How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

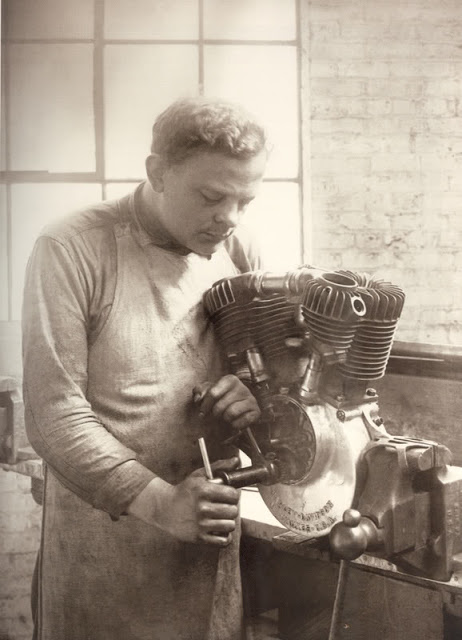

...Photo...Harley Davidson Engine Assembly...

- Thread starter lathefan

- Start date

- Replies 39

- Views 5,217

Greg Menke

Diamond

- Joined

- Feb 22, 2004

- Location

- Baltimore, MD, USA

This must be a stage in the line before they bolt on the chrome skulls?

Larry Dickman

Titanium

- Joined

- Jan 30, 2014

- Location

- Temecula, Ca

I visited the HD engine plant back in '92. Fortunately everything was in color then.

Servicar rider

Cast Iron

- Joined

- Sep 6, 2008

- Location

- Coggon Iowa usa

JD model engine last made in 1929!

Joe Michaels

Diamond

- Joined

- Apr 3, 2004

- Location

- Shandaken, NY, USA

Servicar Rider:

Thanks for validating my "educated guess" that this was a JD series engine. The JD series was an "F" head engine. I saw a 1928 JD model being ridden at a motorcycle event years ago. I remember seeing the rocker arms working, out in the open. Cool to look at, but, if I remember correctly, the rocker arms had to be oiled manually. Those open rocker arms probably left a mess of oil on the rider's thighs, aside from collecting a mess of grunge when road dust mixed with the oil on the open rocker arms. Back 'in the day' when the JD was in production, roads outside of cities were mainly dirt or "improved" with gravel. Road dust was a fact of life.

It took a different breed of rider to own and ride motorcycles back in those days, and any rider had to be a pretty fair mechanic. Rigid rear frames (aka "hard tails") on the motorcycles and spring suspension on the rider's saddle were what was standard. Combined with roads that were bad more often than not, both the motorcycle and the rider took a pounding. The owner's manual for the JD motorcycles must have had a lot more information about mechanical maintenance than the modern H-D manual contain. And, those motorcycles probably came with a place to store a tool-kit, unlike several generations of the newer H-D's.

An interesting process was the building of the motorcycle frames back in that era. Frames were made by bending steel tubing and fitting it into forgings or malleable iron castings for the steering neck and other major connections on the frame. Joining was done by bronze brazing. On the heavier joints, such as the steering neck, heating of the assembled portion of the frame with the heavy steering neck was done using a charcoal fired forge hearth. The tubing and sockets in the steering neck were fluxed beforehand. The frame was clamped in an assembly fixture or jig to hold everything in position, and the section of the frame with the steering neck went into the charcoal fire. When it was hot enough, bronze brazing rod was applied to the joints and some localized heating with an oxyacetylene torch was done. The brazing alloy used "wicked" into the joints and made small and very neat fillets. I remember seeing an old photo of the forge brazing of H-D frames, and always thought it took a good deal of skill to perform that kind of brazing.

