How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

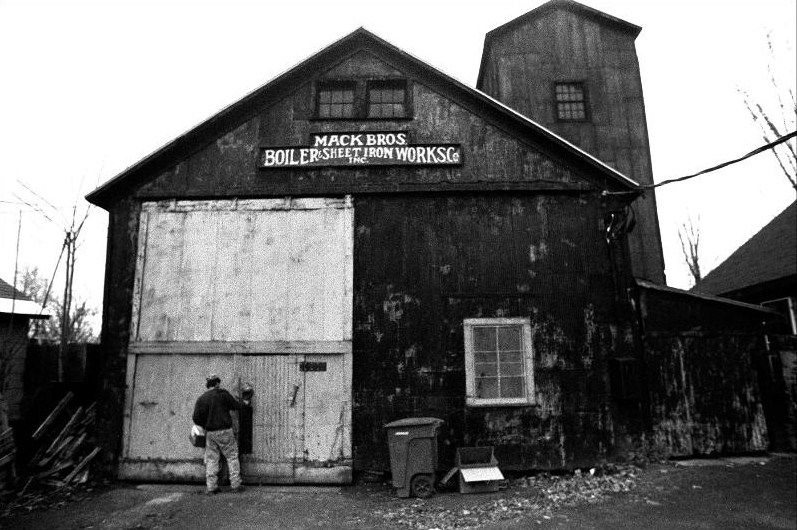

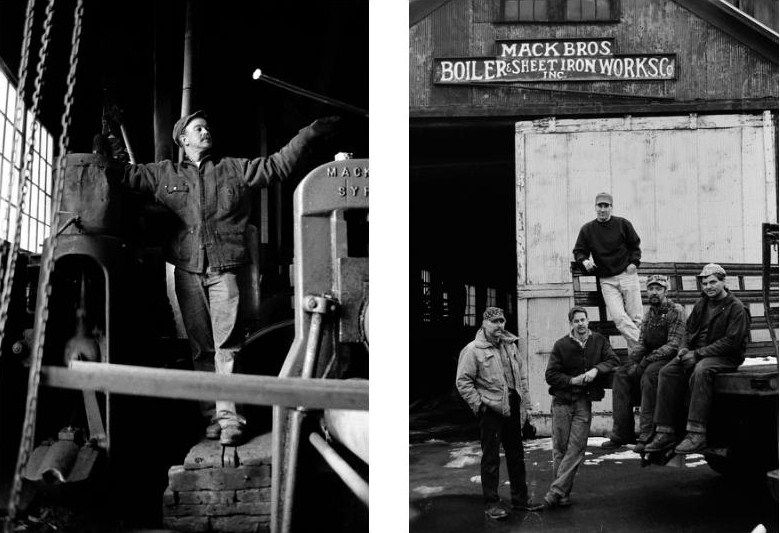

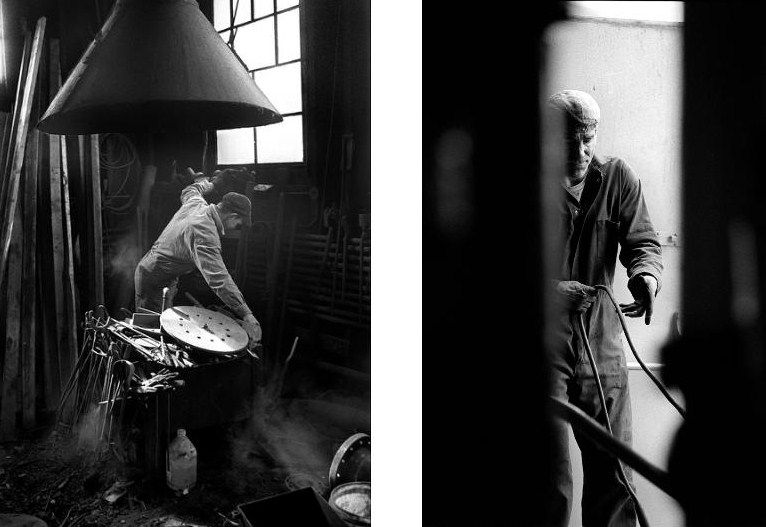

Photos...Mack Brothers Boiler and Sheet Iron Works...

