JHOLLAND1

Titanium

- Joined

- Oct 8, 2005

- Location

- western washington state

22 years ago I purchased 1950's J+L turret lathe from Dept of Defense

the saddle/carriage had been removed and cnc slant bed retrofit placed

4.5 inch spindle thru hole

included was hydraulic bar feed with passive-slave chuck which

mounted into headstock bracket with 3 in bar stock

for past 22 years machine has occupied shed--never used

and the slave chuck oxidizing in underbrush

but now lathe is needed to machine 4 inch driveshaft for fire truck conversion

so I am in process of slave chuck teardown

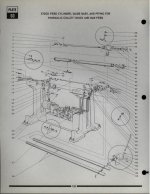

pics illustrate 7 inch j-l turret machine which is otherwise identical to the

4-1/2 inch machine I reference

the saddle/carriage had been removed and cnc slant bed retrofit placed

4.5 inch spindle thru hole

included was hydraulic bar feed with passive-slave chuck which

mounted into headstock bracket with 3 in bar stock

for past 22 years machine has occupied shed--never used

and the slave chuck oxidizing in underbrush

but now lathe is needed to machine 4 inch driveshaft for fire truck conversion

so I am in process of slave chuck teardown

pics illustrate 7 inch j-l turret machine which is otherwise identical to the

4-1/2 inch machine I reference