The JD model was built at a time when the "founding fathers" of The Motor Company (as Harley Davidson used to be known amongst riders) were alive, well, and involved in the design and production of the JD series of engines and motorcycles. It was a time when Milwaukee, Wisconsin was alive with industry of all types, and firms such as Allis-Chalmers, Nordberg, Filer & Stowell, P & H, Kearney & Trecker, Vilter, and many more were producing heavy industrial machinery of all sorts ranging from milling machines to turbines and large steam and diesel engines. Ole Evinrude was alive and well, and had helped the "boys" (the young Harley and the Davidsons) to perfect a working carburetor for their first motorcycle engines. The JD was built in 1928-29, so Prohibition was likely in force and the brewing industry in Milwaukee was probably producing "near beer" and "pharmaceutical alcohol" if they were working at all. Despite prohibition, Milwaukee at the time the JD motorcycles were built, was probably a very thriving city with all sorts of industries and "spin-offs" such as smaller tool-&-die shops and supply firms all going full bore. A different era, for sure.

Thanks for validating my "educated guess" that this was a JD series engine. The JD series was an "F" head engine. I saw a 1928 JD model being ridden at a motorcycle event years ago. I remember seeing the rocker arms working, out in the open. Cool to look at, but, if I remember correctly, the rocker arms had to be oiled manually. Those open rocker arms probably left a mess of oil on the rider's thighs, aside from collecting a mess of grunge when road dust mixed with the oil on the open rocker arms. Back 'in the day' when the JD was in production, roads outside of cities were mainly dirt or "improved" with gravel. Road dust was a fact of life.

It took a different breed of rider to own and ride motorcycles back in those days, and any rider had to be a pretty fair mechanic. Rigid rear frames (aka "hard tails") on the motorcycles and spring suspension on the rider's saddle were what was standard. Combined with roads that were bad more often than not, both the motorcycle and the rider took a pounding. The owner's manual for the JD motorcycles must have had a lot more information about mechanical maintenance than the modern H-D manual contain. And, those motorcycles probably came with a place to store a tool-kit, unlike several generations of the newer H-D's.

An interesting process was the building of the motorcycle frames back in that era. Frames were made by bending steel tubing and fitting it into forgings or malleable iron castings for the steering neck and other major connections on the frame. Joining was done by bronze brazing. On the heavier joints, such as the steering neck, heating of the assembled portion of the frame with the heavy steering neck was done using a charcoal fired forge hearth. The tubing and sockets in the steering neck were fluxed beforehand. The frame was clamped in an assembly fixture or jig to hold everything in position, and the section of the frame with the steering neck went into the charcoal fire. When it was hot enough, bronze brazing rod was applied to the joints and some localized heating with an oxyacetylene torch was done. The brazing alloy used "wicked" into the joints and made small and very neat fillets. I remember seeing an old photo of the forge brazing of H-D frames, and always thought it took a good deal of skill to perform that kind of brazing.

The JD model was built at a time when the "founding fathers" of The Motor Company (as Harley Davidson used to be known amongst riders) were alive, well, and involved in the design and production of the JD series of engines and motorcycles. It was a time when Milwaukee, Wisconsin was alive with industry of all types, and firms such as Allis-Chalmers, Nordberg, Filer & Stowell, P & H, Kearney & Trecker, Vilter, and many more were producing heavy industrial machinery of all sorts ranging from milling machines to turbines and large steam and diesel engines. Ole Evinrude was alive and well, and had helped the "boys" (the young Harley and the Davidsons) to perfect a working carburetor for their first motorcycle engines. The JD was built in 1928-29, so Prohibition was likely in force and the brewing industry in Milwaukee was probably producing "near beer" and "pharmaceutical alcohol" if they were working at all. Despite prohibition, Milwaukee at the time the JD motorcycles were built, was probably a very thriving city with all sorts of industries and "spin-offs" such as smaller tool-&-die shops and supply firms all going full bore. A different era, for sure.

john.k

Diamond

- Joined

- Dec 21, 2012

- Location

- Brisbane Qld Australia

The motor in the picture is a 74 (1200cc) ,identified by the seven fins on the exhaust port ...the 61 (1000cc) has five....I have a FD 1928,a 74 ci with magneto ignition ....A 100 mph motor bike with near zero brakes ..a single external band on the back wheel ,with a separate internal band in the same drum to be use as a sidecar parking brake (pedal has a ratchet lock)....Lots of owners install the WW2 WLA front wheel brake ,so the brakes are just dangerous ,not suicidal.

johnoder

Diamond

- Joined

- Jul 16, 2004

- Location

- Houston, TX USA

JD model engine last made in 1929!