- Thread starter lathefan

- Start date

- Replies 13

- Views 5,827

sable

Titanium

- Joined

- Feb 7, 2013

- Location

- midlands,UK

Cool pics Lathefan , this is recent right ? just a few things to give it away but could almost be 100 years ago like a lot of the others you have put on here.

Cool pics Lathefan , this is recent right ? just a few things to give it away but could almost be 100 years ago like a lot of the others you have put on here.

...not sure of the year...but it is recent...the plastic trash can in the first photo gives it away...

metalmaster10

Stainless

- Joined

- Apr 18, 2012

- Location

- Indiana, USA

Someone did a great job of capturing an "old" look an feel in those pics.

Other than the plastic trash can, modern lunchbox, and modern clothing of the guys on the truck, they could easily have passed for 1940...

Very cool!

Other than the plastic trash can, modern lunchbox, and modern clothing of the guys on the truck, they could easily have passed for 1940...

Very cool!

Joe Michaels

Diamond

- Joined

- Apr 3, 2004

- Location

- Shandaken, NY, USA

Mack Brothers Boiler and Sheet Iron Works has been in business since sometime in the late 1800's. They are still at it. When I designed the re-creation of the 1890 boiler plant at Hanford Mills, Mack Iron Works was able to understand what I wanted without a whole lot of additional explanation. They KNEW what a "flush front" Horizontal Return Tube boiler was, and they were able to take my drawings and produce riveted steel flue gas ducting (breeching) and a transition from narrow/rectangular to the round stack diameter. They also produced riveted Cor Ten (weathering steel that does not need painting) steel stack sections. When we erected the stack, Jim Huber, who is a great grandson of one of the Mack Brothers, was on hand. Jim Huber knew how to tension to stack guys (5/16" wire rope guys coming off the mid height and top of the stack). No turnbuckles. I had lucked into a set of wire rope grabs used by linemen at a yard sale. Jim Huber used them with a comealong to set the tension in the stack guys and then we socked up the "Crosby Clips".

When we first got the HRT into its setting, we planned to use a plain plate steel boiler setting front. This looked kind of poor, knowing that in 1890, when Erie City Iron Works furnished the original HRT to Hanford Mills, there was an ornate cast iron boiler front. Jim Huber dug around in the old archives (being polite) at the Mack Brothers shop. He found an original Erie City Iron Works "catalog cut" of the ornate cast iron boiler front that was right for the size/type of HRT we were re-creating at Hanford Mills. Jim Huber said the catalog was something his great grandfather saved, and we sent the catalog cut along with a dimensioned drawing of the as-built boiler setting to Strasburg RR. They made the patterns and had the castings poured for a replica boiler front that looked as it did in 1890.

When we got the plant in steam, Jim Huber arrived with his young son, wanting to show him what an oldtime boiler was about. Hopefully, the tradition will continue. Mack Brothers is a shop which has a genuine interest in keeping the old boilermaking skills alive. They will work on historic boilers as well as modern ones. They did excellent plate forming or "development" work for us at Hanford Mills, laying out the brake lines on the sheets and forming them into the transition section in the classic way. A few years later, some "compensation" for the dome hole on a locomotive boiler was needed. The existing boiler worked fine, but under the new FRA regulations, based on ASME boiler code formulas, there was inadequate compensation (reinforcement or doubler plate) around the dome hole. Mack came on site to the engine house, measured up the job and took it from there. They formed the sheets, fitted them to the boiler to saddle around the dome, and welded out using a combination of SMAW and GFCAW since a lot of weld was needed. They had weld procedures qualified for this kind of boiler welding, and had welders qualified to those procedures. They came on site and hit it running, and did a fine job.

Mack Brothers is an ASME code shop, and will work on anything that they can handle in their shop. Jim Huber told me the steam engine driving the plate rolls was secondhand, and came from some marine application, though no one amongst the living knows where or what it came from. Mack does a lot of work on packaged heating boilers (mostly "dry back" Scotch boilers such as Cleaver Brooks), and will do jobs like replacing furnaces or retubing.

