Galane

Hot Rolled

- Joined

- Dec 6, 2010

- Location

- Idaho, USA

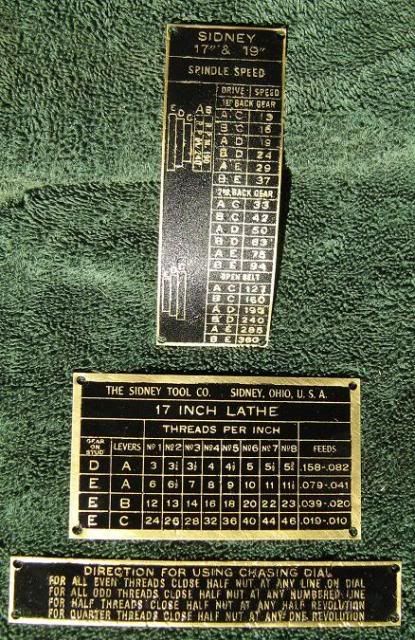

Has anyone done this? I'm working on a Wade 8A (serial 403) and would like to strip the partially gone black paint from the gearbox plate and apply new paint.

What I've found shines up the raised, paint free, areas of the brass while doing little to no damage to the paint is a siaair Velvet 3,000 grit, foam backed polishing pad, soaked in plain water.

The hardest stuff to get off is the oil and dirt concretion. It sticks hard in the recesses of the plates and I'd expect any really tough solvents would also quite happily remove the paint, if they'd touch the compacted crud at all. Repeated soakings in straight liquid dish soap and "chiseling" with a thumbnail is slow going but it does eventually get the stuff off.

What I've found shines up the raised, paint free, areas of the brass while doing little to no damage to the paint is a siaair Velvet 3,000 grit, foam backed polishing pad, soaked in plain water.

The hardest stuff to get off is the oil and dirt concretion. It sticks hard in the recesses of the plates and I'd expect any really tough solvents would also quite happily remove the paint, if they'd touch the compacted crud at all. Repeated soakings in straight liquid dish soap and "chiseling" with a thumbnail is slow going but it does eventually get the stuff off.