...in business since 1938...formerly of Brooklyn, New York...now of New Brunswick, New Jersey...

...click photo for full size...

...more info CLICK HERE ...

...click photo for full size...

...more info CLICK HERE ...

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

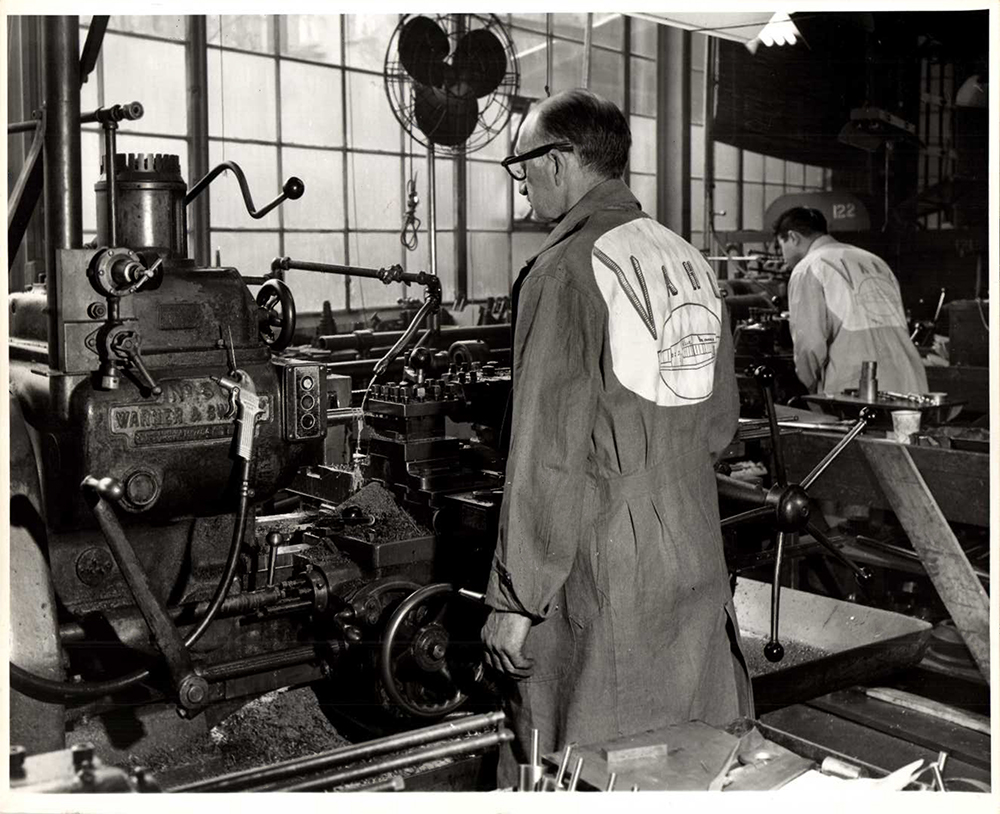

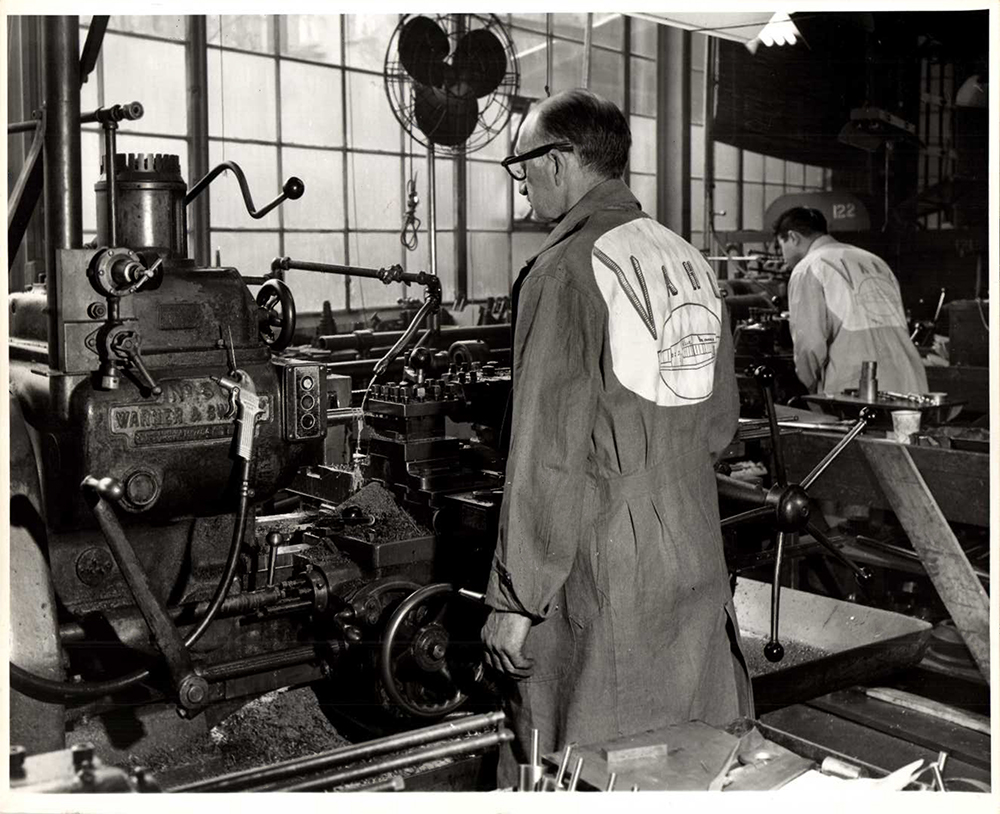

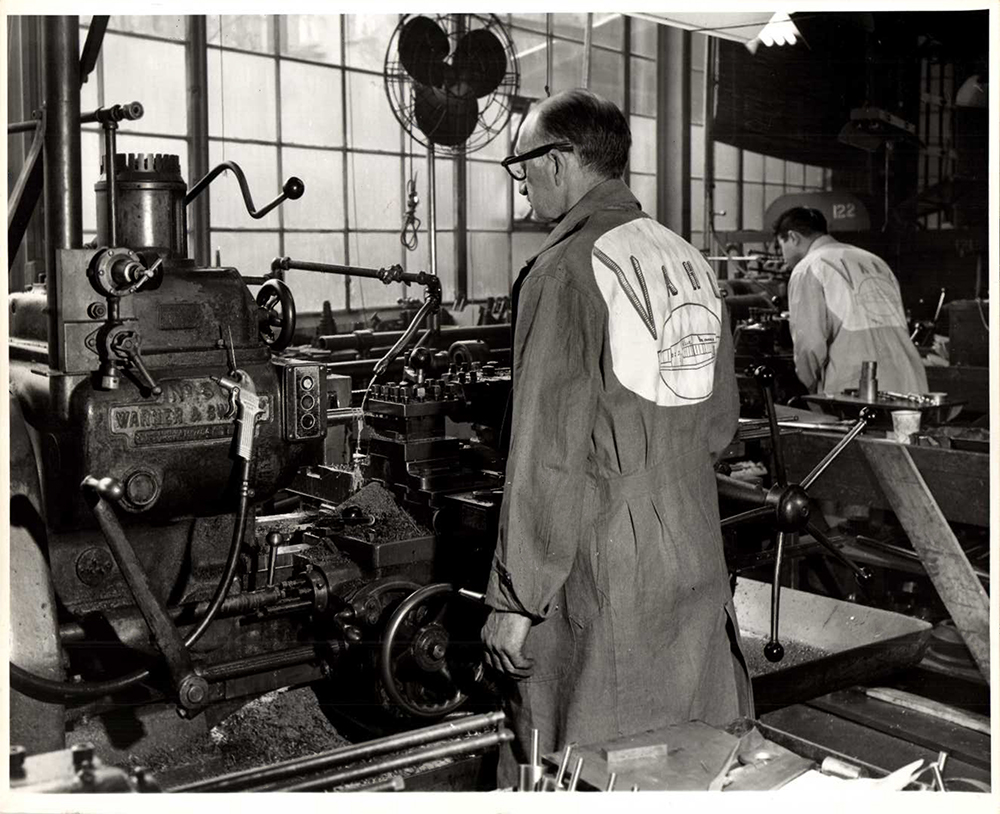

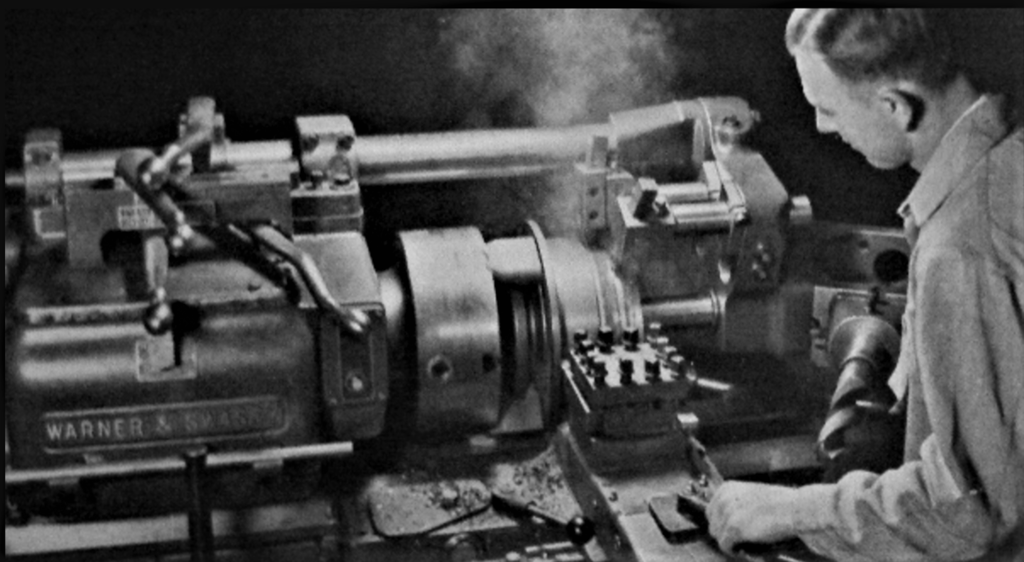

I have a nice #3. Nowhere the muscle of the machine in that photo - looks like a #4 or 5 - did 5's have that type of shifter? It was fun to stand back and watch the chips pour into the coolant pan while the power feed rammed an insert into the steel bar stock, and wait for the stop to trip the clutch out, no eagle eye needed on a dial or DRO.This is another machine I would like to run and own. Turret lathes have always fascinated me. I have all the parts and pieces to convert my little Logan 820 to a turret lathe, but it would of course not be anywhere near in the league of a WS.

