CWC(4)

Cast Iron

- Joined

- Jan 2, 2017

- Location

- North Central MA

I could a little help with this old lathe a friend gave me a couple of years ago.

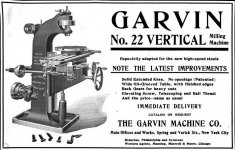

The tag on the front of the machine (pictured)shows "the Garvin Machine Co., Machinery and Tools, New York". This tag is not attached as they typically were with pins or drive screws in the four corners rather than the way that's shown, which makes me wonder if this is a Garvin or is that just the company that sold/serviced them.

It looks 1900-ish to me and any info about the actual age or manufacture, is appreciated.

Lathe has a 5'bed and a 12" swing (slightly under, @ about 11 3/4").

Ultimately, I would like to find a tail stock for it but I know that's probably a long shot. I'm hoping to put it into light use and preserve it because of the historic shop that it came out of when it closed around 1970. My friend salvaged it at that time and has had it ever since. If he hadn't saved it, it would have been left behind and more than likely sold for scrap.

Thanks in advance for any help.

CWC(4)

The tag on the front of the machine (pictured)shows "the Garvin Machine Co., Machinery and Tools, New York". This tag is not attached as they typically were with pins or drive screws in the four corners rather than the way that's shown, which makes me wonder if this is a Garvin or is that just the company that sold/serviced them.

It looks 1900-ish to me and any info about the actual age or manufacture, is appreciated.

Lathe has a 5'bed and a 12" swing (slightly under, @ about 11 3/4").

Ultimately, I would like to find a tail stock for it but I know that's probably a long shot. I'm hoping to put it into light use and preserve it because of the historic shop that it came out of when it closed around 1970. My friend salvaged it at that time and has had it ever since. If he hadn't saved it, it would have been left behind and more than likely sold for scrap.

Thanks in advance for any help.

CWC(4)