Good morning,

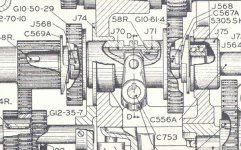

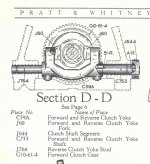

Yesterday I was turning down a gear blank and the lead screw stopped turning. It has been making a banging noise when I engage the feed lever for a little while now and I thought the tooth was worn. Now the toothed clutch won't engage in either direction. The feed lever still moves but the lead screw isn't turning.

What happened? I can only imagine a gear broke, but it was running and the lead screw was turning when I was cutting the blank and when I went to take the next cut it had stopped. I didn't hear any unusual sound during that time, either.

Also, what is the disassembly procedure to get to that area of the headstock? Everything looks like it has to come off before something else.

I'm a one-lathe shop and I'm stopped now. I'm on bended knee here. Thank you very much for any help you can provide.

Yesterday I was turning down a gear blank and the lead screw stopped turning. It has been making a banging noise when I engage the feed lever for a little while now and I thought the tooth was worn. Now the toothed clutch won't engage in either direction. The feed lever still moves but the lead screw isn't turning.

What happened? I can only imagine a gear broke, but it was running and the lead screw was turning when I was cutting the blank and when I went to take the next cut it had stopped. I didn't hear any unusual sound during that time, either.

Also, what is the disassembly procedure to get to that area of the headstock? Everything looks like it has to come off before something else.

I'm a one-lathe shop and I'm stopped now. I'm on bended knee here. Thank you very much for any help you can provide.