metalmagpie

Titanium

- Joined

- May 22, 2006

- Location

- Seattle

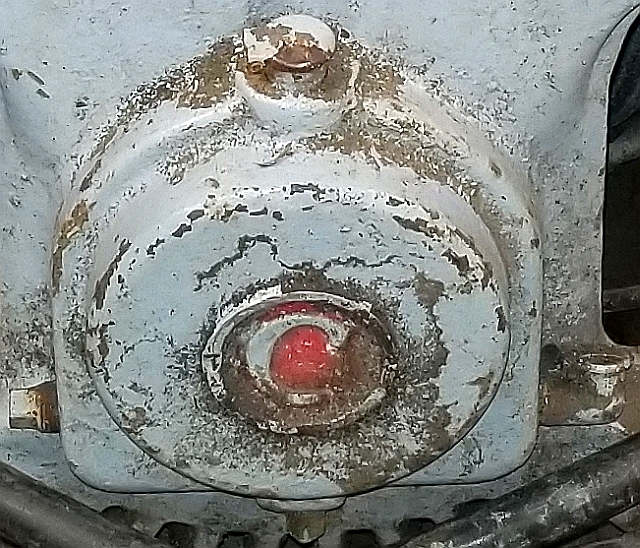

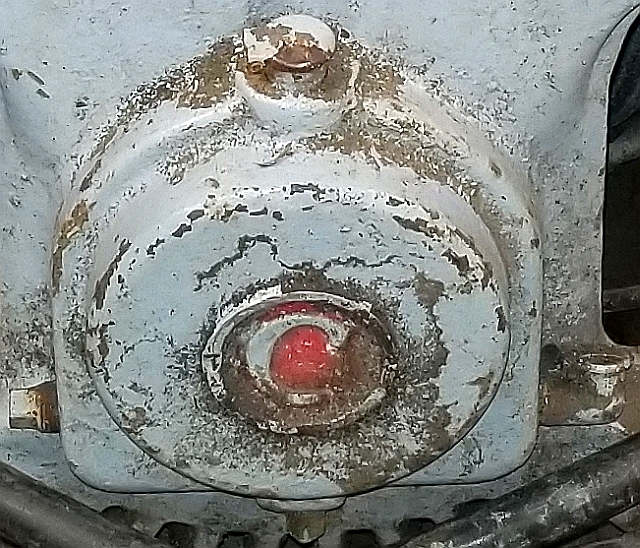

Old ('40s) Century repulsion-start induction-run motor. At each end of the rotor the shaft turns in a sleeve bearing. The sleeve bearing has a slot cut in the top half about 1/4" wide. The bearing sits in a cavity where the bottom inch or so is filled with oil. A metal ring sits in the slot in the sleeve bearing, and is big enough to dip down in the oil. As the shaft turns, the ring slowly turns, bringing oil up to the cutaway slot where it can flow down around the shaft inside the sleeve bearing.

Mine has a 1/2" Gits press fit oil cup at the top center of the oil bath. About at the height of the oil, on one side is threaded a 1/8"NPT Gits oiler. On the other is the first of two 1/8" plugs. The second is bottom center of the oil bath, below the top center Gits cup.

I'm wondering about the use model for these fittings. Obviously, I can add oil in the top center. Redundantly, I can also add it low down on one side. If the oil bath were a clock face the second oil cup would be at 5 o'clock and the upper drain plug would be at 7 o'clock, with the lower drain plug being at 6 o'clock and the upper oil cup being at 12. Here's a picture, sorry for the filth and heavy paint:

My question is: why have two oil cups and two drain plugs?

metalmagpie

Mine has a 1/2" Gits press fit oil cup at the top center of the oil bath. About at the height of the oil, on one side is threaded a 1/8"NPT Gits oiler. On the other is the first of two 1/8" plugs. The second is bottom center of the oil bath, below the top center Gits cup.

I'm wondering about the use model for these fittings. Obviously, I can add oil in the top center. Redundantly, I can also add it low down on one side. If the oil bath were a clock face the second oil cup would be at 5 o'clock and the upper drain plug would be at 7 o'clock, with the lower drain plug being at 6 o'clock and the upper oil cup being at 12. Here's a picture, sorry for the filth and heavy paint:

My question is: why have two oil cups and two drain plugs?

metalmagpie