There is supposed to be a similar boiler shop up in Punxsutawny, PA, also old as the hills and willing to work on riveted and fire tube boiler work. I forget the name of that shop. Mack, being geographically closer, is the one we used for the job at Hanford Mills. The good part is that Jim Huber is relatively young, as are the other boilermakers in Mack's shop. There is a good chance of a continuum, since the men at Mack Brothers are relatively young, and Mack seems to have found a niche with a fairly steady supply of "modern jobs" such as packed boilers in hospitals, industrial plants, and schools, and will work on historic boilers as well.

When we first got the HRT into its setting, we planned to use a plain plate steel boiler setting front. This looked kind of poor, knowing that in 1890, when Erie City Iron Works furnished the original HRT to Hanford Mills, there was an ornate cast iron boiler front. Jim Huber dug around in the old archives (being polite) at the Mack Brothers shop. He found an original Erie City Iron Works "catalog cut" of the ornate cast iron boiler front that was right for the size/type of HRT we were re-creating at Hanford Mills. Jim Huber said the catalog was something his great grandfather saved, and we sent the catalog cut along with a dimensioned drawing of the as-built boiler setting to Strasburg RR. They made the patterns and had the castings poured for a replica boiler front that looked as it did in 1890.

When we got the plant in steam, Jim Huber arrived with his young son, wanting to show him what an oldtime boiler was about. Hopefully, the tradition will continue. Mack Brothers is a shop which has a genuine interest in keeping the old boilermaking skills alive. They will work on historic boilers as well as modern ones. They did excellent plate forming or "development" work for us at Hanford Mills, laying out the brake lines on the sheets and forming them into the transition section in the classic way. A few years later, some "compensation" for the dome hole on a locomotive boiler was needed. The existing boiler worked fine, but under the new FRA regulations, based on ASME boiler code formulas, there was inadequate compensation (reinforcement or doubler plate) around the dome hole. Mack came on site to the engine house, measured up the job and took it from there. They formed the sheets, fitted them to the boiler to saddle around the dome, and welded out using a combination of SMAW and GFCAW since a lot of weld was needed. They had weld procedures qualified for this kind of boiler welding, and had welders qualified to those procedures. They came on site and hit it running, and did a fine job.

Mack Brothers is an ASME code shop, and will work on anything that they can handle in their shop. Jim Huber told me the steam engine driving the plate rolls was secondhand, and came from some marine application, though no one amongst the living knows where or what it came from. Mack does a lot of work on packaged heating boilers (mostly "dry back" Scotch boilers such as Cleaver Brooks), and will do jobs like replacing furnaces or retubing.

There is supposed to be a similar boiler shop up in Punxsutawny, PA, also old as the hills and willing to work on riveted and fire tube boiler work. I forget the name of that shop. Mack, being geographically closer, is the one we used for the job at Hanford Mills. The good part is that Jim Huber is relatively young, as are the other boilermakers in Mack's shop. There is a good chance of a continuum, since the men at Mack Brothers are relatively young, and Mack seems to have found a niche with a fairly steady supply of "modern jobs" such as packed boilers in hospitals, industrial plants, and schools, and will work on historic boilers as well.

Greg Menke

Diamond

- Joined

- Feb 22, 2004

- Location

- Baltimore, MD, USA

IIRC and if the guy there was telling me the truth the Boothbay Railroad Co built the 1st steam loco boiler in Maine in about 100 years, albeit small scale but legit. It was under pressure test when I stopped by a while back. They take in outside work as well. Its a great place to stop by, get a ride on one of their trains and go schmooze in the shop for a bit.

IIRC and if the guy there was telling me the truth the Boothbay Railroad Co built the 1st steam loco boiler in Maine in about 100 years, albeit small scale but legit. It was under pressure test when I stopped by a while back. They take in outside work as well. Its a great place to stop by, get a ride on one of their trains and go schmooze in the shop for a bit.

dkmc

Diamond

- Joined

- Jan 13, 2002

Cool...where is that?