Not necessarily, we did tens or less, even one part at a time, depending on the complexity. If something needed drilled and tapped it went right to the turret lathe, even only one part. I never sold it, just for that reason.I seem to recall reading that the set up of one could be pretty interesting, although time consuming. Running one on the other hand was drudgery, especially so when doing the same part for days on end.

A few years ago, I picked several Warner-Swasey publications/catalogs on turret lathes. The complexity of the numerous parts one could rapidly turn out was impressive indeed, and the various set ups were ingenious.

I seem to remember that the author of one of the books stated that the golden number range for a turret lathe was from around 100 or a little more, to about 1000 piece-parts. Below 100, it is more cost effective to use an engine lathe. When getting into the thousands, a dedicated automatic machine of some type was better.

This is another machine I would like to run and own. Turret lathes have always fascinated me. I have all the parts and pieces to convert my little Logan 820 to a turret lathe, but it would of course not be anywhere near in the league of a WS.

I seem to recall reading that the set up of one could be pretty interesting, although time consuming. Running one on the other hand was drudgery, especially so when doing the same part for days on end.

A few years ago, I picked several Warner-Swasey publications/catalogs on turret lathes. The complexity of the numerous parts one could rapidly turn out was impressive indeed, and the various set ups were ingenious.

I seem to remember that the author of one of the books stated that the golden number range for a turret lathe was from around 100 or a little more, to about 1000 piece-parts. Below 100, it is more cost effective to use an engine lathe. When getting into the thousands, a dedicated automatic machine of some type was better.

Oh yeah...forgot to add...Knee turners.

