matt_isserstedt

Diamond

- Joined

- Dec 15, 2003

- Location

- suburbs of Ann Arbor, MI, USA

Sooo

I'm headed down the road of getting the planer going 24x72 table, Putnam. Need some press brake tooling...

I think I want to use a 1/2" toolbit but don't have the proper holder.

I like the Armstrong 401 design but that's basically for a 3/8" sq toolbit.

I can handle designing it to work, but I have a question about the structure.

The Armstrong 401 has a bulbous head on a "flat bar" shaft. I can see why they wanted to conserve material with either a casting or forging.

I would propose to make it out of a heavy square bar like 2" square, but to save time bandsawing a bunch of material off, just leave it as 2" square. The planer has a big clapper box and it would easily fit. Not a lantern post with a narrow slow.

Other than the bulk of hefting a big bar around am I making a big mistake in beefing up the structure of it? Seems like the main design element is to get the toobit back underneath the clapper box rather than leading ahead of it.

A couple embarrassingly rough sketches to possibly help illustrate...

General idea behind an Armstrong 401...

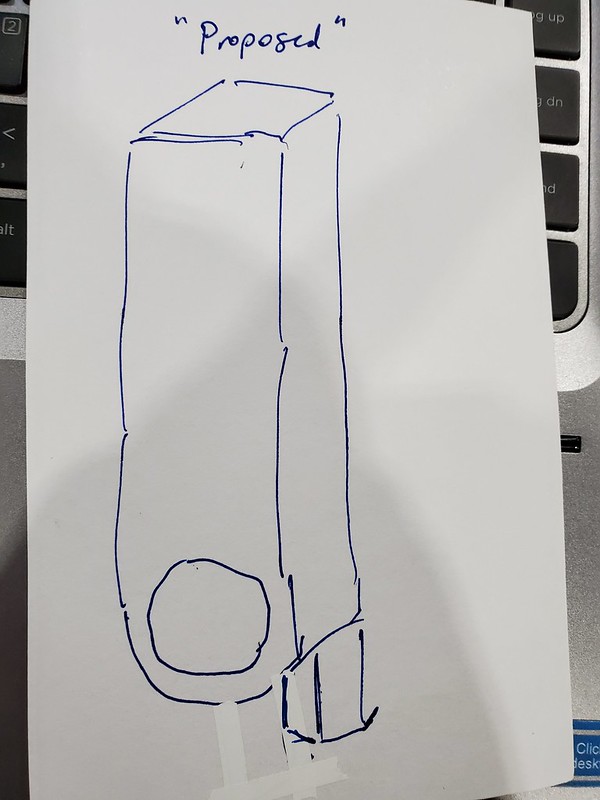

My concept....

Thanks as always for your thoughts and comments!

I'm headed down the road of getting the planer going 24x72 table, Putnam. Need some press brake tooling...

I think I want to use a 1/2" toolbit but don't have the proper holder.

I like the Armstrong 401 design but that's basically for a 3/8" sq toolbit.

I can handle designing it to work, but I have a question about the structure.

The Armstrong 401 has a bulbous head on a "flat bar" shaft. I can see why they wanted to conserve material with either a casting or forging.

I would propose to make it out of a heavy square bar like 2" square, but to save time bandsawing a bunch of material off, just leave it as 2" square. The planer has a big clapper box and it would easily fit. Not a lantern post with a narrow slow.

Other than the bulk of hefting a big bar around am I making a big mistake in beefing up the structure of it? Seems like the main design element is to get the toobit back underneath the clapper box rather than leading ahead of it.

A couple embarrassingly rough sketches to possibly help illustrate...

General idea behind an Armstrong 401...

My concept....

Thanks as always for your thoughts and comments!