That loco looks to be about 24" or 36" gauge

EDT

I read closer.....very cool

Be great fun to visit there!

That loco looks to be about 24" or 36" gauge

EDT

I read closer.....very cool

Be great fun to visit there!

Last edited:

Iron Man Retired

Banned

- Joined

- Jan 4, 2014

- Location

- Cullman, AL/New Orleans, LA

My hands looked like the photo of hands/hammer for 55 years!!! I couldn't get near my wife's pantyhouse, ha... Nor much more around her body

clothed or not, ha

clothed or not, ha

clothed or not, ha

clothed or not, ha

surplusjohn

Diamond

- Joined

- Apr 11, 2002

- Location

- Syracuse, NY USA

Mack Brothers is a block away from me, I just walked by them at lunch and yes those photos are recent, but now building has read clapboard siding on it. . to bad Utica Steam Engine is gone! that was something out of the old time, for sure. Do you know the photographer? looks like Sylvia DeSwan

Last edited:

Marty Feldman

Titanium

- Joined

- Feb 21, 2005

- Location

- Falmouth, Maine

The Boothbay site in Maine is Boothbay Railway Village, railwayvillage.org.

-Marty-

-Marty-

Joe Michaels

Diamond

- Joined

- Apr 3, 2004

- Location

- Shandaken, NY, USA

In the past few months, I was retained to do the engineering for the repairs on Arcade & Attica RR's locomotive number 18's boiler. 15 years earlier, I had run a set of boiler calculations and filed the Form 4 (boiler registration document) and Form 19's (boiler alteration and repair documents) with the US Federal RR Administration (FRA).

When the tubes reached the end of their allowable time (based on days of service, meaning whenever there is a fire in the boiler), the locomotive came up for inspection and tube replacement. I got a call from the A & A RR to come up and take a look at the firebox. The FRA had inspected the firebox and due to the amount of repairs and repairs-on-repairs consisting of patching, pad welding, and new cracks in some of the firebox sheets, FRA had condemned the firebox in its entirety. My inspection confirmed this. I recommended Mack Brothers Boiler Works to handle the repairs and making of a new firebox. I went up to the A & A RR in February and Jimmy Hueber, the owner of Mack Brother, met with us at the A & A RR's engine house. We had had a conference call with FRA previously, and I had suggested using welded construction for a firebox replacement, something I had done on Steamtown's number 26. With a "keyhole" shaped firebox, using welded construction allows the firebox to be "built" inside the "wrapper" of the boiler. In the days of riveted construction, replacing this style firebox would have meant at least taking the backhead off the boiler. FRA was fine with welded construction for the new firebox but wanted the sheets (any plate steel part going into a firetube boiler is referred to as a "sheet", even if formed into curved sections) to be flanged rather than simply making the corners with welded seams.

We put a tentative plan together with Mack Brothers: the boiler on Locomotive 18 will be transported to Syracuse on a low-boy, and Mack Brother shop will work on it there. Mack Brothers no longer flanges boiler sheets, so that part of the job will be subbed out. Mack Brothers also knows that it no longer pays to layout and trepan or drill holes in a tube sheet, so gives that out to CNC waterjet cutting shops.