Had one - what a disaster. It would either crap out because of the disintegrating cork float - or the amazingly wimpy cam gears lost another tooth or so.

5 bucks from the neighbor when I was 15. Got to learn how to relace a wheel - in order to get rid of the 21" clincher that was on the back.

Greg Menke

Diamond

- Joined

- Feb 22, 2004

- Location

- Baltimore, MD, USA

IIRC somewhere on the internet there is a post-war Triumph advertising movie showing some of the details of the frame and engine construction, as well as other shop scenes intended to show off the quality of the operation & products.

john.k

Diamond

- Joined

- Dec 21, 2012

- Location

- Brisbane Qld Australia

Ive seen that film years ago....unfortunately then it was degraded by videotape copying....Id like to see the original B&W film.,or a nice clear copy......Think it was one of the Geoff Duke series.

Limy Sami

Diamond

- Joined

- Jan 7, 2007

- Location

- Norfolk, UK

Some would say (not me  ) the quality and technology hasn't improved since then.

) the quality and technology hasn't improved since then.

) the quality and technology hasn't improved since then.

) the quality and technology hasn't improved since then.ramsay1

Titanium

- Joined

- Aug 19, 2003

- Location

- port allen, louisiana usa

Had one - what a disaster. It would either crap out because of the disintegrating cork float - or the amazingly wimpy cam gears lost another tooth or so.

5 bucks from the neighbor when I was 15. Got to learn how to relace a wheel - in order to get rid of the 21" clincher that was on the back.

Darn and here I thought the two shovelheads I had were bad.. Cheers; Ramsay 1

johnoder

Diamond

- Joined

- Jul 16, 2004

- Location

- Houston, TX USA

Lets just say the neighbor's 20 year later 74 flat tracker was lots more of a "motorsickle" which is what they were universally referred to in 1955 Central Texas

Being a flat tracker it had no brakes, but did have a mag - and since it leaned against his garage - it was always ready for a blast down North Nineteenth

Being a flat tracker it had no brakes, but did have a mag - and since it leaned against his garage - it was always ready for a blast down North Nineteenth

john.k

Diamond

- Joined

- Dec 21, 2012

- Location

- Brisbane Qld Australia

The cam gear was a weak point ,but didnt fail on magneto engines ,only when called on to drive the complex Remy generator/distributor setup on the electric model ...Mine being the "colonial model" electrics wernt deemed necessary ,or affordable.....I might add ,I recoed the American Bosch magneto when I was about 16 years old ,and its not needed to be touched since......IMHO ,Harley never improved on the 74" pocket valve engine ,and only went to the flathead for styling reasons (lower tank profile).....Its said the failure rate casting the pocket valve cylinders was high too.........As is well known ,the flathead 74 V model was a disaster ,and very nearly sent the company broke ....the pocket valve was so much better...It was the 45" and the singles that kept them going.

9100

Diamond

- Joined

- Nov 1, 2004

- Location

- Webster Groves, MO

As a card carrying Indian rider, I still have had the opportunity to ride several JDs. The hottest one was a flat tracker that was owned by a dealer. No gearbox, no brakes, and no stand. It was a crew served bike, needing someone to push start it and when you were finished, to slip the rear stand on. The stand pivots on a couple of studs with bolts to hold it in place. They left the bolts out and sprung the U shaped stand ends apart to unhook it. To start, the rider kept the bike standing upright while the pushers got ready and held the compression release open until they got up enough speed, then releasing it to start it firing. The gearbox was a housing with one shaft from one side to the other and a sprocket on each end, no clutch, no brakes. The Bowden wire throttle twist grip needed more twist to go from idle to full power than I could manage, so on each straight on the Davenport, IA fairgrounds track required twisting as far as I could, then changing my grip and giving it another twist. Shutdown was the reverse. An old bike and midget racer told me that they wouldn't allow brakes for fear of someone slowing suddenly and causing a pileup. To stop, you held the compression release open, timing it to come to a stop in front of the pit crew who reinstalled the stand. It sure did go, though. It also had an emergency killer, a pair of regular magneto points mounted on the handlebars. When closed, they grounded the the magneto points. They had a piece of insulation slipped between them tied to a lanyard on the rider's wrist. If he departed, they shut the engine down, important since the Bowden throttle wasn't spring loaded to idle and the bike could wind up on it's side with the engine destroying itself.