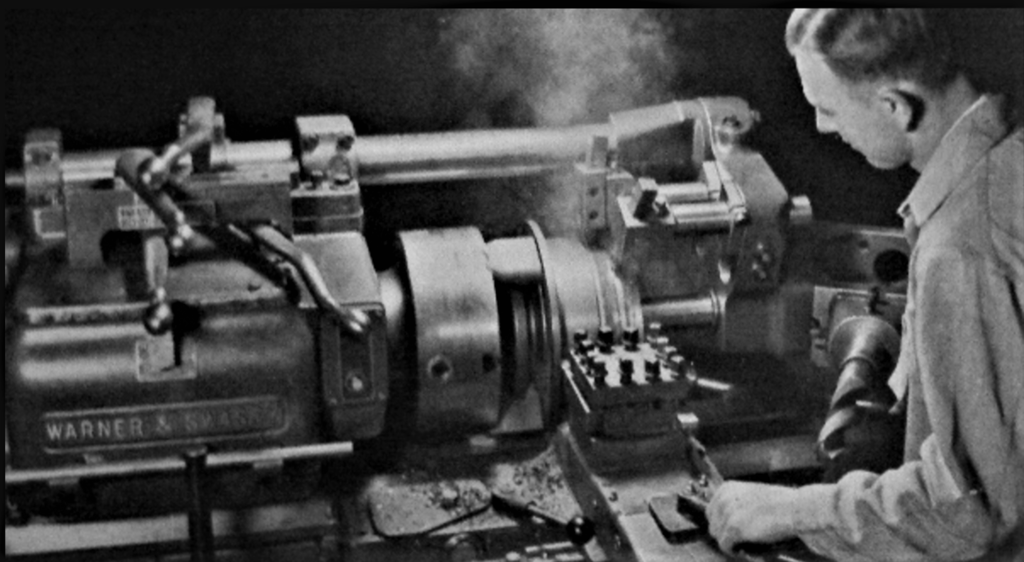

To totally change your thinking, notice how many turned diameters

are done from the turret using "Knee turners".

Not all O.D. turning is done on the crosslide, as in a standard engine lathe.

Those goofy looking turret attachments with 5 or so holes ?

They can hold a couple of knee turners, enabling (with one stroke

of the turret) cutting a couple of diameters at once.

Very good picture showing the 5 hole turret adapters, and (2) knee turners at work

Oh yeah...forgot to add...Knee turners.

To totally change your thinking, notice how many turned diameters

are done from the turret using "Knee turners".

Not all O.D. turning is done on the crosslide, as in a standard engine lathe.

......

...I never used to pay much attention to turret lathes...now I am fascinated by them...below is a photo from the W&S "Turret Lathe Operators Manual" that shows two outside diameter cuts and a boring cut being taken by the turret...while the cross slide takes another outside diameter cut...now THAT'S A MACHINE!...

.......even if at times all you felt you were was a chip shoveller

.......even if at times all you felt you were was a chip shoveller

Knee tools, box tools, hollow mills, balance turning tools, all ways to turn the OD from the turret.