This past Wednesday, my buddy and I drove up to Mack Brothers for a meeting with A & A RR's people to discuss the job. It was my first visit to Mack Brothers' shop. Jimmy Hueber gave us quite the tour. It is a working time capsule that kept with the times. Modern welding equipment is in use, including MIG and TIG, surrounded by the original boiler shop. The office is a modest frame house that one of the shop's founders had lived in back in the 1800's. The office walls are hung with framed working drawings done by the founders of the shop in India Ink. We saw quite a similarity between their drawings and my own engineering drawings. Boilers of all sorts of designs were on those drawings, and Jimmy Hueber said they have plenty more in the "flat files", all traced on linen in India Ink. The shop itself held machinery I had only seen here on this 'board or in old books. A post-mounted radial drill, with the drill head on a kind of jib swung off a column in the shop, driven by open gearing from lineshafting. The old lineshafting and its motor are all operational. That post-mounted radial drill was used to drill holes in boiler sheets and could reach across a complete boiler sheet to reach holes for rivets or staybolts. Jimmy Hueber fired up the "new" shop air compressor- a big one cylinder reciprocating Chicago-Pneumatic compressor installed in 1943 since the shop was doing defense work at the time. The compressor discharged into a large riveted vertical air receiver which Jimmy said his grandfather had designed and built. he pointed out a "mistake" on the receiver: his grandfather had made both barrel courses the same diameter, instead of one telescoping into the other. To solve this problem, the end of one course had been swedged down in outer diameter to slip into the other . It meant "scarfing the sheets" on the long seam of the course which was being swedged down. It was a neat piece of boilermaking in its own right. When air pressure was up, Jimmy Hueber ran the plate rolls for us- the compressed air being needed to run the steam engine that drives the rolls. The rolls have the Mack Brothers name cast into the roll stands, and the engine is a "twin" cylinder (no compounding) with Stephenson's link motion. Jimmy Hueber had the rolls running full ahead and without shutting off air, moved the reverse lever to the other end of the quadrant, putting the rolls into "emergency astern". He said those rolls have handled up to 3" thick plate.

The shop was a time capsule, but a working one. Jimmy's nephew, a man in maybe his '30's is active in the business, which is a good thing- seeing younger people carrying it on.

We figured out how the job will be done, and Mack Brothers will be doing the work. The flanging will be subbed out, and the furnishing of the flexible staybolts will be subbed out. Jimmy showed us the toolroom- off the office. It is a storehouse of everything a boilermaker working on riveted firetube boilers could ever need. I saw staybolt taps, and I saw the tapered-thread "boiler taps" for putting in studbolts into the sheets of a boiler. There were riveting guns and rivet snaps and rivet busters stacked on a shelf like cordwood. More stacks of tube rollers, and what the old boilermakers called "banjo's" (gear drives to run a tube roller inside a tight place like in a mud drum or similar). Jimmy Hueber is a rare man in this day and age, and he takes a genuine pride and interest in carrying on his family's heritage in boiler work. Like me, he does not use CAD, and like me, has a drawing table with a "drafting machine" on it. We joked about the trials and tribulations we went through as youngsters learning to trace a drawing in ink and getting the fatal ink blotch when the ruling pen caught on the thread of the linen tracing cloth.

I had my boiler calculations with me for the Arcade and Attica Boiler, and those calculations run about 100 pages, all done longhand. We went over them, as we needed to know developed stresses and loadings for staybolts and similar. I know Jimmy Hueber got a kick out of seeing the calculations and remarked when we were on "page 68" about the sheer volume of calculations needed to figure the minimum required thicknesses and maximum allowable working pressure in a Locomotive Boiler. It was a great visit, and I am glad to be able to send a job to the Mack Brothers Boiler and Sheet Iron Works.

Syracuse, NY, like so many other cities, was once a thriving manufacturing town. Within line of sight of Mack Brothers is the former Dietz lantern factory. Dietz is history, but the building was repainted with the old lettering with the Dietz logo and name. Dietz lanterns were once found all over, on farms, jobsites, and railroads. They were exported all over the world. Jimmy Hueber said they used to maintain the boilers in the old Dietz plant when it was up and running, but like so much of the industry in Syracuse, is long gone. Mack Brothers is a holdout, and moved with the times and survives, blending old with the new.

I call myself a stubborn dinosaur, and stepping into Jimmy Hueber's office and then the shop, I felt like I was coming to a place I belonged and knew.

When the tubes reached the end of their allowable time (based on days of service, meaning whenever there is a fire in the boiler), the locomotive came up for inspection and tube replacement. I got a call from the A & A RR to come up and take a look at the firebox. The FRA had inspected the firebox and due to the amount of repairs and repairs-on-repairs consisting of patching, pad welding, and new cracks in some of the firebox sheets, FRA had condemned the firebox in its entirety. My inspection confirmed this. I recommended Mack Brothers Boiler Works to handle the repairs and making of a new firebox. I went up to the A & A RR in February and Jimmy Hueber, the owner of Mack Brother, met with us at the A & A RR's engine house. We had had a conference call with FRA previously, and I had suggested using welded construction for a firebox replacement, something I had done on Steamtown's number 26. With a "keyhole" shaped firebox, using welded construction allows the firebox to be "built" inside the "wrapper" of the boiler. In the days of riveted construction, replacing this style firebox would have meant at least taking the backhead off the boiler. FRA was fine with welded construction for the new firebox but wanted the sheets (any plate steel part going into a firetube boiler is referred to as a "sheet", even if formed into curved sections) to be flanged rather than simply making the corners with welded seams.

