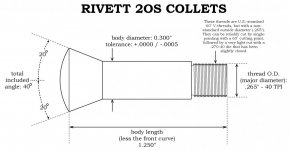

The collets are Rivett number 1R, which were made for the model 1R watchmaker lathe.

This lathe was introduced after WWII to fill the needs of the GI's taking watch repair classes. Rivett, like Hardinge, saw demand for their toolroom lathes drop sharply after the war. The 1R was an attempt to keep the factory in business until orders for the big stuff recovered. They were designing the big expensive 1020, which was introduced in 1953. The 1R was an all new design in the Art Deco style, unlike any other watch lathe before or since. I have two and will take some pictures later. A unique feature at the time was a sealed ball bearing spindle with the drive pulley cantilever mounted on the left end.

Rivett started out in the late 1800's making watchmaker lathes in Boston. They were in competition with American Watch Tool in Waltham, the originator of the popular Webster Whitcomb lathe design. Rivett lathes were more expensive, so they did not sell as well. The AWT watch lathe line was later bought out by F.W. Derbyshire, still in business in the Boston area. I heard that Derbyshire eventually bought out the remains of the Rivett watch lathe business. Wade bought out the AWT large machine line and is also still in business in the Boston area.

The old Rivett watch lathes used collets that did not fit any other make of lathe. The Webster Whitcomb collet design were eventually used by almost every watch lathe maker in the world. Derbyshire still owns the name Webster Whitcomb, but Levin in Los Angeles called their collets of that type "WW" and the name caught on.

So, in the late 1940's, almost every watchmaker was using WW collets. Rivett had no reason to try to revive their obsolete collet design, which they had not made for decades. Instead, they wisely decided to make their new 1R lathe use WW collets. Perhaps as a marketing trick, they made their own WW collets and marked them "1R."

The 1R lathe did not become popular. It must have been priced higher than the Marshall Peerless lathe, which is the most commonly found lathe of that period. UK Tony's lathe site says five or six hundred 1R's were made. My 1R's are serial number 89 and 451.