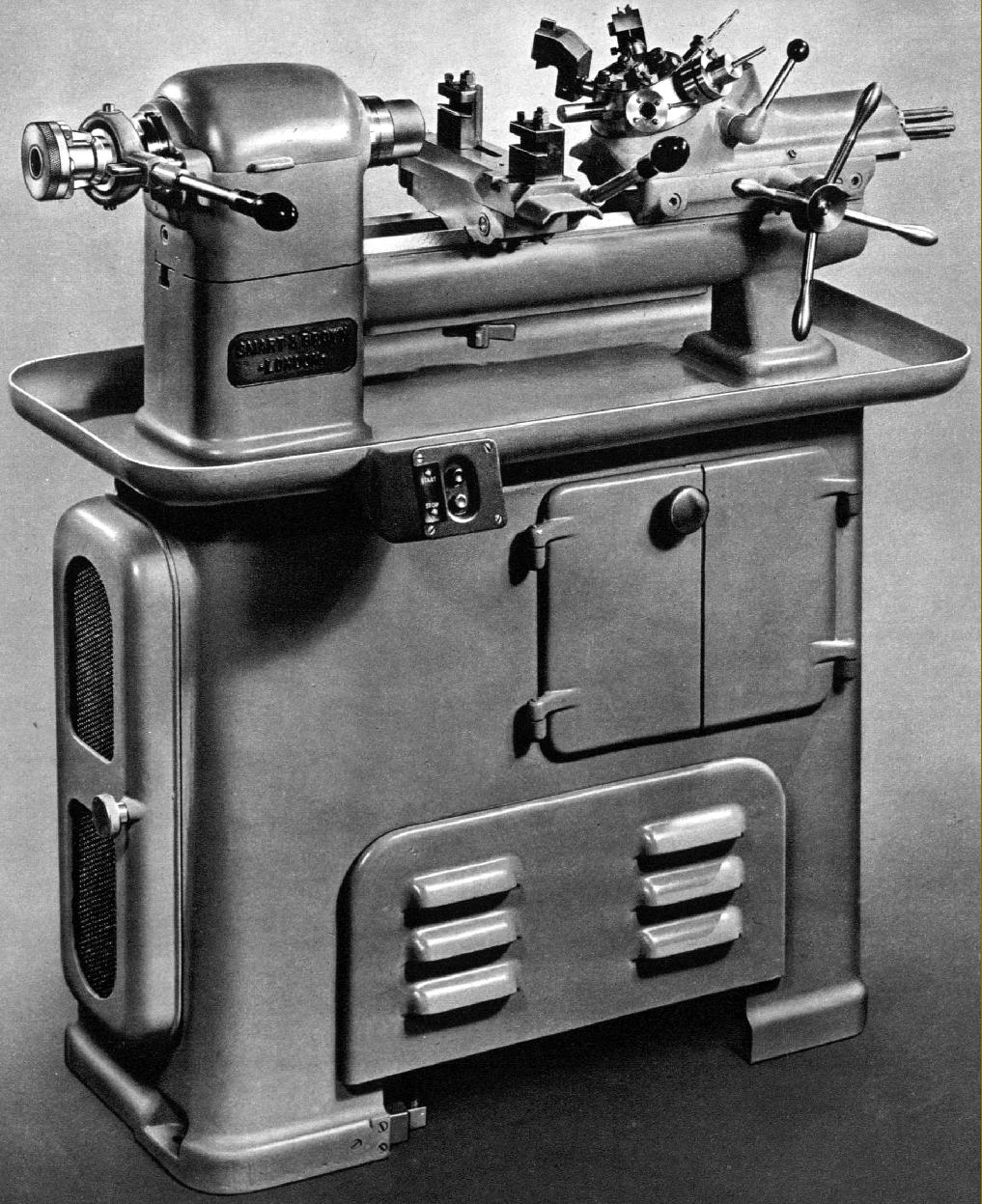

That's a real goody lathefan, like you I'm into turret lathes, I have a smart and brown in storage as I've no space.

But jobs like that were run day in day out - it's what the machines were built for, and back in the day I loved jobs up to say around 200 off, especially the bigger lumps like that.

Turrets aren't as set and forget as a lot think, on the sort of work in the pic you at least needed a good operator if not skilled man, there's a lot going on at once, and if you lose a tool edge and don't notice it, you can do a lot of damage, or at the very least time down for major resetting.

And the cross slide stops don't automatically index with the toolpost rotation or saddle movements, (well not in the UK anyway) and a bad operator not moving the stops when indexing can cause some unholy messes.

That said - especially when I was on bonus, setting up and running a job where I had say big drilling (1'' plus) and 3 or 4 tools on the turret on the turret really hossing it off to get the job done fast, was cool.......even if at times all you felt you were was a chip shoveller

...Sami...you need to get that Smart and Brown working...make some widgets and doohickeys for beer money...

Bear money? .....I could really use it to LIVE ON, but no room, 2 mills a 10'' long bed SB clone, shaper and pillar drill, bandsaw and several bench grinders and a bench, a filing cabinet plus tooling and stock in a 19-6 x 7-6 shop is a very tight squeeze ;eek: as it is, and no room to expand. .oh and the shop is fully shelved where ever possible.

PS My S&B is the late square head Model L with the single lever cut off slide and 3 station capstan handled turret - here ;- http://www.lathes.co.uk/smart-and-brown-model-L/

Notice

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.