We put a tentative plan together with Mack Brothers: the boiler on Locomotive 18 will be transported to Syracuse on a low-boy, and Mack Brother shop will work on it there. Mack Brothers no longer flanges boiler sheets, so that part of the job will be subbed out. Mack Brothers also knows that it no longer pays to layout and trepan or drill holes in a tube sheet, so gives that out to CNC waterjet cutting shops.

This past Wednesday, my buddy and I drove up to Mack Brothers for a meeting with A & A RR's people to discuss the job. It was my first visit to Mack Brothers' shop. Jimmy Hueber gave us quite the tour. It is a working time capsule that kept with the times. Modern welding equipment is in use, including MIG and TIG, surrounded by the original boiler shop. The office is a modest frame house that one of the shop's founders had lived in back in the 1800's. The office walls are hung with framed working drawings done by the founders of the shop in India Ink. We saw quite a similarity between their drawings and my own engineering drawings. Boilers of all sorts of designs were on those drawings, and Jimmy Hueber said they have plenty more in the "flat files", all traced on linen in India Ink. The shop itself held machinery I had only seen here on this 'board or in old books. A post-mounted radial drill, with the drill head on a kind of jib swung off a column in the shop, driven by open gearing from lineshafting. The old lineshafting and its motor are all operational. That post-mounted radial drill was used to drill holes in boiler sheets and could reach across a complete boiler sheet to reach holes for rivets or staybolts. Jimmy Hueber fired up the "new" shop air compressor- a big one cylinder reciprocating Chicago-Pneumatic compressor installed in 1943 since the shop was doing defense work at the time. The compressor discharged into a large riveted vertical air receiver which Jimmy said his grandfather had designed and built. he pointed out a "mistake" on the receiver: his grandfather had made both barrel courses the same diameter, instead of one telescoping into the other. To solve this problem, the end of one course had been swedged down in outer diameter to slip into the other . It meant "scarfing the sheets" on the long seam of the course which was being swedged down. It was a neat piece of boilermaking in its own right. When air pressure was up, Jimmy Hueber ran the plate rolls for us- the compressed air being needed to run the steam engine that drives the rolls. The rolls have the Mack Brothers name cast into the roll stands, and the engine is a "twin" cylinder (no compounding) with Stephenson's link motion. Jimmy Hueber had the rolls running full ahead and without shutting off air, moved the reverse lever to the other end of the quadrant, putting the rolls into "emergency astern". He said those rolls have handled up to 3" thick plate.

The shop was a time capsule, but a working one. Jimmy's nephew, a man in maybe his '30's is active in the business, which is a good thing- seeing younger people carrying it on.

We figured out how the job will be done, and Mack Brothers will be doing the work. The flanging will be subbed out, and the furnishing of the flexible staybolts will be subbed out. Jimmy showed us the toolroom- off the office. It is a storehouse of everything a boilermaker working on riveted firetube boilers could ever need. I saw staybolt taps, and I saw the tapered-thread "boiler taps" for putting in studbolts into the sheets of a boiler. There were riveting guns and rivet snaps and rivet busters stacked on a shelf like cordwood. More stacks of tube rollers, and what the old boilermakers called "banjo's" (gear drives to run a tube roller inside a tight place like in a mud drum or similar). Jimmy Hueber is a rare man in this day and age, and he takes a genuine pride and interest in carrying on his family's heritage in boiler work. Like me, he does not use CAD, and like me, has a drawing table with a "drafting machine" on it. We joked about the trials and tribulations we went through as youngsters learning to trace a drawing in ink and getting the fatal ink blotch when the ruling pen caught on the thread of the linen tracing cloth.

