TorqueHead

Plastic

- Joined

- Oct 22, 2021

Hello Everyone!

I am a retired machinist and just joined this forum today.

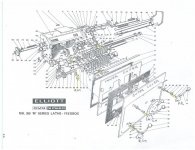

Hoping to find a manual or parts list for my Elliot Cardiff lathe known as the Major. It has a center height of 7.5" and a gap bed of 60".

I need to get into the speeds/feeds gearbox to do some repairs but without knowing what is inside I am not sure how it comes apart. The cover seems solidly stuck and I do not want to break it. The cover appears to sit on top of a frame.

I would really like to understand what is inside. If I cannot find manuals perhaps someone has photos taken during their restorations?

Cheers,

Tom

I am a retired machinist and just joined this forum today.

Hoping to find a manual or parts list for my Elliot Cardiff lathe known as the Major. It has a center height of 7.5" and a gap bed of 60".

I need to get into the speeds/feeds gearbox to do some repairs but without knowing what is inside I am not sure how it comes apart. The cover seems solidly stuck and I do not want to break it. The cover appears to sit on top of a frame.

I would really like to understand what is inside. If I cannot find manuals perhaps someone has photos taken during their restorations?

Cheers,

Tom