M.B. Naegle

Diamond

- Joined

- Feb 7, 2011

- Location

- Conroe, TX USA

So I'm no longer a proud Logan lathe owner. I sold my model 200 a couple years ago, and my 820 went away on Monday (I kept my T-shirt though!). I'm still set with small tool-room lathes so other than the regret of letting go of old iron, I can still turn parts. Letting go of the 820 made some room, which my wife loved, but I got the eye-roll this morning when she saw what I drug into the garage last night.

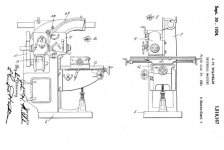

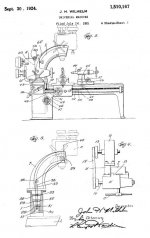

I struck a deal with a gentleman south of Houston for an Ames Triplex. It's fairly complete minus a few small pieces. Biggest issue at the moment is that the spindle was partially disassembled by a prior owner. Not sure what the issue was, so I'm doing visual inspection, cleaning out the gear-box, and putting it back together to start with. I don't have time to do a full rebuild right now, so I'm going to focus of getting it running and learning all I can about it.

There's a good write-up on Lathes.uk Ames Triplex Multi-function machine and a couple other threads on here giving some spindle info and pictures of other machines, but not a lot else, so I'll share what I learn as it comes.

Mill-Lathes get a bad wrap in general as they're a "jack-of-all, master-of-none" machine, but some initial impressions of this machine now that I have my hands on one is that for its limited size range, it looks fairly ridged and well built. Regardless of how it was marketed, I get the impression that it won't completely replace a mill and lathe, but the size and adaptability of it make it a great 2nd-op machine.

There's no power feeds or screw-cutting capability, but the spindle has 3 geared speeds and a 2 step belt drive (6 speed head). It has a small but present through-bore that's in the range of a 9" tool room lathe, and accepts tooling in the size/power range of an M-head Bridgeport mill. The ways are built similar in size to a 10" South Bend.

It looks like you can quickly set it up, but to what accuracy I want to learn. Once it's running, I want to see how well everything holds tram and how repeatable it is. So, pictures to come...

I struck a deal with a gentleman south of Houston for an Ames Triplex. It's fairly complete minus a few small pieces. Biggest issue at the moment is that the spindle was partially disassembled by a prior owner. Not sure what the issue was, so I'm doing visual inspection, cleaning out the gear-box, and putting it back together to start with. I don't have time to do a full rebuild right now, so I'm going to focus of getting it running and learning all I can about it.

There's a good write-up on Lathes.uk Ames Triplex Multi-function machine and a couple other threads on here giving some spindle info and pictures of other machines, but not a lot else, so I'll share what I learn as it comes.

Mill-Lathes get a bad wrap in general as they're a "jack-of-all, master-of-none" machine, but some initial impressions of this machine now that I have my hands on one is that for its limited size range, it looks fairly ridged and well built. Regardless of how it was marketed, I get the impression that it won't completely replace a mill and lathe, but the size and adaptability of it make it a great 2nd-op machine.

There's no power feeds or screw-cutting capability, but the spindle has 3 geared speeds and a 2 step belt drive (6 speed head). It has a small but present through-bore that's in the range of a 9" tool room lathe, and accepts tooling in the size/power range of an M-head Bridgeport mill. The ways are built similar in size to a 10" South Bend.

It looks like you can quickly set it up, but to what accuracy I want to learn. Once it's running, I want to see how well everything holds tram and how repeatable it is. So, pictures to come...

).

).

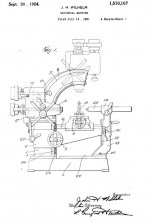

. The original owner is looking for it, but I may need to make one. I'll need to figure the dovetail angle, arc radius, and hole positions, but I'll have to make it in one of our CNC mills as I don't have any way to manually generate an arc that big (at least not practically), so I'll model it in CAD and let the machine do the work.... unless we find the old one! That's my hope.

. The original owner is looking for it, but I may need to make one. I'll need to figure the dovetail angle, arc radius, and hole positions, but I'll have to make it in one of our CNC mills as I don't have any way to manually generate an arc that big (at least not practically), so I'll model it in CAD and let the machine do the work.... unless we find the old one! That's my hope.

. So if anyone ever needs to replace it: 7" radius and a 60 degree angle is what you're after. Now I just need to finish the mounting hole and alignment pins.

. So if anyone ever needs to replace it: 7" radius and a 60 degree angle is what you're after. Now I just need to finish the mounting hole and alignment pins.