I had my boiler calculations with me for the Arcade and Attica Boiler, and those calculations run about 100 pages, all done longhand. We went over them, as we needed to know developed stresses and loadings for staybolts and similar. I know Jimmy Hueber got a kick out of seeing the calculations and remarked when we were on "page 68" about the sheer volume of calculations needed to figure the minimum required thicknesses and maximum allowable working pressure in a Locomotive Boiler. It was a great visit, and I am glad to be able to send a job to the Mack Brothers Boiler and Sheet Iron Works.

Syracuse, NY, like so many other cities, was once a thriving manufacturing town. Within line of sight of Mack Brothers is the former Dietz lantern factory. Dietz is history, but the building was repainted with the old lettering with the Dietz logo and name. Dietz lanterns were once found all over, on farms, jobsites, and railroads. They were exported all over the world. Jimmy Hueber said they used to maintain the boilers in the old Dietz plant when it was up and running, but like so much of the industry in Syracuse, is long gone. Mack Brothers is a holdout, and moved with the times and survives, blending old with the new.

I call myself a stubborn dinosaur, and stepping into Jimmy Hueber's office and then the shop, I felt like I was coming to a place I belonged and knew.

surplusjohn

Diamond

- Joined

- Apr 11, 2002

- Location

- Syracuse, NY USA

Sorry i missed you, my day job is three blocks one way and my studio is two blocks the other way.

Within a few blocks were a john deere plant, rockwell, porter cable, gm , carrier, new process gear, smith typewriters, lipe rollway, fisher guide, engelburg , bradford forges, kane and roach. Etc etc

Within a few blocks were a john deere plant, rockwell, porter cable, gm , carrier, new process gear, smith typewriters, lipe rollway, fisher guide, engelburg , bradford forges, kane and roach. Etc etc

Joe Michaels

Diamond

- Joined

- Apr 3, 2004

- Location

- Shandaken, NY, USA

Surplusjohn:

I am sure that once the boiler work for the Arcade & Attica RR gets going, I will be back up at Mack Brothers. We can certainly try to get together when I am back up at Mack Brothers Boiler Works. The locomotive boiler is more than Mack Brothers' shop bridge cranes can handle. As a result, Jim Hueber is going to have the boiler delivered to another shop in Fulton, NY with sufficient bridge crane capacity to handle the boiler. The firebox will be fabricated and fitted up in the old Syracuse shop, then taken in pieces up to the Fulton shop for installation in the boiler.

At the present time, the time frame is kind of vague, but Arcade and Attica RR will be starting the removal of the boiler from the locomotive's frame in the near future, followed by its delivery to Fulton, NY. Once at Fulton, NY, boilermakers from the Mack shop will be travelling to Fulton to work on the boiler. It promises to be an interesting job, and may take a few months from the time the old firebox is pulled out of the boiler. The old firebox will be taken out in pieces, with index marks and dogs or clip angles welded to the pieces. This will allow the old firebox inner door sheet and rear tube sheet to be reassembled for purposes of making the new sheets.

Syracuse, NY, is like so many other cities that once had manufacturing industries. I spent a good bit of time in Utica, NY when we were working up at Hinkley Dam on a new hydroelectric project. In my off hours, living out of a motel room, I explored Utica and saw quite a number of large manufacturing plants sitting vacant and often derelict. I never explored Syracuse, but from what little I know about Syracuse, it had even more industry than Utica. Don't forget the Franklin air-cooled cars- which survived quite a bit longer after car manufacturing ceased by making aircraft engines. There was also Bradley- the manufacturer of forging hammers- in Syracuse. Mack Brothers' shop has a coal fired forge hearth and a Bradley "helve" hammer ( a kind of power hammer that uses a hardwood beam to swing the actual hammer).

In driving into and out of Syracuse on I 81 and I 690, I was astonished at the size of the "Upstate Medical Center" complex. From the looks of it and the demise of manufacturing, I would think the medical center may be one of the major employers in Syracuse. The medical center has a sizeable boiler plant with two separate buildings and brick smokestacks. I'd be interested to know if that plant produces electric power, or is just providing heating steam and chilled water.

