JHolland1:

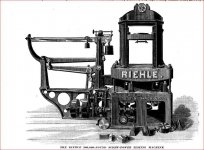

The thread about the Riehle testing machines brings back memories of Brooklyn Technical HS. In our junior year in the mechanical course of study at 'Tech, we took a basic strength of materials course. This course consisted of some basic theory, and labs. The Strength of Materials lab at Tech was well equipped, and it had two Universal Testing Machines- a Baldwin/Southwark rated at something like 100 tons, hydraulically operated, and a Louis Schopper UTM of a bit lesser capacity, mechanical/screw operated. The Schopper was a prewar machine, made in Leipzig. We had two Riehle testing machines with the beam balances, a torsion tester, and a Charpy impact tester in the lab. The basic course consisted of learning about the stress-strain relationship for steel, and pulling a tensile specimen then plotting the stress-strain curve and calculating the modulus of elasticity. We advanced to pulling tests on rivited joints, as well as tests on sheet metal specimens, then compression tests on concrete cylinders and tensiles on mortar "dogbone" specimens, along with torsion tests to get shear stress in round shafting steels, and charpy impact tests. We were also introduced to basic strength of materials theory, learning about bending moments, moments of inertia, and the basic design of structural steel beams and columns. Somewhere in all of it, a lab partner and I were assigned to go pull some tensile tests on samples of thin plate using one of the Riehle testing machines. We did not use the power drive. My lab partner cranked slowly and steadily to increase the tension on the specimen held in the machine's jaws. I cranked carefully to keep moving the counterpoise (I think that is what it was called) moving out on the balance beam. As long as the beam stayed in a "floating" position (like the oldtime doctor's office scales or "steelyard" type balances), the load reading was valid. A third person kept logging the readings for amount of deformation (gotten with an "Ames gauge"- a long travel dial indicator) and load, based on where the counterpoise weight was. I remember our teacher, a man named Mr. Durso, came over to us and complimented us on being able to keep the Riehle machine in a smooth and steady loading condition with the balance beam floating rather than hopping up and down.

It was an excellent course, and we had, as I recall, a second term of strength of materials. More labs, and more time with the old testing machines. Rivited specimens were made in the school's structural fab shop, using A-36 steel plate and 5/8" and 3/4" hot-driven rivets. We had to calculate the efficiency of each joint, some being lap joints, some being butt/welt plate joints, and determine the safe working loads, then test each joint to destruction and determine failure mode. We also had to machine ASTM 0.505" diameter specimens and pull tensiles on them, using materials such as 4140 steel, 1020 steel, bronze and aluminum. We got into column design theory and actually tested a sample column to see "Euler buckling" develop.

The Riehle testing machines were probably from when Tech was built (1920's), and they were massive, being mounted at floor level with no pedestal or legs needed.

I've read of a few testing labs in the USA that still have the old Riehle balance-beam type testing machines and keep them in use. We used machinist's dividers and a 6" Starrett machinist scale, a 6" vernier caliper or the Ames gauge to get the amount of deformation in a specimen. Even with the use of dividers and the Starrett rule, we were able to get accurate enough data to plot our first stress-strain curve for 1020 steel and calculate a modulus of elasticity that correlated with published values. We were kids of maybe 15 or 16, and there were no computers nor pocket calculators. We used slide rules and longhand calculations, and we had to present our data on engineering graph paper (finely ruled graph paper), done in 4H pencil, with lettering and calculations done "in accordance with the graphic standards of the Mechanical Drawing Department of Brooklyn Technical HS". Turn in work done any old way, even if it was complete and accurate, and the teachers would reject it or rip it up on the spot.

I still wonder if the old strength of materials lab exists at Brooklyn Technical HS. The school has been watered down as far as standards, gutted and denutted as far as the curriculum so it barely resembles the school it was when I attended it. Using the testing machines and seeing the basic principals of strength of materials happen before my eyes was one of the best parts of my education. 4 1/2 years of engineering school followed, and we never went near a testing machine, just loads of theory. Riehle used to be out near Philadelphia, while Southwark (their competitor) was in that same area, as was Tinius Olsen Testing Machine Company- it came back to me that we used a Tinius Olsen testing machine for testing concrete cylinders. The Louis Schopper UTM was a really fine machine, and I marvelled at it even as a kid. It had huge screws to work the head of the machine and apply load, and the castings were all well finished and enamelled. The machined parts were all highly finished and polished, and the control handles were all nickel plated. When we ran tensile tests in the Louis Schopper UTM, we could barely see the huge screws turning to apply the load. I remember us kids looked at those huge screws and wondered what machinist had to cut those threads and how he did it. We were already cutting screw threads in machine shop classes and learning about power transmission threads in machine design, so seeing those huge screws in the UTM had us talking and wondering. Different times, different breed of kids. No cell phones, no texting, no Ipods, no computers. We marvelled at all of what we saw, did and learned in the Strength of Materials courses. We got into more advanced structural calculations in the classroom. It was an amazing set of courses, and taught me much that I use to this very day.