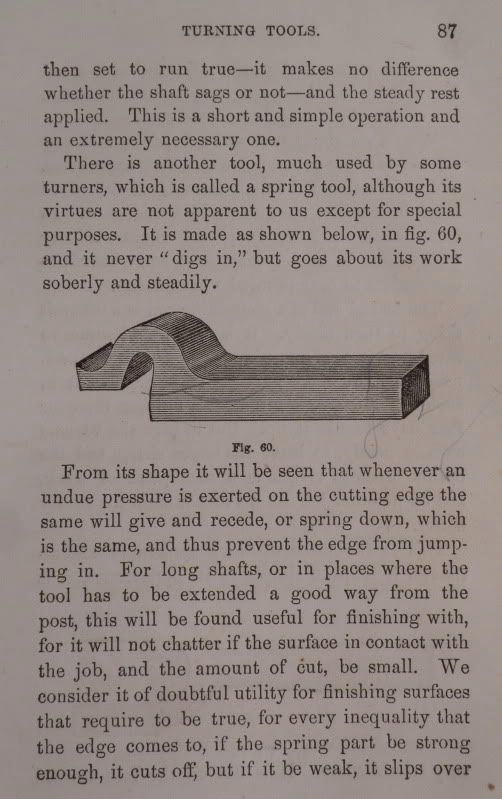

Seeing SB34's nice find I kept thinking I had seen this in a early book........ so I looked for it and found shortly.... This is from "The Modern Practice of American Machinists and Engineers" by Egbert P. Watson, 1867

On the next page it mentions you can put a small wedge in it making it a solid tool....

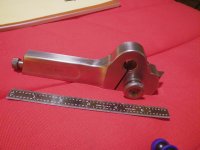

And here is a cute little one I found ages ago.... it has a 5/16" x 7/16" shank...... the part I like is the little wrench that stores in the back..... also notice on the bottom it has a feature of a dovetailed slide to let it spring but not move side to side. Another thing is I wonder if the inner spring is removable to give it both a soft and stiff setting????? With the grinding marks I would guess it to be early 20th century.

On the next page it mentions you can put a small wedge in it making it a solid tool....

And here is a cute little one I found ages ago.... it has a 5/16" x 7/16" shank...... the part I like is the little wrench that stores in the back..... also notice on the bottom it has a feature of a dovetailed slide to let it spring but not move side to side. Another thing is I wonder if the inner spring is removable to give it both a soft and stiff setting????? With the grinding marks I would guess it to be early 20th century.