Wow, This has generated a lot of interest. I think I'll peruse the antique section more often.. I bought this beautiful old machine because I fell in love with it as soon as I saw it.

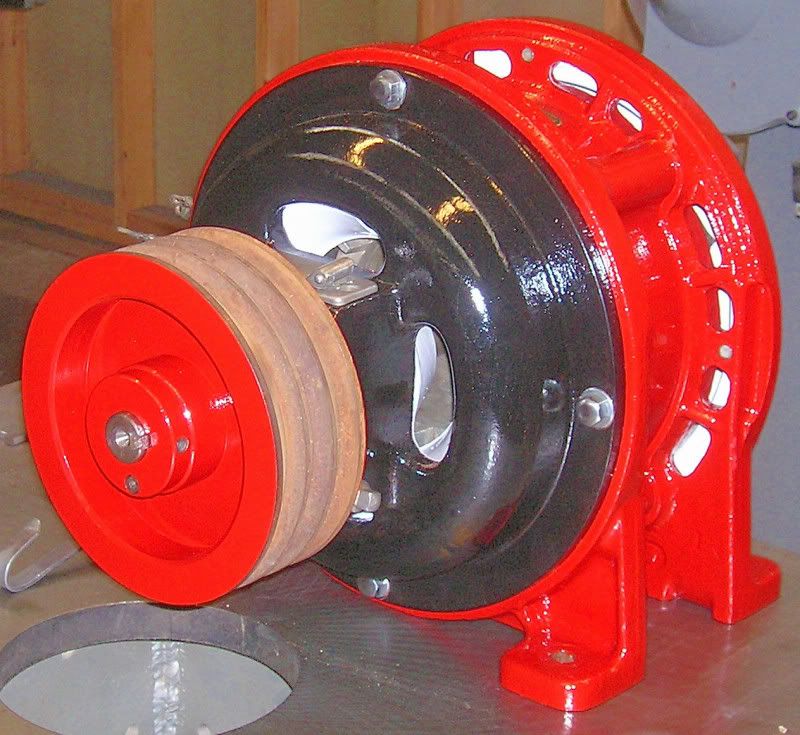

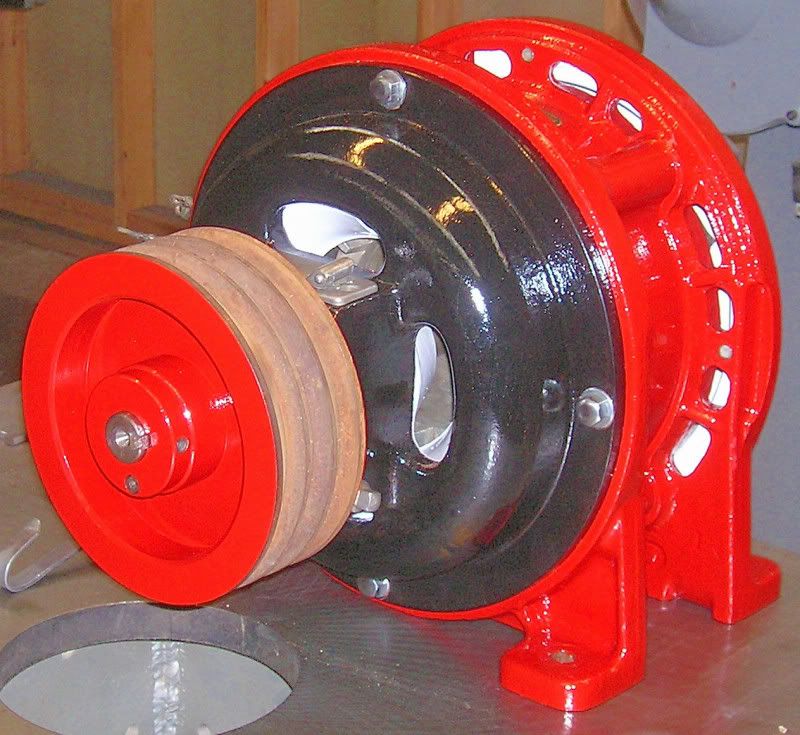

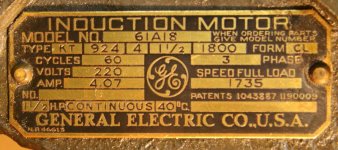

Bruce, (and others), here is a few more photos of my motor. After closer examination and your question about mounting, I must say I am not absolutely sure this is the original motor. But, I think it most likely is. Notice the oil reservoir cover in the front view. It is obvious this is not original, but a well made home (or shop) version, a flat cover. Also this B&S had a modern steel plate with drilled and tapped holes installed that the motor was mounted to. The original machine casting has three holes for motor mounting and I can not envision how the original motor was mounted using these holes. One possibility is that the leather belts were replaced with a modern composite flat belt and the plate may have been needed to adjust the short belt tension, that runs the table drive. The motor is adjusted left to right for tensioning the table drive belt. The long belt, which runs the spindle, has a weighed tension adjusting/compensating arm that allows the belt to maintain tension while the spindle head moves up and down. Since this motor mounting plate is 1/2 inch thick, making the motor higher, I assume the oil cover was too tall to clear the top of the hole in the casting, because the shaft and part of the bearing (bell) housing that sticks out through this hole. Note the shaft (3.000") is almost too short and does not extend to the edge of the pulley. You can see this in the rear view if the B&S photo.

So if anyone has an extra oil cover and wants to part with it, please let me know. I think I can make an adjustment in the thickness of this plate to get more clearance.

Referencing this chart at:

http://www.joliet-equipment.com/sales/motorframechart.php

There is no NEMA frame type because the motor is pre-NEMA code. But, using the code dimensions from the above link the measurments are:

D=5.4375" (5-7/16)

E=9.000"

F=5.125"

U=1.000" (shaft Diameter)

V=3.000" (Shaft length)

The max end bell diameter (minus mounting flange) is 8-11/16th "

Max Diameter of frame is 10=15/16ths"

Frame (between end bell flanges) is 5"

Joe