Years ago, back when I was working for the NY Power Authority, some of our people used to travel up to the powerplants at Massena, NY or Niagara Falls. Many of those trips included a stop at the Dinosaur Barbecue. I never made it to the Dinosaur Barbecue, but was constantly being told to pay it a visit since I ride heavy motorcycles and won't say no to a good rack of barbecued ribs or pulled pork. Apparently, the down-and-out bikers who started the Dinosaur Barbecue hit on a good thing and prospered with it. About the closest I've come to the Dinosaur Barbecue is buying some of their sauce in the local supermarket. Great sauce, BTW. At the rate Syracuse is going, it would be a kick in the ass if the medical center and the Dinosaur Barbecue were the leading economic engines !

I will look forward to getting together with you at some future visit to Mack Brothers. PM me your contact data and I will keep it handy.

Best regards-

Joe Michaels

I am sure that once the boiler work for the Arcade & Attica RR gets going, I will be back up at Mack Brothers. We can certainly try to get together when I am back up at Mack Brothers Boiler Works. The locomotive boiler is more than Mack Brothers' shop bridge cranes can handle. As a result, Jim Hueber is going to have the boiler delivered to another shop in Fulton, NY with sufficient bridge crane capacity to handle the boiler. The firebox will be fabricated and fitted up in the old Syracuse shop, then taken in pieces up to the Fulton shop for installation in the boiler.

At the present time, the time frame is kind of vague, but Arcade and Attica RR will be starting the removal of the boiler from the locomotive's frame in the near future, followed by its delivery to Fulton, NY. Once at Fulton, NY, boilermakers from the Mack shop will be travelling to Fulton to work on the boiler. It promises to be an interesting job, and may take a few months from the time the old firebox is pulled out of the boiler. The old firebox will be taken out in pieces, with index marks and dogs or clip angles welded to the pieces. This will allow the old firebox inner door sheet and rear tube sheet to be reassembled for purposes of making the new sheets.

Syracuse, NY, is like so many other cities that once had manufacturing industries. I spent a good bit of time in Utica, NY when we were working up at Hinkley Dam on a new hydroelectric project. In my off hours, living out of a motel room, I explored Utica and saw quite a number of large manufacturing plants sitting vacant and often derelict. I never explored Syracuse, but from what little I know about Syracuse, it had even more industry than Utica. Don't forget the Franklin air-cooled cars- which survived quite a bit longer after car manufacturing ceased by making aircraft engines. There was also Bradley- the manufacturer of forging hammers- in Syracuse. Mack Brothers' shop has a coal fired forge hearth and a Bradley "helve" hammer ( a kind of power hammer that uses a hardwood beam to swing the actual hammer).

In driving into and out of Syracuse on I 81 and I 690, I was astonished at the size of the "Upstate Medical Center" complex. From the looks of it and the demise of manufacturing, I would think the medical center may be one of the major employers in Syracuse. The medical center has a sizeable boiler plant with two separate buildings and brick smokestacks. I'd be interested to know if that plant produces electric power, or is just providing heating steam and chilled water.

Years ago, back when I was working for the NY Power Authority, some of our people used to travel up to the powerplants at Massena, NY or Niagara Falls. Many of those trips included a stop at the Dinosaur Barbecue. I never made it to the Dinosaur Barbecue, but was constantly being told to pay it a visit since I ride heavy motorcycles and won't say no to a good rack of barbecued ribs or pulled pork. Apparently, the down-and-out bikers who started the Dinosaur Barbecue hit on a good thing and prospered with it. About the closest I've come to the Dinosaur Barbecue is buying some of their sauce in the local supermarket. Great sauce, BTW. At the rate Syracuse is going, it would be a kick in the ass if the medical center and the Dinosaur Barbecue were the leading economic engines !

I will look forward to getting together with you at some future visit to Mack Brothers. PM me your contact data and I will keep it handy.

Best regards-

Joe Michaels

Similar threads

- Replies

- 2

- Views

- 236

- Replies

- 3

- Views

- 227

- Replies

- 7

- Views

- 695