Terry Harper

Cast Iron

- Joined

- Sep 3, 2009

- Location

- Maine USA

Its always good when you can involve youth in a project. For quite awhile we have wanted a set of sleds to go along with our 19 ton steam Lombard Log Hauler at the Maine Forest & Logging Museum.

Mind you, back in the day, horse drawn "two sled" rigs were the common method of moving heavy loads of logs from the cuttings to the landings up here in the northeast during the winter months.

When Lombard developed his log hauler in 1900 he quickly realized that the relatively light sleds then in use where not suitable for the heavy work a steam Lombard could perform so he developed and patented his own design and for decades offered "kits" of sled irons to woods operators.

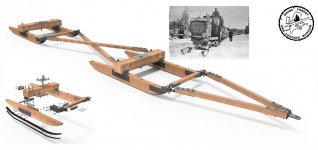

Note in the drawing below the crossed reach poles. These allowed a long train of sleds to be fully articulated yet allowed each sled to "steer" the sleds following along in the same track. Since the runners had a tendency to freeze in they usually tried to start the load at a slight angle to break them free. Also, and I hadn't thought about this before until I studied the drawings, the pins for the draw bar and reach poles ran in slotted holes. This allowed slack to be taken so the load could be started gradually rather than all at once.

For peak efficiency each Lombard required three sets of sleds - one set being loaded, another set being unloaded and a third set moving over the road. How many sleds per train (typically 8-10) depended upon the hauling conditions. Lombard offered smaller, lighter sleds for gas Lombard log haulers.

One operation had 944 sleds - or enough to make 472 complete "two-sled" rigs. Each sled costing $192.70 All these sleds were to support a fleet of 15 gasoline powered Lombards.

Back a number of years ago the Breton's donated a set of Lombard sled irons. They sat pretty much forgotten until we "found" them again this spring. Last week the iron was loaded into a van along with a pile of heavy oak timber (cut by the museum's "Tuesday Crew") for the 3 hour drive north to the Presque Isle Regional Career & Technical Center.

Over the next few months our students in the Building Trades and Farm Mechanic's programs will work to disassemble and clean-up the jumble of iron and remove dozen's of long seized bolts and nuts. Then start rebuilding the whole thing into a complete sled assembly.

Our students love what we call "Live work projects" These are projects that allow our High School age students to learn skills by working on real projects and interface with industry and the community. Usually the client will provide materials or make a donation to cover the costs.

All good fun!

Best regards

Terry

Mind you, back in the day, horse drawn "two sled" rigs were the common method of moving heavy loads of logs from the cuttings to the landings up here in the northeast during the winter months.

When Lombard developed his log hauler in 1900 he quickly realized that the relatively light sleds then in use where not suitable for the heavy work a steam Lombard could perform so he developed and patented his own design and for decades offered "kits" of sled irons to woods operators.

Note in the drawing below the crossed reach poles. These allowed a long train of sleds to be fully articulated yet allowed each sled to "steer" the sleds following along in the same track. Since the runners had a tendency to freeze in they usually tried to start the load at a slight angle to break them free. Also, and I hadn't thought about this before until I studied the drawings, the pins for the draw bar and reach poles ran in slotted holes. This allowed slack to be taken so the load could be started gradually rather than all at once.

For peak efficiency each Lombard required three sets of sleds - one set being loaded, another set being unloaded and a third set moving over the road. How many sleds per train (typically 8-10) depended upon the hauling conditions. Lombard offered smaller, lighter sleds for gas Lombard log haulers.

One operation had 944 sleds - or enough to make 472 complete "two-sled" rigs. Each sled costing $192.70 All these sleds were to support a fleet of 15 gasoline powered Lombards.

Back a number of years ago the Breton's donated a set of Lombard sled irons. They sat pretty much forgotten until we "found" them again this spring. Last week the iron was loaded into a van along with a pile of heavy oak timber (cut by the museum's "Tuesday Crew") for the 3 hour drive north to the Presque Isle Regional Career & Technical Center.

Over the next few months our students in the Building Trades and Farm Mechanic's programs will work to disassemble and clean-up the jumble of iron and remove dozen's of long seized bolts and nuts. Then start rebuilding the whole thing into a complete sled assembly.

Our students love what we call "Live work projects" These are projects that allow our High School age students to learn skills by working on real projects and interface with industry and the community. Usually the client will provide materials or make a donation to cover the costs.

All good fun!

Best regards

Terry