The carburetor float was a shellaced cork ring, very fragile and cannot handle ethanol because it dissolves the shellac and the cork swells. Fortunately someone makes a replacement of a very light plastic, known as a "Rubber Ducky".

I believe Harley and Indian both added front brakes in 1929 or 30. A lot of people were afraid of them. I have come to a stop with the rear wheel locked, still upright because the natural tendency is for the drag to hold the bike straight. If you lock up a front wheel, your chances are poor. The 1930 Indian brochure brags that their new two wheel brakes have brought the bike to a dead stop from 60 miles an hour in 12 seconds. My '30 Indian was lots of fun to ride, but trying to navigate heavy traffic required a death wish.

As John says, stock JDs are going machines but not so hot on stopping. By 1940, when the bike in my avatar, Indian had brought the front brakes up to reasonable utility and I ride in city traffic all the time.

Bill

The carburetor float was a shellaced cork ring, very fragile and cannot handle ethanol because it dissolves the shellac and the cork swells. Fortunately someone makes a replacement of a very light plastic, known as a "Rubber Ducky".

I believe Harley and Indian both added front brakes in 1929 or 30. A lot of people were afraid of them. I have come to a stop with the rear wheel locked, still upright because the natural tendency is for the drag to hold the bike straight. If you lock up a front wheel, your chances are poor. The 1930 Indian brochure brags that their new two wheel brakes have brought the bike to a dead stop from 60 miles an hour in 12 seconds. My '30 Indian was lots of fun to ride, but trying to navigate heavy traffic required a death wish.

As John says, stock JDs are going machines but not so hot on stopping. By 1940, when the bike in my avatar, Indian had brought the front brakes up to reasonable utility and I ride in city traffic all the time.

Bill

john.k

Diamond

- Joined

- Dec 21, 2012

- Location

- Brisbane Qld Australia

The ultimate pocket valve is the 1929 JDH with the twin cam motor and forged steel forks.And a front brake from the factory..And the ultimate 1920s Harley is one of the 8 valve motors.Something not generally known is HD got Harry Ricardo in England to design the new 350 motors in 1923 ,and at the same time he revised the finning on the new 74" to improve cooling.The 74 is the best looking of the pocket valve engines (pictured at the start of this) ....Later the 350 cylinder design was revised a bit for the new 45 in 1929.

Limy Sami

Diamond

- Joined

- Jan 7, 2007

- Location

- Norfolk, UK

But it's still a Harley Davidson.

jim rozen

Diamond

- Joined

- Feb 26, 2004

- Location

- peekskill, NY

... the ultimate 1920s Harley is one of the 8 valve motors.

The *real* ultimate HD 8 valve motor:

YouTube

...but it's an Indian...

jim rozen

Diamond

- Joined

- Feb 26, 2004

- Location

- peekskill, NY

Greg Menke

Diamond

- Joined

- Feb 22, 2004

- Location

- Baltimore, MD, USA

Isn't there a sort-of yearly old motorcycle cannonball run? Not so much for speed, but just to keep the bikes running and make it; everything on secondary roads and rules for distances and how closely the bikes can group. That seems way cooler than putting big gas tanks in a modern car and presumably going to the bathroom in plastic bottles...

Similar threads

- Replies

- 4

- Views

- 2K

- Replies

- 9

- Views

- 341

- Replies

- 7

- Views

- 960

- Replies

- 17

- Views

- 1K